Symtech CVA3 EZ User Manual

Page 5

5

Move glide plate up and down the mast through its full motion, by

depressing handle.

2.3 OPTICAL ALIGNMENT HEAD

Remove optical alignment head from shipping carton.

Inspect for any damage that may have occurred during

shipment i.e. lens, case, etc..

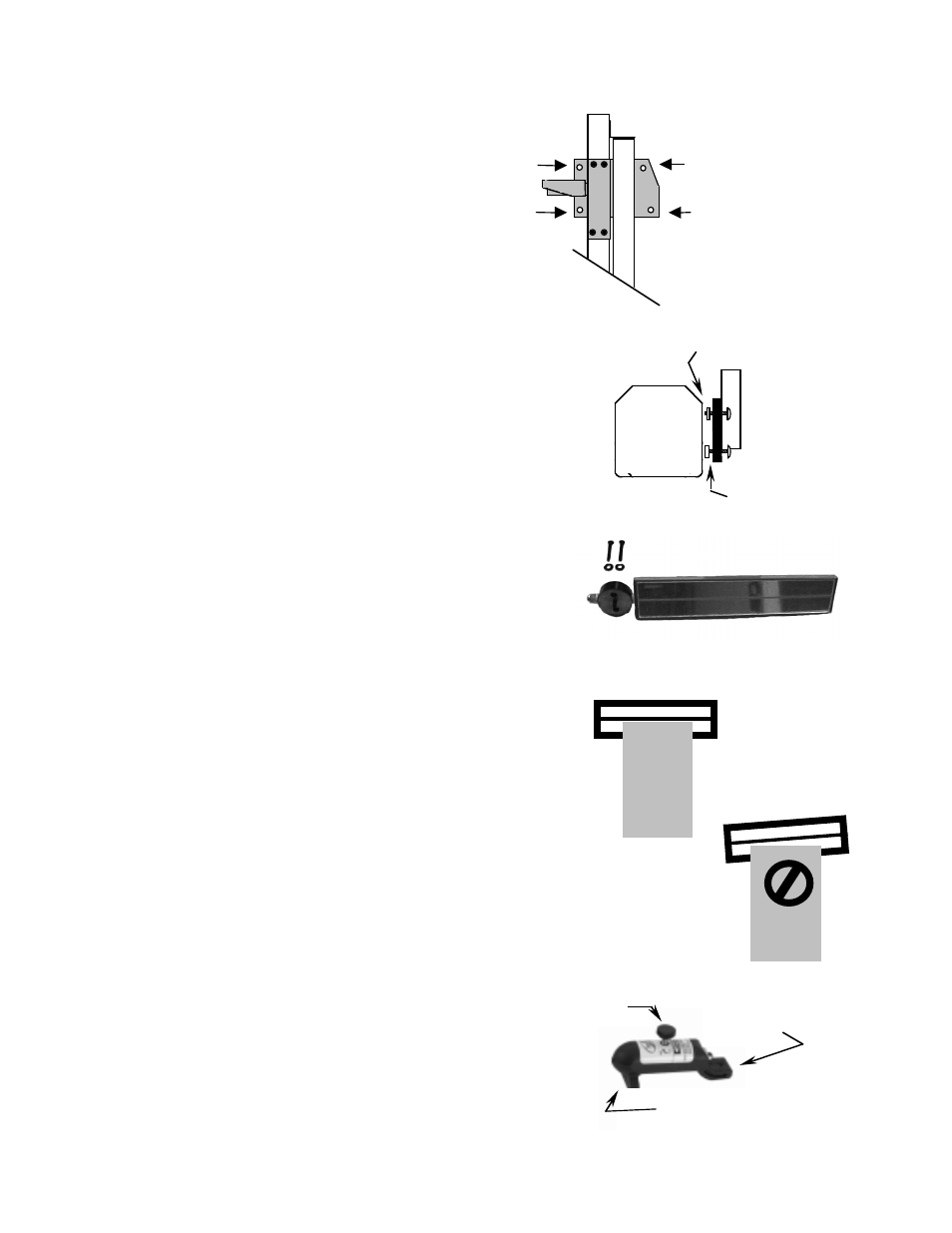

Attach optical alignment head to the mast glide plate by

aligning mounting holes of glide plate with the holes in

the optical head. Insert _ x 20 x _ allen head machine

screws through glide plate, place a _ x _ nylon spacers

on each upper screws, place a _ x

1

/

2

nylon spacers on

each lower screws, attach optical head and tighten

securely.

Remove protective paper covering from viewing window

on top of optical head.

Move optical head through the full range of movement to

assure of smooth operation.

2.4 VEHICLE ALIGNMENT MIRROR

Vehicle alignment mirror assembly is

enclosed

in the accessories box.

NOTE: Mount mirror assembly so that unit is

located directly over the optical head.

Insert 2, _ x 20 x 1

1

/

2

screws (Small Parts

Package) into mirror calibration block and attach all

to top of mast.

DO NOT TIGHTEN. Tighten to a tension that

allows for sufficient movement during calibration.

After calibration has been performed tighten

securely.

NOTE: Sighting unit must be calibrated to the optical head prior

to alignment of headlamps.

2.5 SIGHTING UNIT CALIBRATION

Calibration of sighting unit must be performed prior to alignment of

headlamps.

Raise optical head of CVA 3

EZ

to the approximate center of travel

of mast.

Turn the sighting unit until you can see the reflection of the front

edge of the optical head. Line on mirror should line up with the

front edge of the optical head.

If line does not line up with the front edge of optical head, rotate

mirror assembly until line is parallel with front of optical head.

Tighten screws.

It is important that periodical checking of calibration of the vehicle

alignment mirror be performed, to assure customer satisfaction.

2.6 FLOOR SLOPE LASER

The floor slope laser assembly is factory calibrated, DO

NOT turn the level adjustment set screw which is at the

back of laser assembly.

The laser is used for floor slope measurement only. Remove

laser after floor slope measurements have been recorded

Glide

Plate

_ x _ Black

Nylon Spacers

Optical

Head

IN

Calibration

OUT of

Calibration

Optical

Head

On / Off

Knob

Level Adjuster

Set Screw

Fixture

Placement Pin

_ x 20 x _

Allen head

Optical

Head

_ x _ White

Nylon Spacers