Cub Cadet 8354 User Manual

Page 37

37

•

Use No. 2 diesel fuel. Use No. 1 diesel fuel if the

temperature is below 15° F (-10°C).

•

The fuel tank capacity is approximately 10.6 gal.

Do not overfill.

Bleeding the Fuel System

WARNING: Do not bleed the fuel system

when the engine is hot.

Air must be bled from the fuel system when the fuel

filter or fuel lines are removed; the fuel tank is

completely emptied; or the tractor has not been used

for a long period of time.

•

Fill the fuel tank with No. 2 diesel fuel and make

certain the shut-off valve on the fuel filter is open.

•

Loosen the air vent cock on the injection pump

two or three turns by hand, then start to turn the

engine over. See Figure 52.

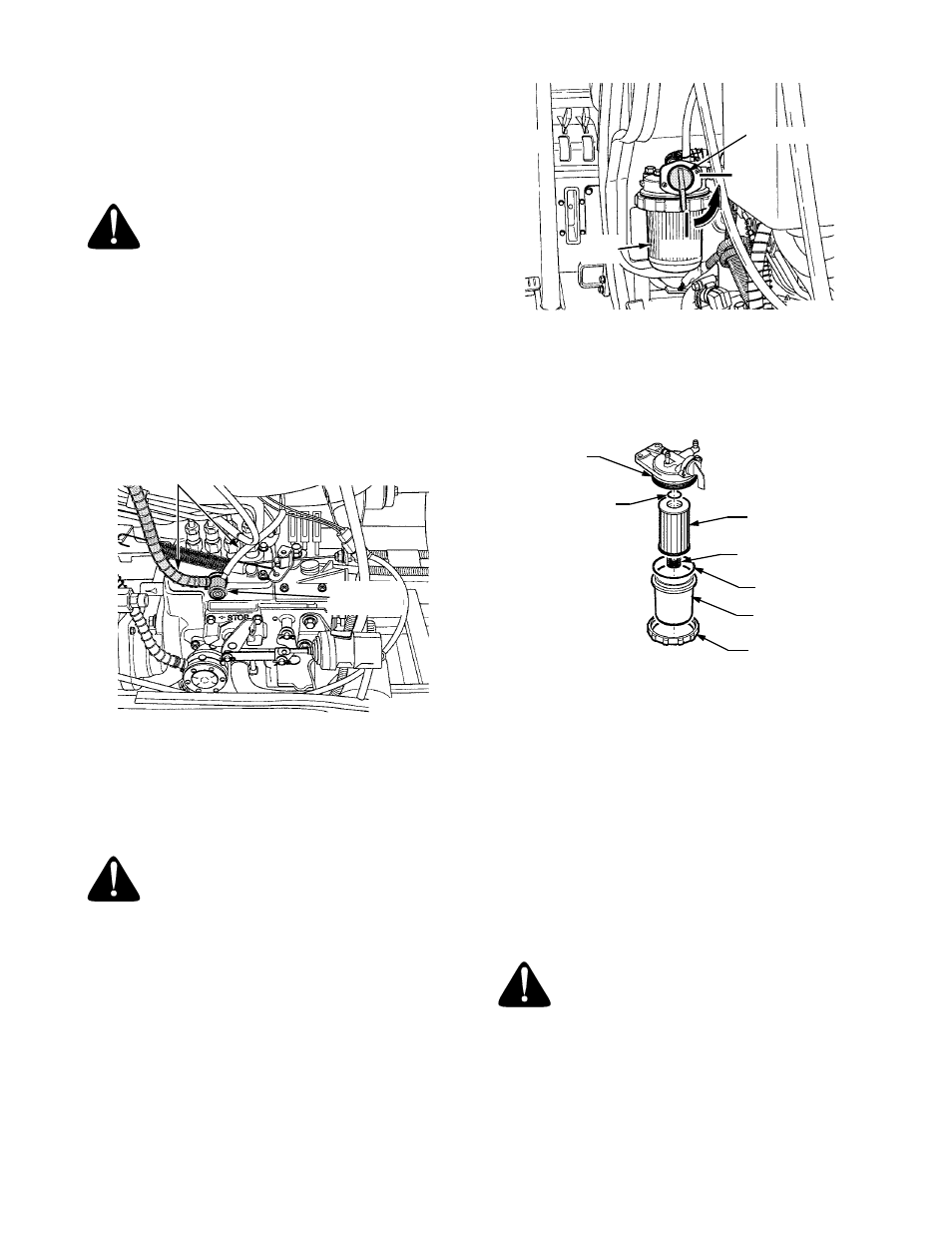

Figure 52

•

When there are no more air bubbles in the fuel

line, tighten the air vent cock.

Servicing the Fuel Filter

WARNING: When servicing the fuel fil-

ter element, take all precautions to

prevent dust or dirt from entering the

fuel system. Contaminants will cause

premature wear and/or malfunction of

the injection pump and injection

nozzles.

The fuel filter should be cleaned after every 100

hours of operation, and replaced after every 400

hours.

•

Make certain the area is free of dust and dirt.

•

Close the shut-off valve on the fuel filter. See

Figure 53.

Figure 53

•

Unscrew the retaining ring and remove the ring

and fuel filter bowl from the filter. Use care not to

lose the O-ring and spring. See Figure 54.

Figure 54

•

Flush the bowl out with clean diesel fuel.

•

Remove the element and either dip it into a con-

tainer of clean diesel fuel to clean it, or replace it

with a new element.

•

Install the new, or cleaned, element onto the fil-

ter body.

•

Install the filter bowl and retaining ring over the

element, and tighten the retaining ring to secure.

•

Bleed the air from the fuel system using the air vent

cock on the injection pump. Refer to Figure 52.

Checking the Fuel Lines

WARNING: The fuel line hoses are

subject to wear and natural aging. A

leaking fuel line may allow fuel to come

into contact with sources of ignition, and

could cause a fire.

The condition of the fuel line hoses and clamps

should be checked every 100 hours or six months

(whichever occurs first), and they should be replaced

every two years. Refer to Figure 52.

Fuel Line

Turn Air

Vent Cock

Close

Shut-off Valve

Open

Fuel

Filter

Retaining Ring

Bowl

O-ring

Spring

Filter Element

O-ring

Filter Body

(DD-84612-4316-0)