Maintenance, Electrical connections, Warning – Code 3 LED Triple Stack User Manual

Page 3

3

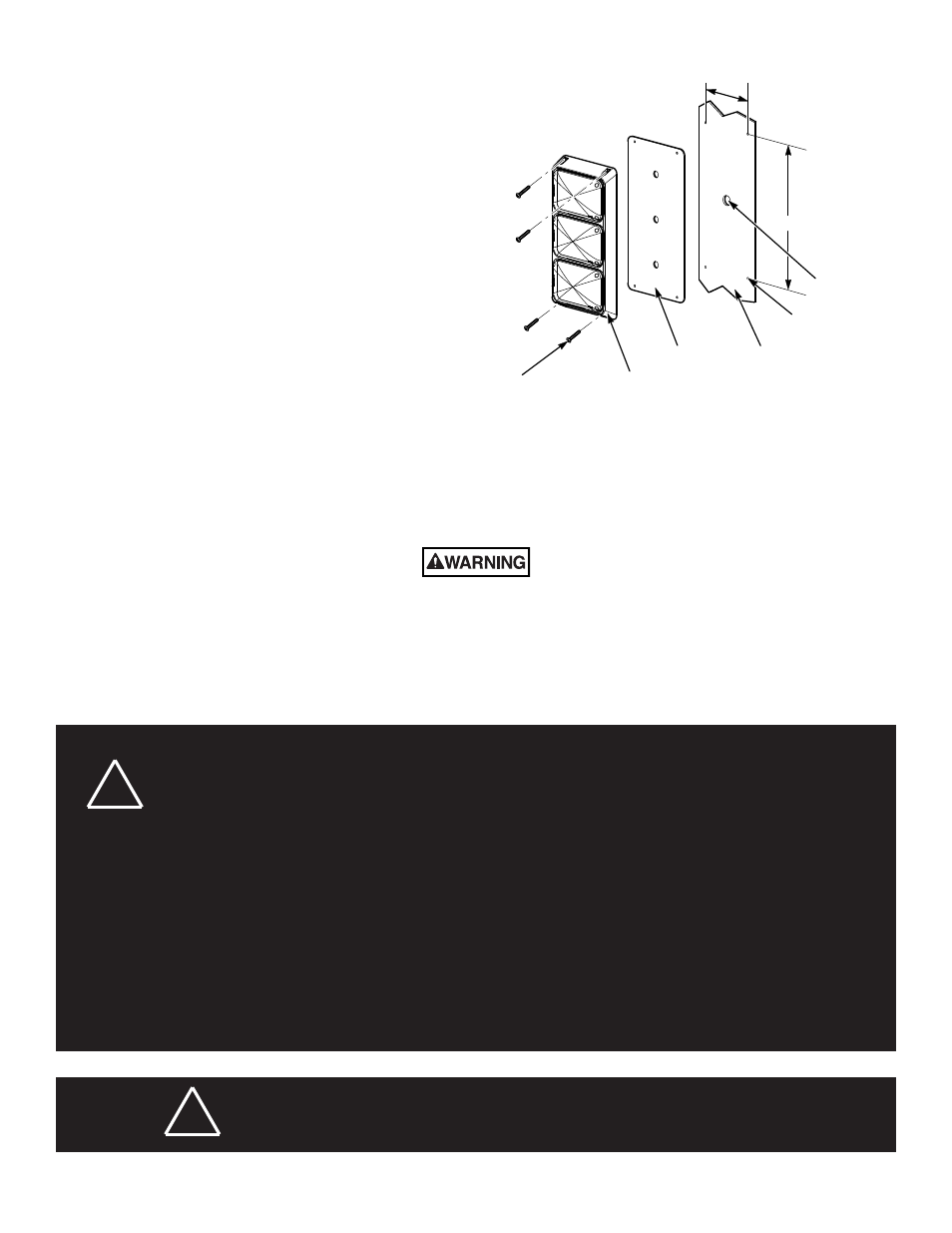

CABLE ROUTING

HOLE

5.75"

14.38"

Ø9/64" (4 PLACES)

#10 X 3/4"

SCREW(4)

QL64Z3V

MOUNTING

GASKET

VEHICLE

BODY

Using 18-gauge (minimum) wire, connect the red (+) lead to the positive

power source terminal for BRAKE mode, and the white (+) lead to a

different positive power source terminal for TAIL mode. The black (–) lead

should be connected to the negative power source terminal.

Two 12-inch-long lead wires are supplied for making electrical connections

to the turn arrow and reverse light assemblies.

Using 18-gauge (minimum) wire, connect the red (+) lead to the positive

power source terminal and the black (–) lead to the negative power source

terminal.

Figure 1.

MAINTENANCE

Crazing (cracking) of the lenses will cause reduced effectiveness of the light. Do not use cleaning agents (which will cause craz-

ing) such as strong detergents, solvents, or petroleum products. If crazing of the lenses does occur, the reliability of the light for

emergency signalling purposes may be reduced until the lenses are replaced.

To clean the plastic lenses, use a mild soap and a soft cloth. Remove fine scratches and haze with a non-abrasive, high quality, one-step, automotive

paste cleaner/wax and a soft cloth.

!

Larger wires and tight connections will provide longer service life for components. Do not use insulation displacement connectors

(e.g., 3M® Scotchlock type connectors). Route wiring using grommets and sealant when passing through compartment walls.

Minimize the number of splices to reduce voltage drop. High ambient temperatures (e.g., under-hood) will significantly reduce

the current carrying capacity of wires, fuses, and circuit breakers. Use “SXL” type wire in engine compartment. All wiring should

conform to the minimum wire size and other recommendations of the manufacturer and be protected from moving parts and hot

surfaces. Looms, grommets, cable ties, and similar installation hardware should be used to anchor and protect all wiring.

Particular attention should be paid to the location and method of making electrical connections and splices to protect these

points from corrosion and loss of conductivity. Ground terminations should only be made to substantial chassis components,

preferably directly to the vehicle battery.

The user should install a fuse sized to approximately 125 percent of the maximum amperage capacity in the supply line and

each switched circuit to protect against short circuits. For example, a 30-ampere fuse should carry a maximum of 24 amperes.

DO NOT USE 1/4” DIAMETER GLASS FUSES AS THEY ARE NOT SUITABLE FOR CONTINUOUS DUTY IN SIZES ABOVE

15 amperes. Circuit breakers are very sensitive to high temperatures and will “false trip” when mounted in hot environments or

operated close to their capacity. Fuses or circuit breakers should be located as close to the power takeoff points as possible

and properly sized to protect the wiring and devices.

WARNING

ELECTRICAL CONNECTIONS

The Triple Stack warning light assembly is designed to operate on 12 Vdc.

Three 12-inch long lead wires are supplied for making electrical

connections to the brake/tail light assembly.

WARNING

!

Any electronic device may create or be affected by electromagnetic interference. After installation of any electronic

device, operate all equipment simultaneously to insure that operation is free of interference.