Installing the air brake assembly – Dynojet 250iP: Air Brake and EEC Kit User Manual

Page 14

Air Brake and EEC Kit Installation Guide for 200i/250i and 200iP/250iP Motorcycle Dynamometers

A I R B R A K E A N D E E C K I T

Air Brake

10

I

NSTALLING

THE

A

IR

B

RAKE

A

SSEMBLY

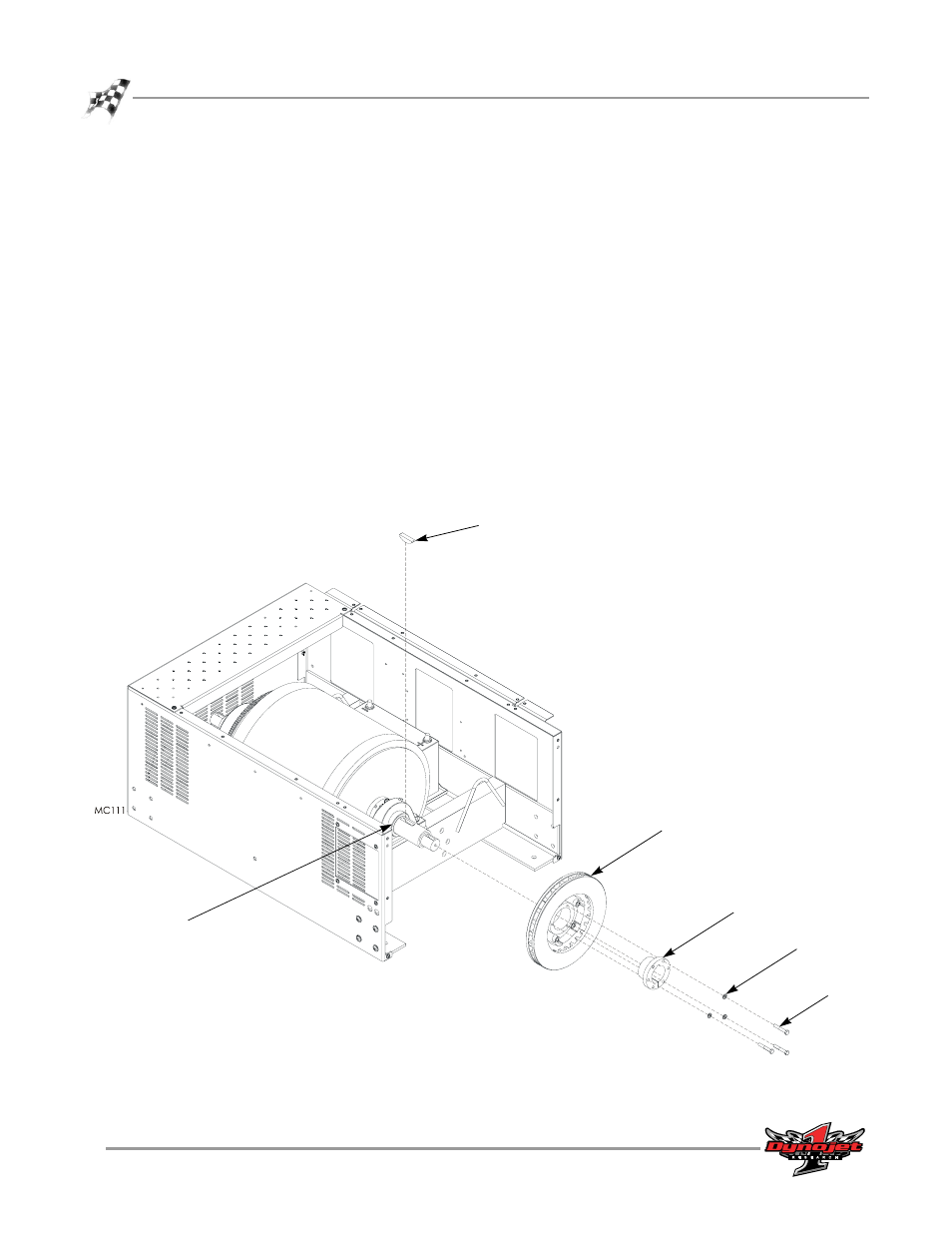

The following instructions are for both the model 200i/250i above ground and

200iP/250iP pit motorcycle dynamometers. If you are not installing the air brake skip

this section and refer to “EEC Finger Guards—200i/250i” on page 20, “EEC Finger

Guards—200iP/250iP” on page 23, and “Door Safety Switch” on page 29.

1

Turn off the dyno and disconnect the AC power cord from its power source.

2

Insert the woodruff key into the dyno shaft.

3

Slide the brake rotor with taper lock onto the shaft and align it, so that the taper

lock touches the bearing lock collar on the dyno shaft.

4

Set up a dial indicator on the disc braking surface to measure the run-out. The

maximum allowable run-out is +/- 0.005 inches.

5

Tighten the three bolts in a clockwise rotation to help minimize the run out,

torquing to 15 foot-pounds.

Note: If necessary, readjust the taper lock and brake rotor to ensure the run-out is

less than +/- 0.005 inches.

Note: For clarity, only the drum module is shown.

Figure 8: Securing the Brake Rotor

bearing lock

collar

bolt

washer

taper lock

brake rotor

woodruff key