Instructions, Warning, Tine or scrap grapple bucket installation – Modern AG Grapple User Manual

Page 10: Removing the tine or scrap grapple bucket

10 - Grapple

ASSemBly SeCTiON

ATTACHmeNT TO Prime mOver

Improper attachment of the Tine or Scrap Grapple

Bucket could result in injury or death. Do not operate

this product until you have positive indication that

the attachment is securely mounted.

1. position the attachment on a level surface.

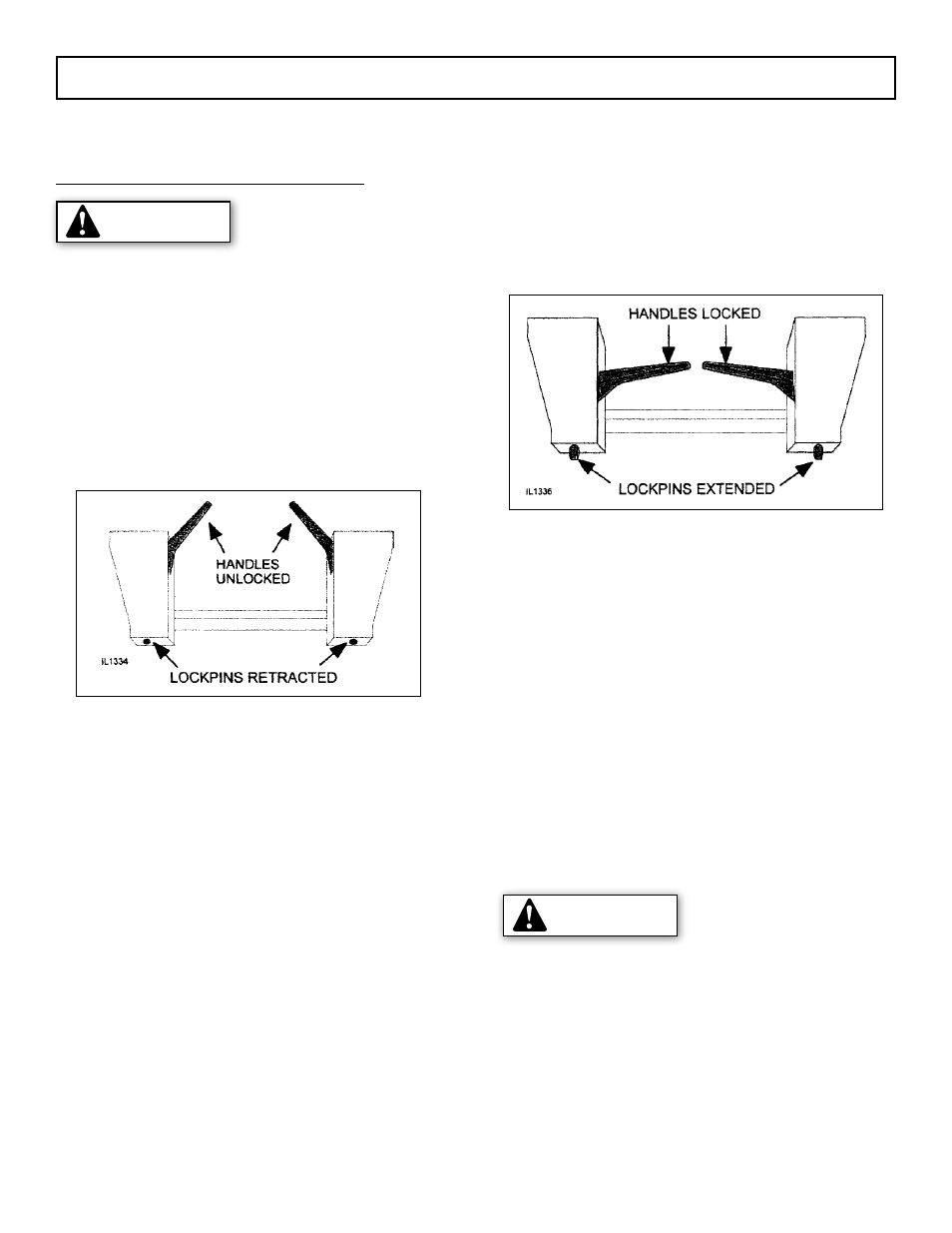

2. The quick attach coupler handles should be in

the unlocked position with lock pins retracted,

Figure 2.

Figure 2. Quick Attach Coupler Handles - Unlocked

3. Enter the prime mover. Fasten seat belt, start

engine. Disengage the parking brake.

4. Follow the attaching procedure in the prime mover

owner’s manual. Align the attachment mechanism

with the mounting on the grapple bucket, attach

to the prime mover or loader.

5 . Engage the parking brake and shut down the

prime mover. Be sure to relieve pressure to the

auxiliary hydraulic lines.

6.

Unfasten safety restraints and exit the prime

mover.

7. Make sure the hydraulic couplers are clean. Connect

the hydraulic lines to the prime mover. Twist the

collar of the quick couplers one-quarter turn to

secure hydraulic connections. If attachment unit is

being installed on a tractor loader, purchase proper

couplers and hoses as required and attach to the

loader as per the manufacturers instructions.

8.

Engage the latching mechanism to secure

attachment to loader. The lockpins must be

completely extended and secured into the retaining

slots provided on the attachment. Figure 3.

Figure 3. Attachment Coupler Handles - Locked

9. Re-enter the primer mover. Fasten seat belt and

re-start engine.

10. Carefully raise the loader and cycle the rollback/

tilt cylinders to check clearances and to ensure

that the attachment is securely mounted.

11.

Cycle the grapple clamp hydraulic cylinders

several times full stroke to work the air out of the

cylinders.

NOTE: When shipped, the hydraulic cylinder(s) on this

product contained air. Failure to remove all the air from

the hydraulic cylinder(s) can cause uneven, jerky cylinder

movement when the hydraulic controls are operated

and possibly allow unwanted cylinder movement when

those controls are not being operated.

Attachment coupler handles must always be rotated

to lOCK POSiTiON to prevent coupler latch from

disengaging and attachment from falling off.

WArNiNG

WArNiNG

10

11

INSTRUCTIONS

INSTRUCTIONS

(continued)

TINE OR SCRAP GRAPPLE BUCKET INSTALLATION

Attachment to Prime Mover

TINE OR SCRAP GRAPPLE BUCKET INSTALLATION

Attachment to Prime Mover - (continued)

3. Enter the prime mover. Fasten seatbelt, start engine. Disengage the parking brake.

4. Follow the attaching procedure in the prime mover owner's manual. Align the attachment mechanism with the

mounting on the grapple bucket, attach to the prime mover or loader.

5. Engage the parking brake and shut down the prime mover. Be sure to relieve pressure to the auxiliary hydraulic

lines.

6. Unfasten safety restraints and exit the prime mover.

7. Make sure the hydraulic couplers are clean. Connect the hydraulic lines to the prime mover. Twist the collar of the quick

couplers one-quarter turn to secure hydraulic connections. If attachment unit is being installed on a tractor loader,

purchase proper couplers and hoses as required and attach to the loader as per the manufacturers instructions.

8. Engage the latching mechanism to secure attachment to loader. The lockpins must be completely extended and

secured into the retaining slots provided on the attachment. Figure 3.

9. Re-enter the primer mover. Fasten seatbelt and re-start engine.

10.Carefully raise the loader and cycle the rollback/tilt cylinders to check clearances and to ensure that the attachment

is securely mounted.

11.Cycle the grapple clamp hydraulic cylinders several times full stroke to work the air out of the cylinders.

NOTICE: When shipped, the hydraulic cylinder(s) on this product contained air. Failure to remove all the air

from the hydraulic cylinder(s) can cause uneven, jerky cylinder movement when the hydraulic con-

trols are operated and possibly allow unwanted cylinder movement when those controls are not

being operated.

1. If possible, find a level solid location to place the attachment. This makes it easier to disconnect and to re-connect

later on.

2. Lower the attachment to the ground.

3. Engage the parking brake and shut down the prime mover. Be sure to relieve pressure to the auxiliary hydraulic

lines.

4. Unfasten safety restraints and exit prime mover.

5. Disconnect the attachment hydraulic lines from the prime mover. Connect quick couplers together to keep clean.

6. Disengage attachment-locking mechanism (mechanical type).

7. Enter prime mover, fasten safety restraints and start the prime mover.

8. Disengage attachment-locking mechanism (hydraulic type).

9. Disengage the parking brake, and back away from the attachment.

1. Position the attachment on a level surface.

2. The quick attach coupler handles should be in the unlocked position with lock pins retracted, Figure 2.

Figure 2. Quick Attach Coupler Handles - Unlocked

Improper attachment of the Tine or Scrap Grapple Bucket could result in injury or death. Do

not operate this product until you have positive indication that the attachment is securely

mounted.

WARNING!

Serious injury or death may result from disengaging the attachment when the attachment

is in an unstable position or carrying a load. Place the attachment in a stable position

before disengaging.

WARNING!

Hoses for the attachment must be disconnected before the quick attach is disengaged.

Pulling the attachment with the hoses could result in damage to the prime mover or the

attachment.

CAUTION

Attachment coupler handles must always be

rotated to LOCK POSITION to prevent coupler

latch from disengaging and attachment from

falling off.

WARNING!

Figure 3. Attachment Coupler Handles - Locked

REMOVING THE TINE OR SCRAP GRAPPLE BUCKET

10

11

INSTRUCTIONS

INSTRUCTIONS

(continued)

TINE OR SCRAP GRAPPLE BUCKET INSTALLATION

Attachment to Prime Mover

TINE OR SCRAP GRAPPLE BUCKET INSTALLATION

Attachment to Prime Mover - (continued)

3. Enter the prime mover. Fasten seatbelt, start engine. Disengage the parking brake.

4. Follow the attaching procedure in the prime mover owner's manual. Align the attachment mechanism with the

mounting on the grapple bucket, attach to the prime mover or loader.

5. Engage the parking brake and shut down the prime mover. Be sure to relieve pressure to the auxiliary hydraulic

lines.

6. Unfasten safety restraints and exit the prime mover.

7. Make sure the hydraulic couplers are clean. Connect the hydraulic lines to the prime mover. Twist the collar of the quick

couplers one-quarter turn to secure hydraulic connections. If attachment unit is being installed on a tractor loader,

purchase proper couplers and hoses as required and attach to the loader as per the manufacturers instructions.

8. Engage the latching mechanism to secure attachment to loader. The lockpins must be completely extended and

secured into the retaining slots provided on the attachment. Figure 3.

9. Re-enter the primer mover. Fasten seatbelt and re-start engine.

10.Carefully raise the loader and cycle the rollback/tilt cylinders to check clearances and to ensure that the attachment

is securely mounted.

11.Cycle the grapple clamp hydraulic cylinders several times full stroke to work the air out of the cylinders.

NOTICE: When shipped, the hydraulic cylinder(s) on this product contained air. Failure to remove all the air

from the hydraulic cylinder(s) can cause uneven, jerky cylinder movement when the hydraulic con-

trols are operated and possibly allow unwanted cylinder movement when those controls are not

being operated.

1. If possible, find a level solid location to place the attachment. This makes it easier to disconnect and to re-connect

later on.

2. Lower the attachment to the ground.

3. Engage the parking brake and shut down the prime mover. Be sure to relieve pressure to the auxiliary hydraulic

lines.

4. Unfasten safety restraints and exit prime mover.

5. Disconnect the attachment hydraulic lines from the prime mover. Connect quick couplers together to keep clean.

6. Disengage attachment-locking mechanism (mechanical type).

7. Enter prime mover, fasten safety restraints and start the prime mover.

8. Disengage attachment-locking mechanism (hydraulic type).

9. Disengage the parking brake, and back away from the attachment.

1. Position the attachment on a level surface.

2. The quick attach coupler handles should be in the unlocked position with lock pins retracted, Figure 2.

Figure 2. Quick Attach Coupler Handles - Unlocked

Improper attachment of the Tine or Scrap Grapple Bucket could result in injury or death. Do

not operate this product until you have positive indication that the attachment is securely

mounted.

WARNING!

Serious injury or death may result from disengaging the attachment when the attachment

is in an unstable position or carrying a load. Place the attachment in a stable position

before disengaging.

WARNING!

Hoses for the attachment must be disconnected before the quick attach is disengaged.

Pulling the attachment with the hoses could result in damage to the prime mover or the

attachment.

CAUTION

Attachment coupler handles must always be

rotated to LOCK POSITION to prevent coupler

latch from disengaging and attachment from

falling off.

WARNING!

Figure 3. Attachment Coupler Handles - Locked

REMOVING THE TINE OR SCRAP GRAPPLE BUCKET