Wiring diagram, Wiring instructions, Installation and mounting instructions: cont – Code 3 SuperVisor with Torus User Manual

Page 3: Warning! led fusing considerations, Warning

PASSENGER

SIDE

DRIVER

SIDE

LT BLUE

PURPLE

WHITE

RED

ORANGE

GREEN/WHT

RED/WHITE

PINK

BROWN

BLACK----------NEGATIVE GROUND

BLUE/WHT---------NOT USED

GREEN------------NOT USED

YELLOW-----------NOT USED

FUSE SIZE CALCULATION:

USE .5 AMP FOR EACH LED HEAD

WIRING DIAGRAM

BROWN/WHT

5

4

Larger wires and tight connections will provide longer service life for components. For high current wires it

is highly recommended that terminal blocks or soldered connections be used with shrink tubing to protect

the connections. Do not use insulation displacement connectors (e.g. 3M

®

Scotchlock type connectors).

Route wiring using grommets and sealant when passing through compartment walls. Minimize the

number of splices to reduce voltage drop. High ambient temperatures (e.g. under hood) will significantly

reduce the current carrying capacity of wires, fuses, and circuit breakers. Use "SXL" type wire in engine

compartment. All wiring should conform to the minimum wire size and other recommendations of the

manufacturer and be protected from moving parts and hot surfaces. Looms, grommets, cable ties, and

similar installation hardware should be used to anchor and protect all wiring. Fuses or circuit breakers

should be located as close to the power takeoff points as possible and properly sized to protect the wiring

and devices. Particular attention should be paid to the location and method of making electrical connections

and splices to protect these points from corrosion and loss of conductivity. Ground terminations should

only be made to substantial chassis components, preferably directly to the vehicle battery. The user should

install a fuse sized to approximately 125% of the maximum Amp capacity in the supply line to protect

against short circuits. For example, a 30 Amp fuse should carry a maximum of 24 Amps. DO NOT USE

1/4" DIAMETER GLASS FUSES AS THEY ARE NOT SUITABLE FOR CONTINUOUS DUTY IN SIZES

ABOVE 15 AMPS. Circuit breakers are very sensitive to high temperatures and will "false trip" when

mounted in hot environments or operated close to their capacity.

wARNINg!

LED Fusing Considerations

Although the average current draw per module is very low, due to the type of circuit used to power each module, the instan-

taneous peak current to a module can be significantly higher during low voltage conditions. To avoid prematurely blowing

ATO style fuses or tripping breakers it is recommended the following rule-of-thumb be used to size fuses or breakers. This is

especially important in lightbars with many LED modules running off a single fused source.

Minimum fuse size calculation: (See wiring Diagram page 5)

For LED 12 volt electrical current only

.5 X (number of 3 LED modules being fused) = Total Electrical Current at 12.8 VDC

This Product contains high intensity LED devices. To prevent eye damage,

DO NOT stare into light beam at close range.

wARNINg!

wiring Instructions

Finish routing the cable as desired. It is advisable to leave an extra loop of cable when installing the light bar to allow for future

changes or reinstallations. Connect the black lead to a solid frame ground (earth), preferably the (-) or ground (earth) side of the

battery, and the power wire to the +12V terminal of the battery. Connect the remaining wires as shown on page 5.

Caution: Drilling into the housing of the light bar could damage wiring or other internal components.

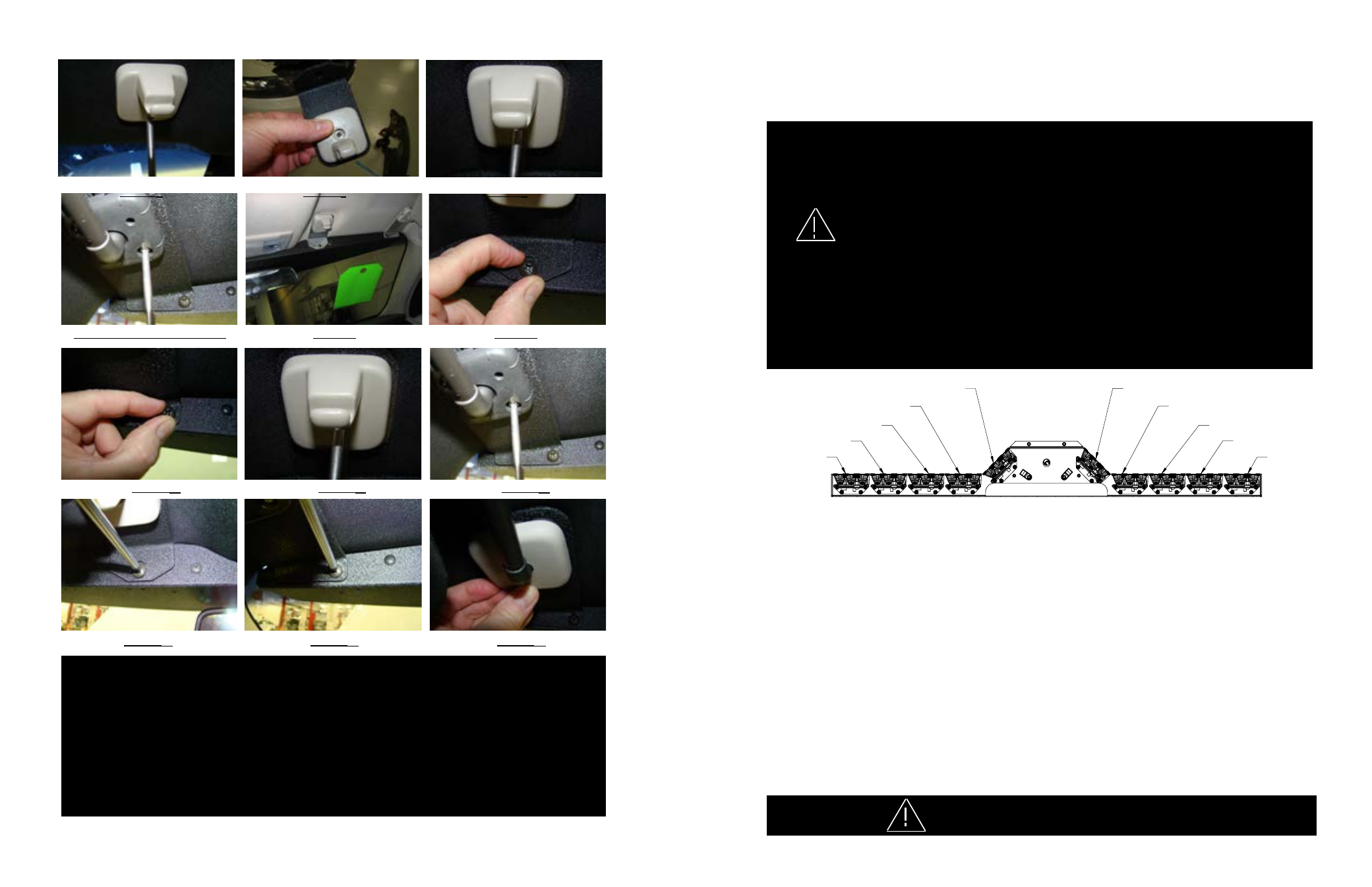

FIgURE

10

FIgURE

11

FIgURE

12

FIgURE

13

FIgURE

14

FIgURE

15

FIgURE

7-DRIVER SIDE SHOwN

FIgURE

8

FIgURE

9

Installation and Mounting Instructions: Cont.

wARNINg: This unit must be mounted within the interior passenger compartment of the vehicle only. It is not intended

for use in exterior applications. All devices should be mounted in accordance with the manufacturer’s instructions

and securely fastened to vehicle elements of sufficient strength to withstand the forces applied to the device.

Driver and/or passenger air bags (SRS) will affect the way equipment should be mounted. This device should be

mounted by permanent installation and within the zones specified by the vehicle manufacturer, if any. Any device

mounted in the deployment area of an air bag will damage or reduce the effectiveness of the air bag and may damage

or dislodge the device. Installer must be sure that this device, its mounting hardware and electrical supply wiring does

not interfere with the air bag or the SRS wiring or sensors. Mounting the unit inside the vehicle by a method other

than permanent installation is not recommended as unit may become dislodged during swerving, sudden braking or

collision. Failure to follow instructions can result in personal injury.

FIgURE

4

FIgURE

5

FIgURE

6