Installation – Thetford EV704D Series User Manual

Page 3

INSTALLATION

In preparing the DE-704D for installation, the following areas

should be considered:

1. Adequate ventilation.

2. Sizing of supply wire and fuse protection.

3. Direct wiring from battery to avoid electrical interference

with other equipment.

4. Provisions to prevent battery run-down.

5. Provide correct voltage and frequency for AC operation.

6. Proper grounding to prevent electrolysis for marine applica-

tions.

These instructions provide a guide to insure compliance to the

situations listed above.

The Norcold dual voltage refrigerator is designed for the recrea-

tional vehicle, Marine industry, as well as under the counter instal-

lations. A typical R.V. installation, for instance, requires the refrig-

erator to operate on 12 volt DC while in transit and 120 volt AC

while parked. The Norcold refrigerator automatically converts from

one power source to the other.

Unlike the absorption-type refrigerator, which requires a constant

heat source for efficient operation, your dual voltage refrigerator

operates on the same principle as the standard domestic refrigera-

tor. That is, it has an electrically operated compressor and uses

freon as its refrigerating medium.

Unit Location

Be sure the refrigerator is not installed in direct sunlight, or near

a gas stove, heater or other heat generating sources. A flanged

mounting frame is provided around the front of the refrigerator

cabinet to allow build-in installation.

The refrigerator must be located and secured on a solid surface

within the vehicle.

The opening cut-out dimensions for the refrigerator are listed in

Table 1. Measure for the opening and determine if you have the

proper clearances for installation. There is no need for allowing an

area around the cabinet for additional insulation as the Norcold

refrigerator is well insulated and requires no additional insulation.

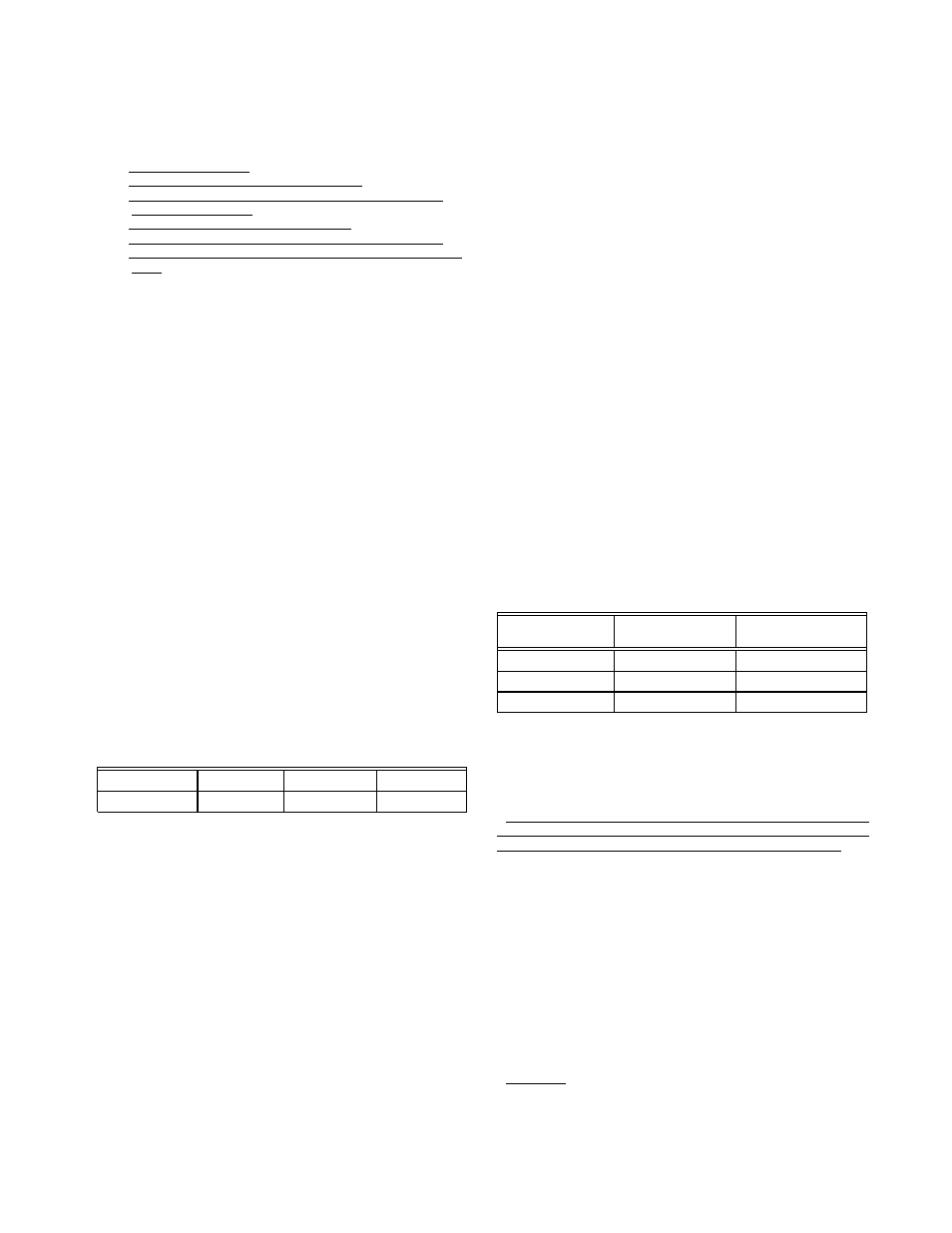

Table 1

Before installing the cabinet into the opening, check to see if the

AC power supply cord of the unit is properly connected to the AC

wall outlet and if the DC supply should be connected. In many

cases, the DC supply can be connected from outside the vehicle

by means of the vent or access door.

Place the refrigerator into the wall opening and secure it in place

by fastening the mounting flange to the wall through the holes

provided.

Please note the perforated access panel at the front base of the

refrigerator. This panel allows air movement to flow under the

cabinet and over the power supply for cooling.

The rear side of the unit must not be closed off without providing

ventilation. At least 50 sq. inches must be provided to allow re-

jected heat to escape.

For travel trailers, a small louver-type vent of approximately 4" x

16" area may be installed at the top and at the bottom of the

exterior wall of the vehicle for outside venting purposes.

A combination of a roof jack and lower vent or two side vents

offers adequate venting for high outside ambient temperatures.

The more air circulating over the condenser (located at rear), the

more efficient the refrigerator will operate. Failure to provide the

necessary ventilation will result in poor refrigeration. If operation at

low outside ambient temperatures is necessary (below 23° F) all

exterior venting must be covered to prevent serious performance

loss.

When installation incorporates exterior venting and operation at

low outside ambient temperatures is necessary (below 23° F), ex-

terior venting must be covered or reduced cooling efficiency in

cabinet will result.

Power Supply

Provisions are made for connection of either 12 volts DC or 120

volts AC to the refrigerator. If both 12 volts DC and 120 volts AC

are simultaneously supplied, a special relay in the refrigerator

power supply allows the unit to run on 120 volts AC. To convert to

DC power, the AC supply is simply disconnected.

DC Power Connection

The DC supply connection is located behind the perforated ac-

cess panel at the bottom front of the unit. Remove the screw from

the top center of the access panel and remove the panel. The DC

terminal box is located in the control power supply assembly. The

positive and negative DC supply connections are located in this

terminal box. The terminal box is provided with knock-out holes for

routing the DC lead wires through the side of the terminal box.

The size of the wire from your 12 volt DC battery is dependent

upon the distance between the refrigerator and the battery. Refer

to Table 2 for wire size.

Table 2

This recommended wire size is to prevent a voltage drop at the

refrigerator which is critical to DC performance.

Use of wire sizes smaller than those listed may cause excessive

DC running time, shorter battery life, and poor performance due to

line loss.

It is important that the 12 volt, DC supply wires be connected

directly to the battery and that the wires are dedicated to the re-

frigerator (other appliances are connected by separate wires). This

practice minimizes the possibility of radio and T.V. interference.

Twisting the positive and negative supply wires further helps to

nullify the induction effects which could further add to radio/T.V.

interference.

To the leads located in the terminal box, connect the positive

battery lead to the red wire and the negative battery lead to the

black wire (important to be well insulated). These splices should

be soldered or connected by means of an approved splice con-

nector. Tape the spliced connections generously before replacing

the terminal cover box.

A 15 amp fuse should be installed as close to the battery as

possible in the positive wire leading to the refrigerator. This fuse

will protect the wiring from the battery to the refrigerator in the

event of a short circuit.

CAUTION:

DO NOT OPERATE REFRIGERATOR ON BATTERY ALONE.

THE BATTERY MUST HAVE A CHARGING MEANS SUCH AS

AN ON-BOARD GENERATOR; IF NOT, THE BATTERY WILL

DISCHARGE IN A SHORT PERIOD OF TIME.

Refrigerator Cut-Out Opening (inches)

Model

Height

Width

Depth

DE-704D

33 1/8

22

21 3/4

12 Volt Supply Wiring And Fuse Size

Min. Wire

Max. Fuse

Size

Size

0 -12’

14 AWG

15 AMP

12’ - 20’

12 AWG

15 AMP

over 20’

10 AWG

15 AMP

3