CDI Torque COMPUTORQ II Electronic Torque Wrench User Manual

Page 4

OPERATING INSTRUcTIONS

•

TO SET A TARGET TORqUE VALUE:

1. Press Button #4 (set-up) three times.

The first zero (0) on the digital display will blink.

2. To set a nominal target value into wrench memory,

press Button #2 (store/send). As this button is

repeatedly pressed, numbers zero through nine (0-9)

will be displayed.

3. When the correct number is displayed on the first

digit, press Button #4 (setup). This will “hold” that

number and cause the second digit to blink.

4. Again, press button #2 (store/send) until the value

desired is displayed (0-9).

5. Press Button #4 (set-up) to “hold” this value and

cause the third digit to blink.

6. Continue the same steps above to set the values for

the third and fourth digits.

7. After pressing Button #4 (set-up) on the last digit, the

decimal point will be blinking. This “point” can be

placed in three different locations by pressing Button

#2 (store/send). Press Button #4 (set-up) when the

decimal point is in the desired location.

•

TO SET PERCENTAGES OF TOLERANCES:

1. Press Button #4 (set up), until the first

digit of two in the upper right corner is

blinking.

2. This will be the first of two digits in the (+) maximum

tolerance percentage. Again, as before, press Button

#2 (store/send) until the first digit is set at the

FlASHING desired value. Press Button #4 (set-up)

to accept this value and move to the next blinking

number.

3. Repeat the above procedure for the

second digit. When the desired digit is

displayed, press Button #4 (set-up). The

maximum tolerance is now entered.

4. The first digit of the (-) minimum tolerance should

be flashing. Press Button #2 (store/send) to scroll

through numbers (0-9). Press Button #4 (set-up) to

accept this value and move to the second flashing

digit. Press Button #2 (store/send) to scroll through

numbers (0-9) until the second desired number is

displayed.

NOTE:

Review the entire LCD at this time.

If everything is as desired, press Button #3

OPERATING INSTRUcTIONS

(recall) to accept

all parameters into wrench memory.

These parameters will remain in memory until they are

changed.

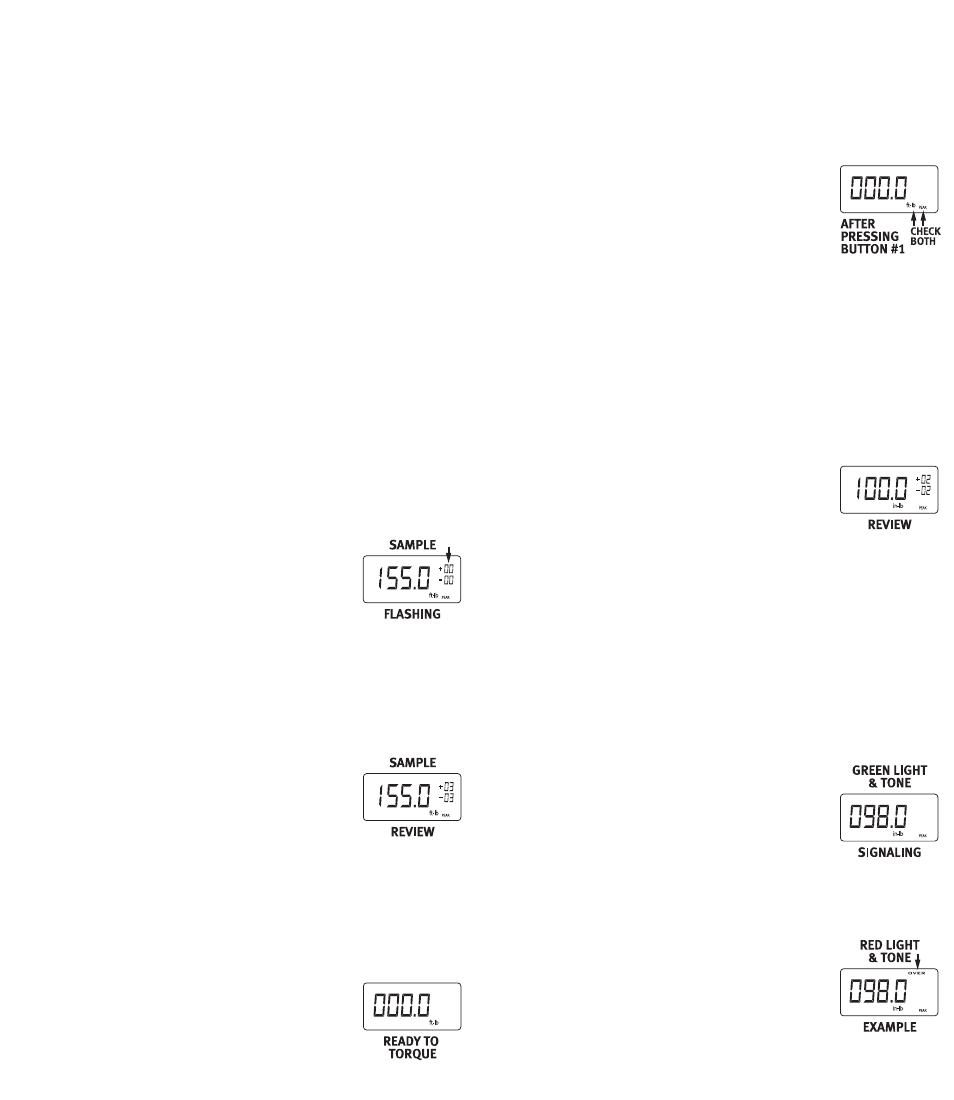

EXAMPLE SET-UP

To set a 250 in.lb. Computorq II to a

nominal “target” value of 100 in.lbs. +/-2%

the following steps would be necessary:

1. Press Button #1 to turn the wrench “on”

( check to see if “peak” is active

2. Press Button #4 twice and verify if the active torque

units are in in. lbs.

3. Press Button #4 one more time to activate the first

blinking “0”.

4. Press Button #2 until the number “1” is displayed.

5. Press Button #4 five times to scroll through the three

remaining zeros and the decimal point placement.

6. Press Button # 4 one more time to scroll through

the first zero of the (+) maximum

percentage. The second digit should be

blinking.

7. Press Button #2 until the number “2” is

displayed on the second digit.

8. Press Button #4 twice to the second digit of the (-)

minimum percentage.

9. Press Button #2 until the number ‘2” is displayed on

the second digit.

* Review Entire LCD at this time.

10. Press Button #3 to place all above parameters into

memory of wrench.

PLEASE NOTE: The wrench will sound an audible signal

and a green light will flash when the

applied torque to the wrench reaches the

lower acceptable torque limit of 98 in.lbs.

(100 in.lbs. - 2%). The green light and

audible tone will continue until the torque

value reaches the maximum preset limit of 102 in.lbs.

(100 in.lbs. RED LIGHT + 2%). The red & green lights

will flash and intermittent tones will sound if the &

TONE torque value exceeds the maximum

percentage allowed. Loud audible tones

and flashing lights will continue even

when an over torque (of the range of the

wrench) condition occurs. The display

will then show “OVER” in small letters in the extreme

000.0

171.5

000.0

171.5

000.0

171.5

000.0

171.5

000.0

171.5

000.0

171.5

000.0

171.5