Cub Cadet 8354 User Manual

Page 51

51

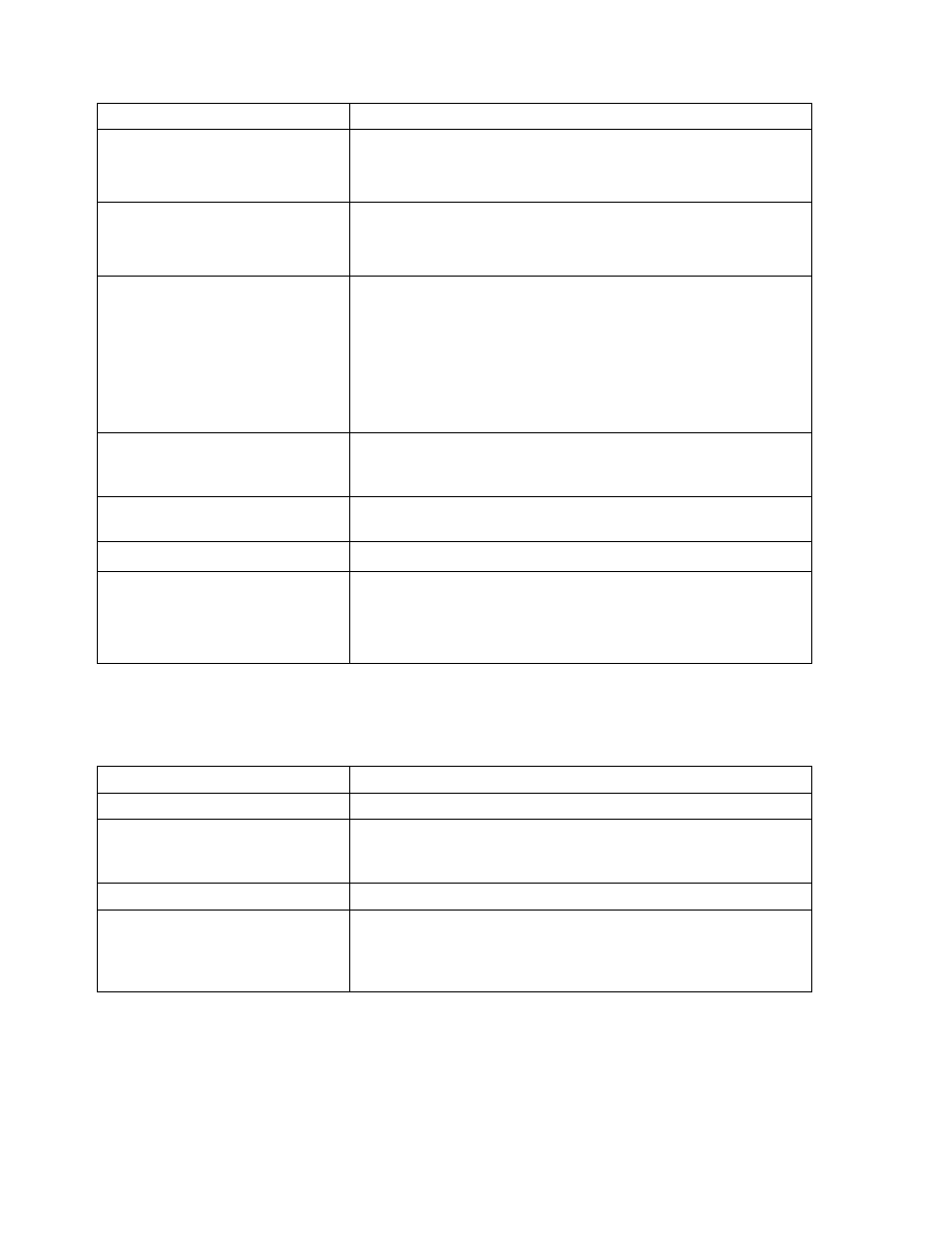

When Output Is Insufficient

When Color of Exhaust Is Especially Bad

See your Cub Cadet dealer.

Cause

Countermeasures

Carbon build-up around orifice of

nozzle piece

- Clean orifice and needle valve, while being very careful not to damage

the nozzle orifice.

- Check nozzle. If defective, replace with new parts.

Compression is insufficient

- Bad valve and excessive wear of rings, pistons, and liners cause

insufficient compression. Replace with new parts.

- Grind valves.

Overheating of moving parts

- Check engine lubrication system.

- Check to see if lube oil filter is working properly.

- Filter screens or elements deposited with impurities would cause poor

lubrication. Clean Screens.

- Check to see if bearing clearances ar within factory specifications.

- Check engine timing. Adjust timing to 18° before top dead center.

Valve out of adjustment

- Adjust to proper valve clearance:

Intake — 0.0098 in. (0.25mm)

Exhaust — 0.0118 in. (0.3mm)

Air cleaner is dirty

- Clean the element and dust cup weekly, and replace element after

every 100 hours of operation.

Fuel injection pressure is wrong

- Adjust to proper pressure of 2.000 psi (140 kgf/cm

2

- 13.7 KPa).

Injection pump wear

- Do not use poor quality fuel because it will cause wear of the the pump.

Only use No. 2 diesel fuel.

- Check the fuel injection pump element and delivery valve assembly and

replace as necessary.

Cause

Countermeasures

Fuel governing device is bad

- Contact your dealer for repairs.

Fuel is of extremely poor quality

- Select good quality fuel:

Above 14°F (-10°C) — No. 2 Diesel fuel

Below 14°F (-10°C) — No. 1 Diesel fuel

Nozzle is bad

- If necessary, replace with new nozzle.

Combustion is incomplete

- Cause is poor atomization, improper injection timing, etc. because of

trouble in the injection system, or because of poor valve adjustment,

compression leakage, poor compression, etc. Check for the cause and

repair.