Tjernlund SS1 SideShot with UC1 Universal Control (Version X.04) 8504102 Rev C 02/04 User Manual

Page 18

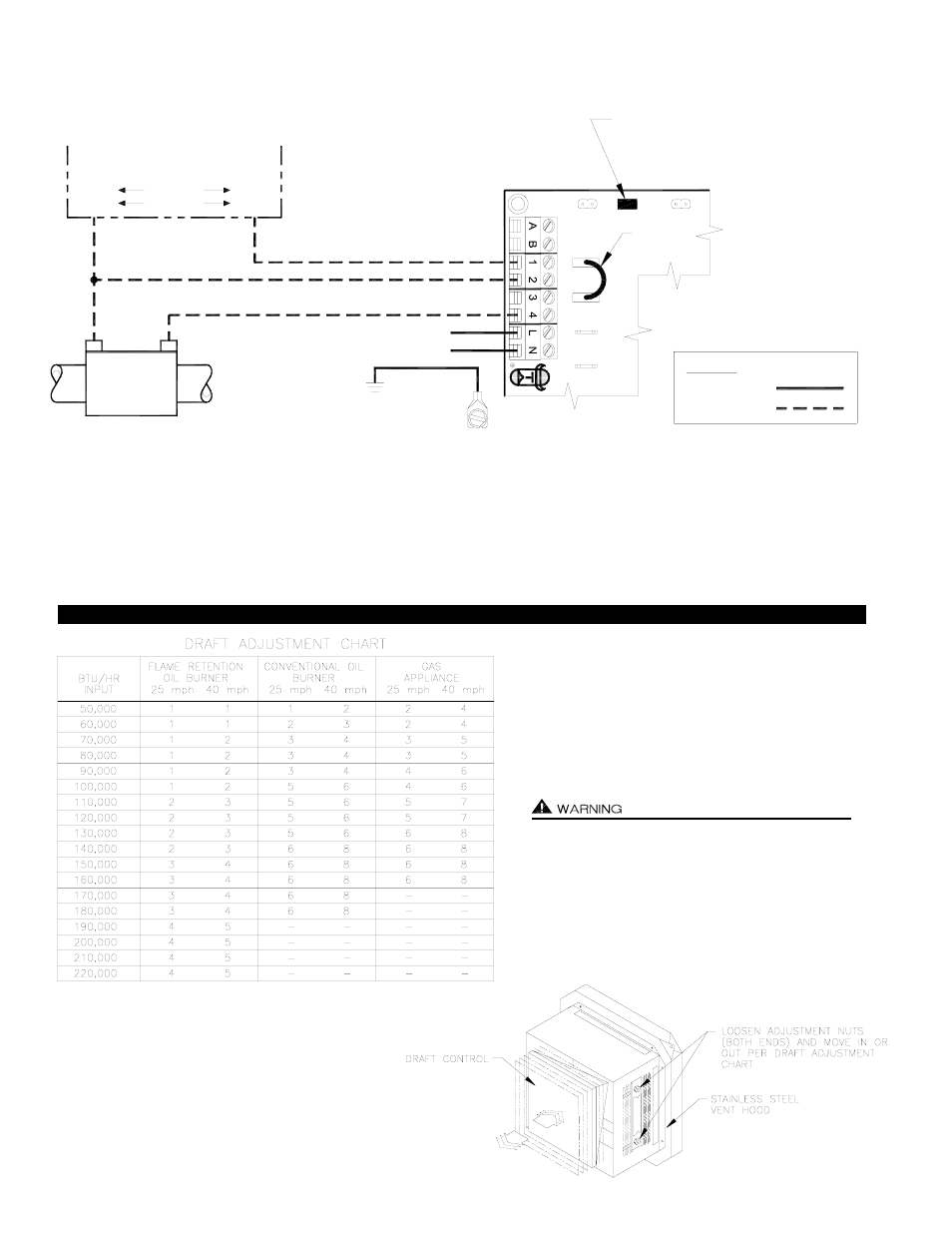

DRAFT ADJUSTMENT PROCEDURE

17

SIDESHOT WITH INTEGRAL UC1 UNIVERSAL CONTROL CONNECTED

WITH A 24 OR 115 VAC STANDING PILOT

115V

24V

DRY

OF FURNACE/BOILER

INTERNAL CONTROLS

24V OR 115V GAS VALVE

HOT

COM

B2

COM

TR

Aquastat

T-stat

TH

HOT

B1

XL

U

N

IVER

SAL C

O

N

T

R

O

LLER

XN

J1

J2

D/N 9183046-1

24 OR 115 VAC

LEGEND:

CALL

JUMPER

115 VAC

50/60 Hz

SUPPLY

115 VAC

SPADE TERMINAL IN ELECTRICAL BOX.

GROUND

CRIMP GROUND WIRE TO GROUNDING

IMPORTANT:

RED JUMPER POSITION MUST BE THE SAME

AS APPLIANCE INTERLOCK VOLTAGE.

IMPORTANT:

1. Remove the wire on TH or HOT of gas valve and connect it on #1 on UC1 terminal block.

2. Connect #2 on UC1 terminal block to TR or Common.

3. Connect #4 on UC1 terminal block to TH or HOT on gas valve.

4. Connect 115 VAC supply voltage to L & N terminals on UC1. Installer must supply overload and disconnect protection.

5. Crimp ground wire to grounding spade in SS1 electrical box.

6. Make sure RED voltage jumper on UC1 is on 24V or 115V depending on control voltage.

NOTE: If burner primary control goes out on lockout, the SideShot will continue to run as long as a call for heat is present.

NOTES: All draft adjustments are approximate. This

chart is to be used for initial draft adjustment only.

Subsequent draft adjustments may be required to com-

pensate for various field conditions: wind, vent pipe

resistance, building pressure, multiple appliances, etc.

BTU/HR input ratings assume 30% or less excess air

for flame retention burners and 50% to 100% excess

air for conventional oil burners.

Do not exceed the recommended BTU/HR input range

of the SideShot.

Under no circumstances shall the minimum draft

adjustment be used for the larger input range of this

product.

Improper draft adjustment may result in the dispersion

of flue products/carbon monoxide into the building interior.

DIAGRAM P