Vsub, Factory wiring of open loop vfd drive – Tjernlund VSUB Series Universal Blowers for Combustion Air or Draft 8504114 User Manual

Page 11

10

STATIC PRESSURE METHOD TO VERIFY ROTATION:

1. Turn OFF the service switch to all of the heating appli-

ances so they will not run during this test.

2. Adjust the heating appliance balancing baffle(s) or

blast gate(s) to the closed position.

3. Turn the speed adjustment knob on the VFD to the 3:00

o'clock position, Hz_____. Activate the VSUB Blower by

installing a jumper between positions MS3 and MS4 on

the VFD terminal strip. Record the static pressure in the

vent pipe using a manometer or digital pressure gauge

in. W.C. _____. Disrupt power to the VFD and wait 60

seconds before continuing to avoid electrical shock.

4. Locate the two wires within the VFD enclosure that are

connected with pink quick connects. Separate the quick

connects and reconnect the White/Brown lead attached

to the filter board to the previously unconnected lead

from VFD terminated with pink quick connect.

Reestablish power to the VFD.

5. Perform steps 3 & 4 above. Important: VFD must be at

same Hz _____ (speed) as the initial test. The rotation

direction that yielded the higher static pressure is the

correct rotation. If the earlier static pressure result was

the higher pressure result, perform step 4 to reverse the

rotation. Remove jumper from the MS3 and MS4 posi-

tions on the VFD terminal strip.

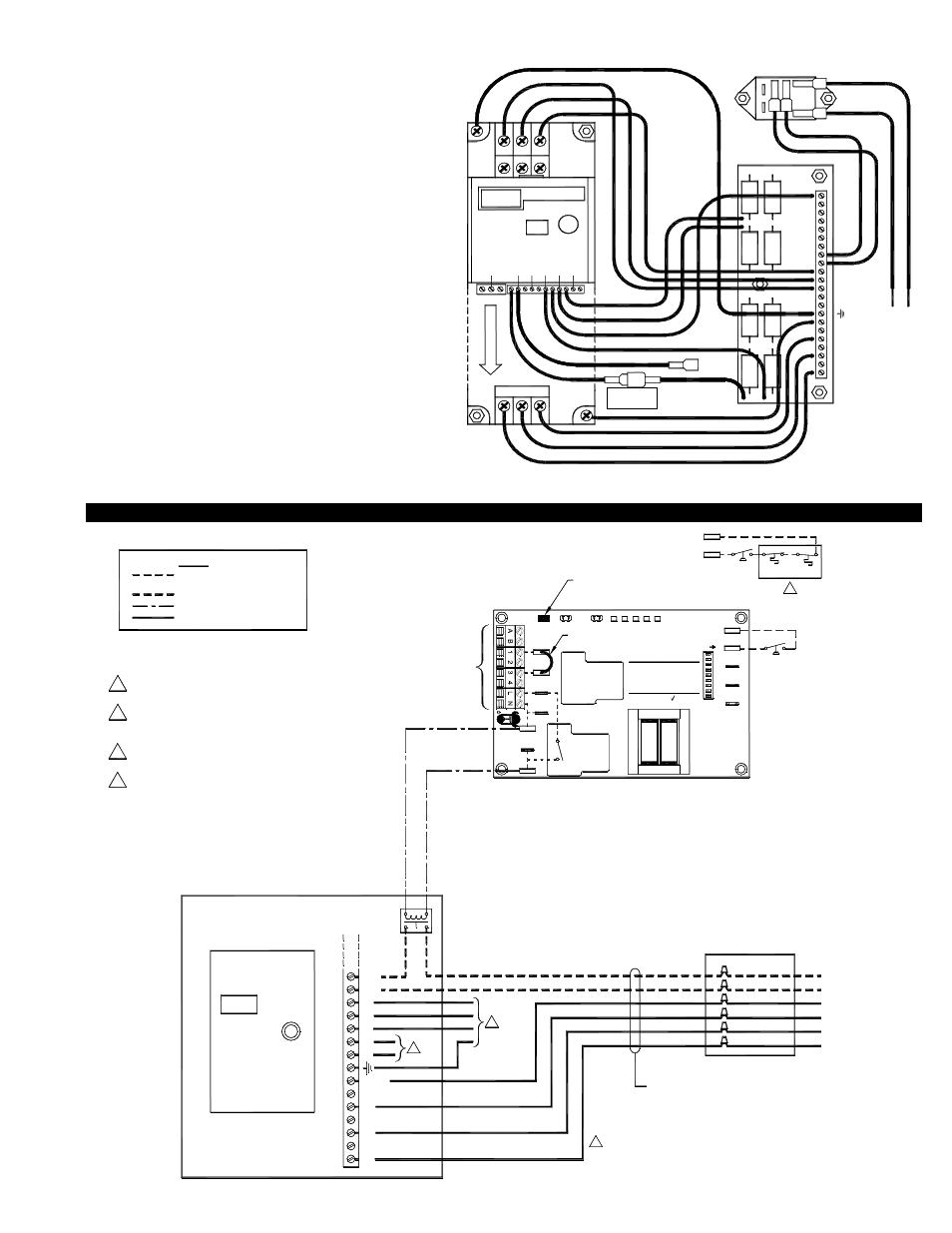

WIRING VSUB FOR A ADJUSTABLE-FIXED SPEED APPLICATION (MANUALLY ADJUSTED WITH AN OPEN LOOP VFD)

WARNING:

IN

C

.

7. For appliance interlock, use UC1 instructions.

"O" means "Open Loop"

VFD- _ _ _ _ _ _ _ O

TJERNLUND DRIVE MODEL

Check motor rotation

(See VFD instructions)

VFD

MGND

M3

M2

M1

MS4

MS3

L3

F1

F2

L2

L1

ADJUST

SPEED

RELAY

Voltage from F1 & F2 is the same as voltage to L1 & L2.

DO NOT run input and output wiring in the same conduit.

All wiring must be in metal conduit (best) or shielded cable.

230 VAC OR 460 VAC

5 VDC BOARD-GENERATED POWER

DO NOT SUPPLY POWER!

115 VAC

NOTES:

FIGURE 8089002 03/23/04

6.

5.

3.

2.

1.

LEGEND:

24 VDC

FOR APPLIANCE INTERLOCK

SEE UC1 INSTRUCTIONS

INFORMATION

100' (30m) @ 460 VAC

All wiring must be in metal conduit

or shielded cable. Maximum length

300' (91m) @ 230 VAC and

BOX AND WHIP

WEATHERPROOF

3

1

ORANGE

BLACK

BLACK

GREEN

BLACK

BLUE

VSUB

will be off if power has been removed from the control.

in personal injury and/or equipment damage. LED #5 (RED)

Remove power to Universal Control when installing, servicing,

or changing dip switch settings. Failure to do this may result

P2

P1

C

G

N

D

F

RED JUMPER POSITION MUST BE THE SAME

AM

BER

GR

EEN

GR

EEN

CALL

INTERLOCK

RELAY

TJ

E

R

N

L

U

N

D

PR

O

D

U

C

T

S

,

9183006

MTR

M

NO

COM

XL

R

XN

N

J1

J2

K2

JUMPER

PRE-PURGE SETTINGS

OPEN PROVER OPTION

POST-PURGE SETTINGS

K1

7

(9)

9

8

(1 - 2)

(3 - 8)

26

5

34

ON

1

AS APPLIANCE INTERLOCK VOLTAGE.

IMPORTANT:

115V

UC1

24V

DRY

LED1

LED3

RE

D

LED5

RE

D

LED4

LED2

FFP-1

PSA-1

4

PSA-1

P1

P2

Verify that the VSUB motor is wired for the output voltage

from the drive. If not correct, severe damage will result.

Verify that the input voltage matches the drive's nameplate

BEFORE applying power or severe damage will result.

4. Use FFP-1 when using VSUB as a combustion air provider.

Auxiliary powered devices at F1 & F2 (e.g. the included

VSUB motor heater) may require a step-down transformer.

2

D P

IMPORTANT:

in the installation manuals.

Perform a safety interlock and operational test as outlined

FIGURE 8084002

M1

M2

M3

MGND

L1

L2

F2

F1

L3

MS4

V1

S2

S1

MS2

MS1

V3

V2

YELLOW

RED

VIOLET

GREEN

BROWN

BLUE

GRAY

WHITE

ORANGE

BLACK

BLACK

BLACK

GREEN / YELLOW

E

X

P

L

O

D

E

D

U/T1 V/T2 W/T3

_

+1

+2

R/L1 S/L2 T/L3

MA

MB

MC S1

S2

S3

S4

S5

SC

FS

FR

FC

AM

AC

WHITE / RED

WHITE / BROWN

MS3

YELLOW

ORANGE

BLACK

WHITE

FACTORY WIRING OF OPEN LOOP VFD DRIVE

PINK QUICK

CONNECT