Permanent - resilient mounting – Code 3 550 Series Beacon User Manual

Page 4

4

A Code 3 supplied magnetic mounting kit is available for field retrofit, if required. The lens and rotator

assembly must be removed so that the mounting hole is accessible for drilling. Use a #11 (.191") bit to

drill the mounting hole from inside the base. Drop the nylock nut into place. Assemble washer, screw

and magnet as shown in Figure 1 and attach to base.

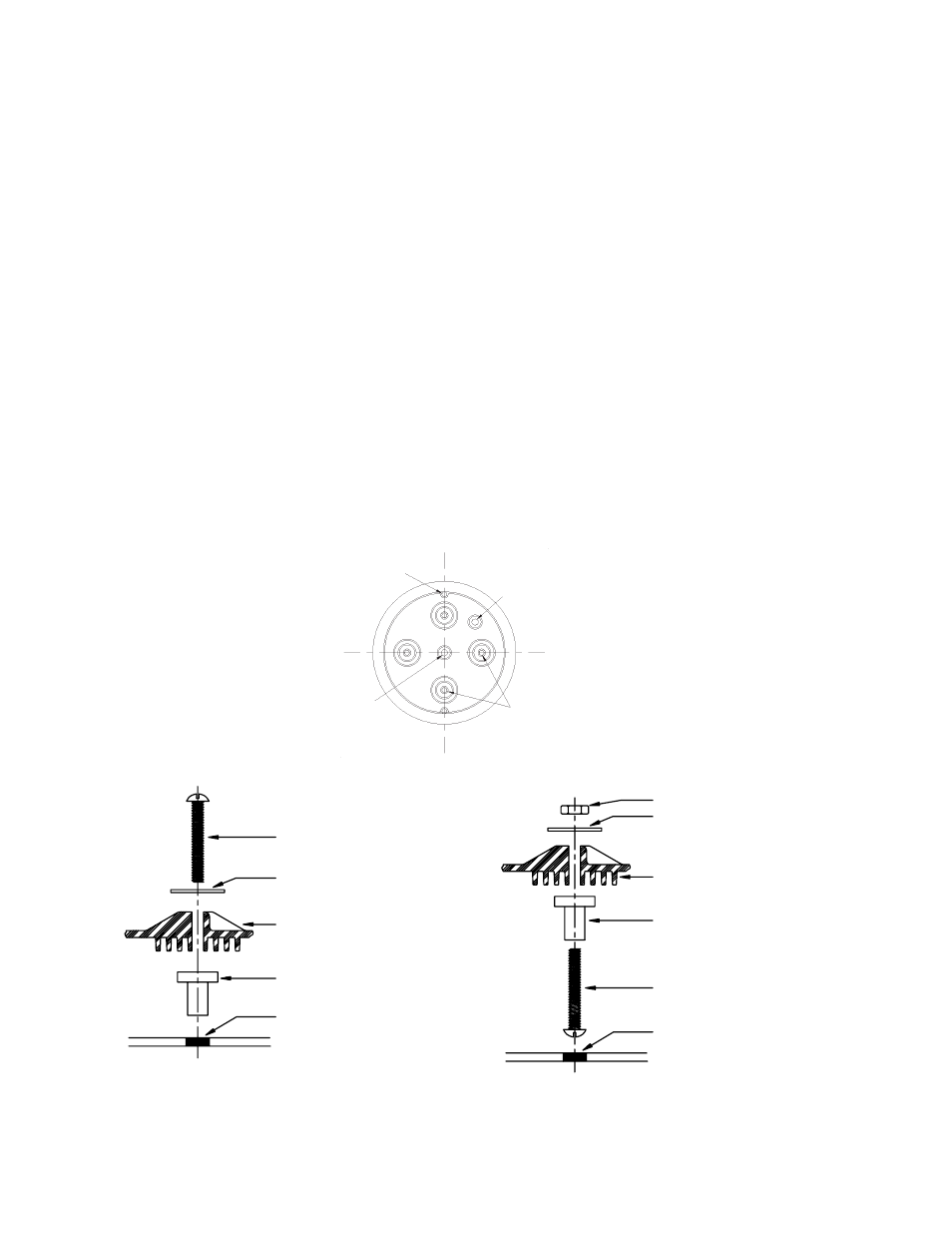

Permanent - Resilient Mounting

Locate the Model 550

TM

Beacon on the highest possible level surface on the vehicle for the maximum

warning signal. CAUTION! When drilling into any vehicle surface, make sure that each side is free from

anything that could be damaged (i.e. electrical wires, fuel lines or vehicle upholstery). Remove the lens

and use the base as a template to mark the wiring and four mounting holes onto the area you wish to

mount the beacon. You must first use a #11 (.191") drill bit and drill out the four mounting holes, see

Figure 2. The two mounting holes closer to the edge of the base may be used when trying to fit an

existing hole pattern. Then, using the base as a template and a

3

/

8

" drill bit, drill wiring and mounting

holes. After drilling the holes, remove any burrs and install a rubber grommet before passing wires

through the wiring hole, apply sealant around wires to seal hole to prevent leakage.

For permanent mounting, use user supplied hardware. For resilient mounting, use a factory available

Resilient Mounting Kit. See Figure 3 for mounting positions. The correctly installed rubber-threaded

insert is a watertight and shock-resistant mount which will increase the effectiveness and long life of the

product. Do not overtighten the screws! In applications where the screws protrude into the passenger

compartment, the screw can be reversed to minimize the risk of personal injury. See Figure 4. In this

configuration do not tighten the nut until all hardware is positioned properly.

FIGURE 2

Drain

& Vent

Standard

Mounting

Holes

Edge

Mounting

Holes

Aux.

Drain / Vent

Mounting Boss on

Beacon Base

#10-32 x 1

1

/

2

" Screw

#10 Screw Washer

3

/

8

" Rubber Threaded Insert

3

/

8

" Dia. Hole

#10 Screw Washer

#10-32 Nylock Nut

Mounting Boss on

Beacon Base

3

/

8

" Rubber Threaded Insert

#10-32 x 1

1

/

2

" Screw

3

/

8

" Dia. Hole

FIGURE 4

FIGURE 3