O.o.o.o, Calibration procedures, Ooo.o o – CDI Torque COMPUTORQ II Electronic Torque Wrench User Manual

Page 8: Ooo.o 2

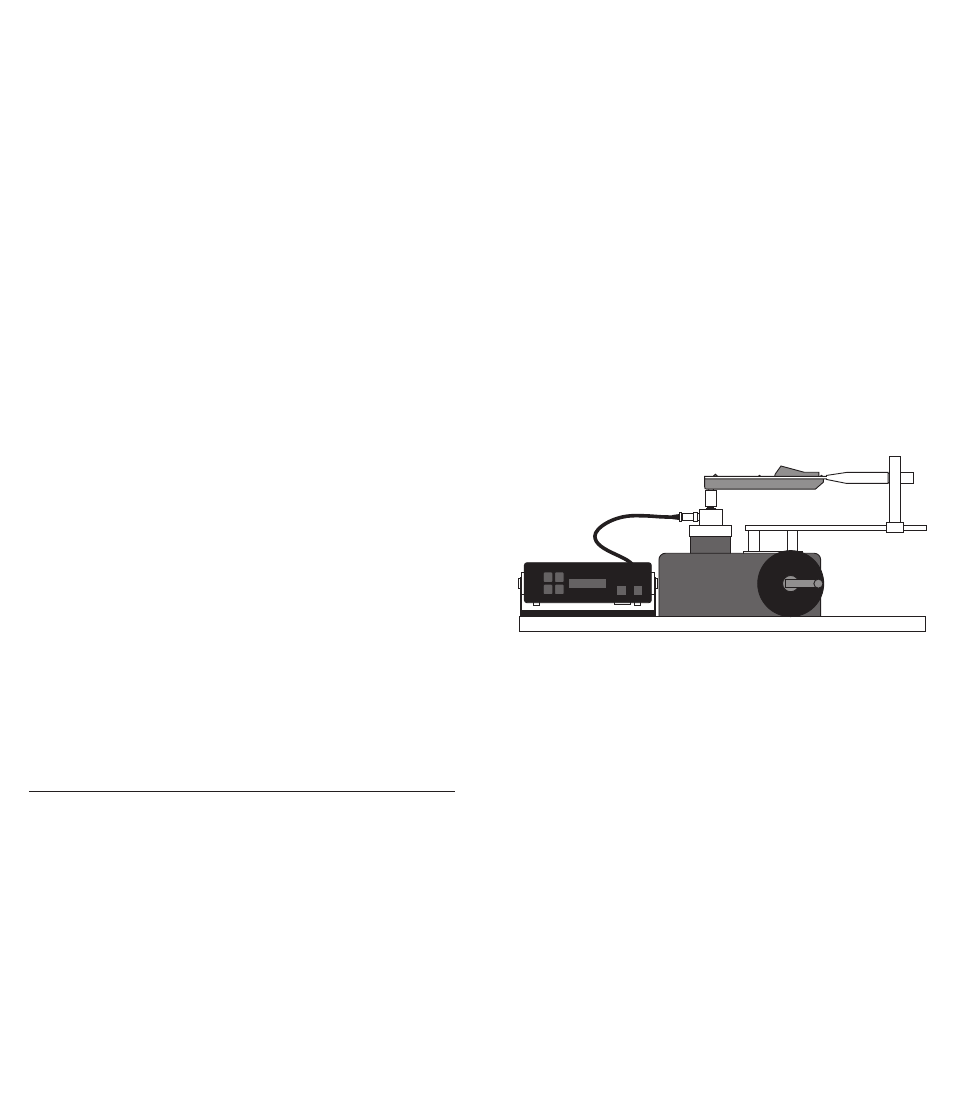

cALIbRATION PROcEdURES

Due to the accuracy and the sensitivity of the

Computorq II electronic torque wrench, a mechanical

torque loader with a torque display (preferably

electronic) must be used for input torque. The loader is

necessary because the human hand cannot “push” or

“pull” on the wrench with enough stability for the torque

input to be an accurate value.

The calibration procedure must be done in both

directions (CW and CCW).

Please consider the following calibration precautions:

• Make sure the Computorq II is level (or horizontal

while in the loader. If not, side loading may affect the

true readings.

• Make sure the “reaction point” is in the center of the

grip or handle.

• Make sure the least amount of sockets and adapters

are used when mating to the calibration equipment.

• Check all sockets and adapters for “excessive play.”

This could result in false loads being applied and

shown on the display.

• Make sure the wrench is in the proper torque

engineering units prior to calibrating.

• Make sure the wrench mode of operation is in

“

TRACK.” Refer to the “OPERATING INSTRUCTIONS”

section for proper setup.

* Accuracy

+/-1% From 20-100% of scale.

+/-1%, plus 5 increments, from 10-20% of scale.

SPECIFICATIONS

Product

Torque

Length Wt.

Code

Drive Range

Incr.

In.

Lbs.

501CI-II

1/4” 5-50 in.lb.

.01 in.lb. 13.5

1.5

2502CI-II 3⁄8” 25-250 in.lb.

.1 in.lb.

14.9

2.0

502CF-II

3⁄8” 5-50 ft.lbs.

.01 in.lb. 14.9

2.0

2503CF-II 1⁄2” 25-250 ft. lbs.

.1 in.lb.

21.5

3.2

6004CF-II 3⁄4” 60-600 ft.lbs.

.2 in.lb.

46.5

9.5

10005CF-II 1”

100-1000 ft.lb.

.1 ft.lb.

74.0

19.0

cALIbRATION PROcEdURES

Wrenches may be set up in 7 different torque

engineering units: ft. lb., in. lb., in. oz., nm, dNm,

mkg or cmkg. Refer to “TO CHANGE UNIT OF TORQUE

MEASURE” in the “OPERATING PROCDURES”.

Factory set parameters: Transmission data rate is 1200

baud; Communication protocol is RS 232 ASCII, 8

data bit, no parity. Other options are available, please

consult factory for additional information.

Please Note: Computorq II has an exclusive feature

— when using extensions or adapters, Computorq II’s

electronics can automatically compensate for these

extra lengths. Refer to the “PROCEDURES FOR USING

ADAPTERS” section.

1

CLEAR

ZERO

dNm cmkg in-oz in-lb ft-lb

LO BAT

TRACK

PEAK

RECALL

SETUP

AUTO POWER OFF

STORE

SEND

2

3

4

COMPUTORQ II

OVER

o.o.o.o

000

000

6.00’

6.00’

6.00’

1

o.o.o.o

1

CLEAR

ZERO

STORE

SEND

2

RECALL

SETUP

3

4

STORE

SEND

2

RECALL

SETUP

3

4

TRACK

ooo.o

o

TRACK

2.ooo

TRACK

ooo.o

2

2”

BATTERY

BATTERY

OFF ON

0 0 0 1

LINE FEED

CARRIAGE

RETURN

UNITS

BLANK

VALUE

SIGN

BLANK

SEQUENCE #

1 2 3 , 4 5

I N - L B

CR LF

+

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

V

INSTRUCTIONS LEGEND

LIGHT ON

BUZZER SOUNDS

INPUTTING THE LENGTH OF THE ADAPTOR

ACCEPTED

GO BACK TO MAIN MENU

CENTER OF SQUARE DRIVE TO

CENTER OF THE OPEN END.

BOX END OR FLARE NUT DRIVES

PRESS

PRESS + HOLD

UNITL

BUZZER SOUNDS

COMPUTORQ II shown being Calibrated

on a Mechanical Loader.