4wd movement board test, Tb 1, Tb 2 – Dynojet 424 Linx: 4WD Dyno Air and Wiring Schematic User Manual

Page 2

D

YN

O

JE

T

R

E

SE

A

R

C

H

,

IN

C

0

3

/1

6

/0

0

TB

2

RA

IL

OU

T

IN

BR

K 2

BR

K 1

BRK IN +12V

C

O

M

PRES

----

G

N

D

IN OUT

SW

TB

1

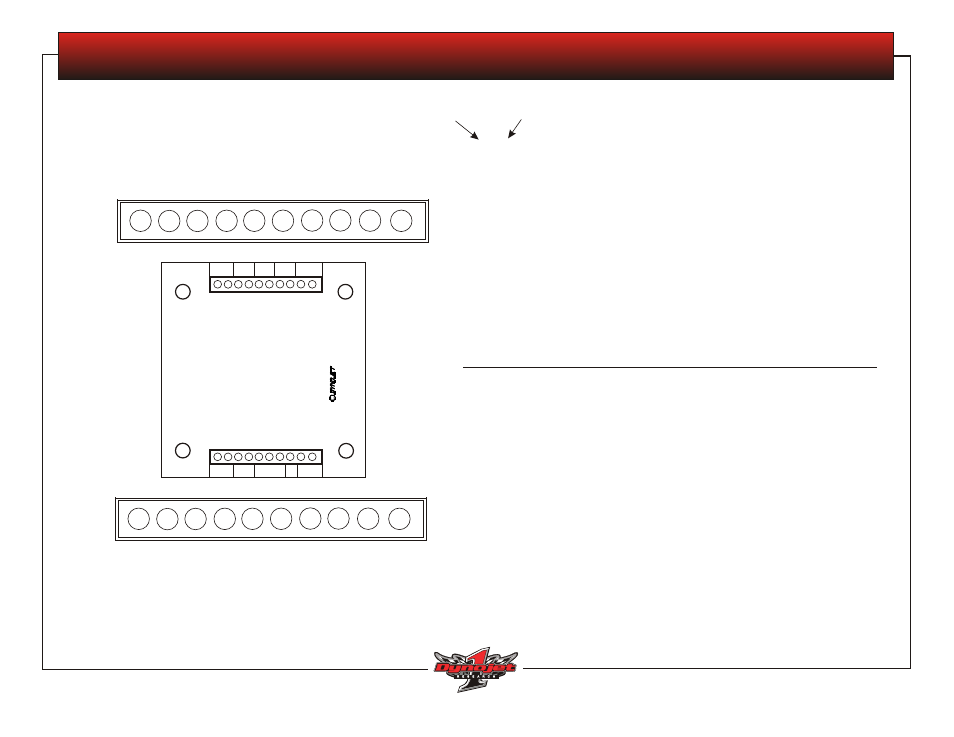

4WD Movement

65412001

Use a multi-meter to read each terminal and determine the voltage that

should be present as listed on this sheet.

The red probe is always placed on the first number.

TB2: Top Row of Terminals on PCB

Reading Left to Right

TB1: Bottom Row of Terminals on PCB

Reading Left to Right

1—2

brake signal from Breakout board

brake off

+12 VDC

brake on

0 VDC

3—4

12 VDC in from P/S

5—4

when brake is applied, reads 12 VDC

6—4

with brake applied, with the remote switch pressed to IN, reads 12 VDC

7—4

with brake applied, with the remote switch pressed to OUT, reads 12 VDC

8—

not wired

For this test, you will check for continuity:

9—10 air pressure switch: sufficient air pressure equals continuity, insufficient air

pressure equals no continuity

10—9 brake signal to cable

brake off

+12 VDC

brake on

0 VDC

8—7

brake signal to solenoid

brake off

+12 VDC

brake on

0 VDC

6—5

11.57 VDC when IN switch on remote is pushed

4—3

11.57 VDC when OUT switch on remote is pushed

2—1

10.68 VDC when either IN/OUT switch is pushed on remote

T

B

1

1

2

3

4

5

6

7

8

9

10

TB

2

10

9

8

7

6

5

4

3

2

1

red probe

on first

number

black

probe

For assistance, call Dynojet Technical Support at 1-800-992-3525, visit www.dynojet.com, or write to Dynojet at 2191 Mendenhall Drive, North Las Vegas, NV 89031.

98225108 • Version 1 • Page 2 of 2

© Copyright 2004 Dynojet Research, Inc. All Rights Reserved. 02/2004SD

4WD MOVEMENT BOARD TEST