Tjernlund SS2 SideShot with UC1 Universal Control (Version X.02) 8504105 Rev 07/02 User Manual

Page 5

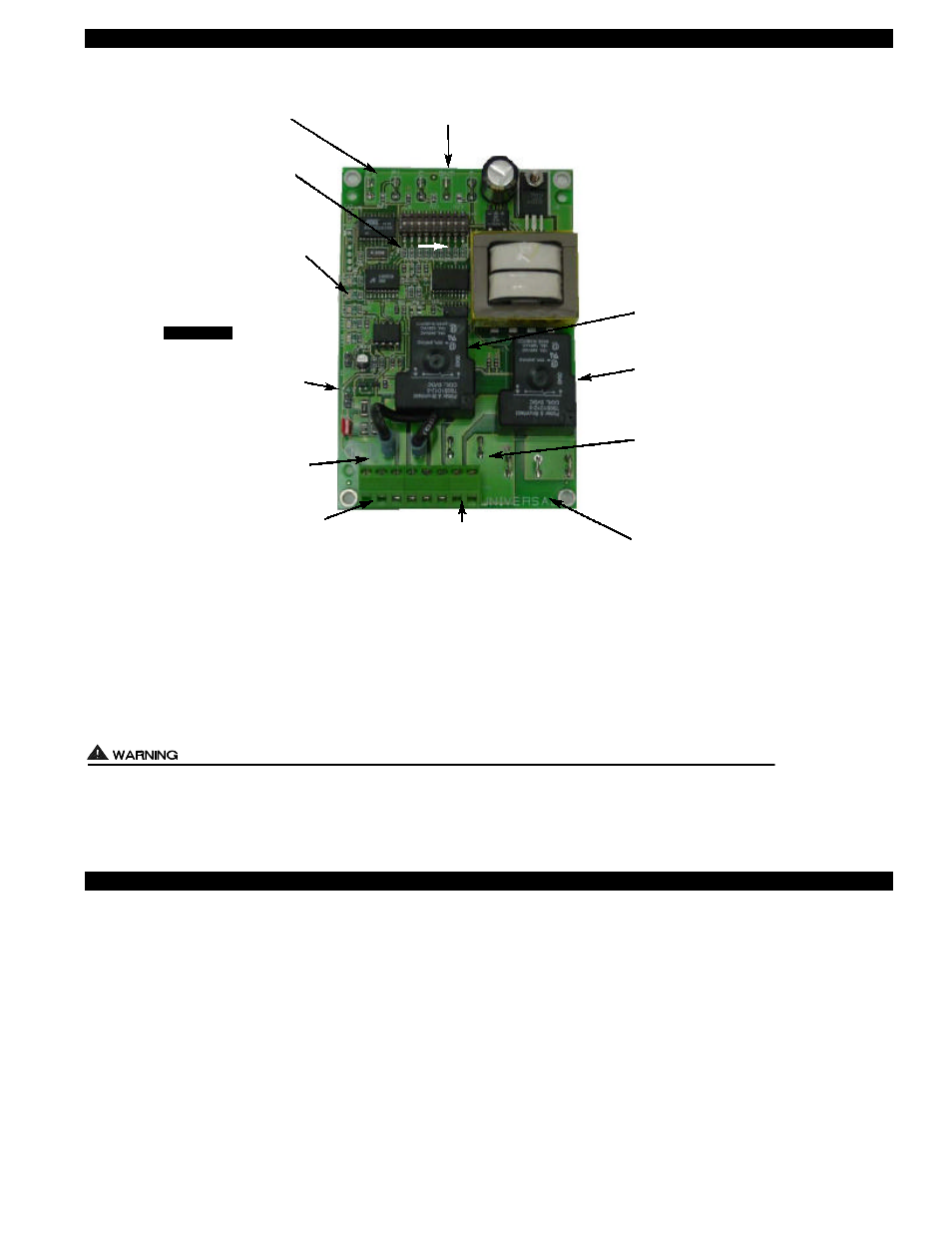

SS2 WITH INTEGRAL UC1 UNIVERSAL CONTROL BOARD FEATURES

# 1.

Power supplied by board. Do not supply power to this area or control damage may result.

# 2. Do not supply power to the appliance interlock block with the call selector in the “DRY” position.

Control damage may result if power is supplied.

# 3. Circuit protection must be provided by the installer. 16 Amps is the maximum current allowed for this device at terminal L.

V

A 15 Amp circuit breaker is recommended.

V

ETI

LED STATUS & FAULT INDICATORS

LED INDICATOR LIGHTS

LED #1 (Amber) Appliance call for heat.

LED #2 (Green) Safety circuit through P1 & P2 (SS2 Limit & Fan Prover) is verified “Open” upon start-up. Burner circuit is

energized with contact closure from terminal 3 to 4. Also verifies SS2 prover & limit are closed during run cycle.

LED #3 (Green) Power switched to SS2 Motor & Cooling Fan from L to MTR & M.

LED #4 (Red)

Status indicator.

LED #5 (Red)

115 VAC power supplied to board. Also used as status indicator.

LED INDICATOR LIGHT STATUS & FAULTS

LED #4 & #5 Flashing Alternately

= Prover start up fault. SS2 Prover contacts “Closed” across P1 & P2 upon appliance call

before SS2 is turned on. Prover status check must be activated, see page 5.

LED #4 & #5 Flashing in Unison

= Fan Prover circuit is “Open” longer than 60 seconds on start-up or 10 seconds during run

cycle. Prover or Limit contacts are not staying “Closed” across P1 & P2 safety circuit.

LED #4 Flashing & #5 on Continuous = System in Pre-Purge. (Pre-Purge options 0, 15, 30, 60 seconds)

LED #5 Flashing & #4 on Continuous = System in Post-Purge. (Post-Purge options 0, 30 seconds or 1, 2, 4, 8, 16 minutes)

IMPORTANT: To reset faults, verify fault by checking the LEDs and then remove call for heat.

4

LED STATUS LIGHTS

See “LED Status & Fault

Indicator Section” for details.

LED 1 (AMBER)

LED 2 (GREEN)

LED 3 (GREEN)

LED 4 (RED)

LED 5 (RED)

DRY

24 V

115 V

J1- J2 CALL

JUMPER

Used when the call signal is

used as the “proven” return

signal to the appliance. See

wiring section for details.

APPLIANCE INTERLOCK

TERMINAL BLOCK (A-B, 1-4)

A - B - Dry Contact call. 3 mA @ 5VDC.

SEE WARNING # 1.

1 - 24 or 115 VAC intercepted call.

IMPORTANT: RED voltage jumper must

match intercepted call voltage.

2 - 24V common or 115V Neutral.

3 - Common terminal to appliance relay con-

tacts. IMPORTANT: J1-J2 jumper routes

call voltage at terminal 1 to 3. Remove

J1-J2 jumper if a different voltage source is

provided to terminal 3.

4 - Normally open terminal of appliance relay.

Will be energized from terminal 3 if safety

circuit is “proven”.

L / N - 115 VAC POWER

SUPPLY BLOCK

115 VAC / 50-60 Hz

Circuit protection provided by installer.

SEE WARNING # 3.

MTR & M LOAD TERMINALS

FROM VENTER MOTOR RELAY

Used to drive SS2 Motor & Cooling fan.

1 HP MAX LOAD across terminals MTR & M / N.

XL / XN AUXILIARY DEVICE

POWER TERMINALS

115 VAC - Maximum of 0.15 Amps.

Only connect to Tjernlund auxiliary devices.

SEE WARNING # 1.

APPLIANCE INTERLOCK

RELAY

1 HP MAX LOAD across

terminals 3 & 4.

VENTER MOTOR RELAY

1 HP MAX LOAD from

terminals L to MTR & M.

APPLIANCE

INTERLOCK

RELAY

VENTER

MOTOR

RELAY

A B 1 2 3 4 L N

J1 J2 XL XN

P1 P2 C GND F

(1 9)

N M MTR

P1 - P2 SAFETY CIRCUIT

TERMINALS

1 mA @ 5VDC.

SEE WARNING # 1.

C, GND, F AUXILIARY DEVICE

COMMUNICATION TERMINALS

2 mA @ 5VDC. For Tjernlund MAC1E or

MAC4E auxiliary devices. SEE WARNING # 1.

APPLIANCE CALL

VOLTAGE SELECTION

Place RED voltage jumper in

proper location based on

appliance call interlock volt-

age. SEE WARNING # 2.

IMPORTANT

DIP SWITCH SETTINGS

Pre-Purge (1-2)

Post-Purge (3-8)

Prover status check (9)

See “Pre / Post Purge &

Prover Status Check Dip

Switch Settings”.