Servicing augers, Shave piate and skid shoes – Craftsman 247.886640 User Manual

Page 16

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Remove the frame cover underneath the snow

thrower by removing six self-tapping screws. For

tocation of the frame cover, see Figure 19.

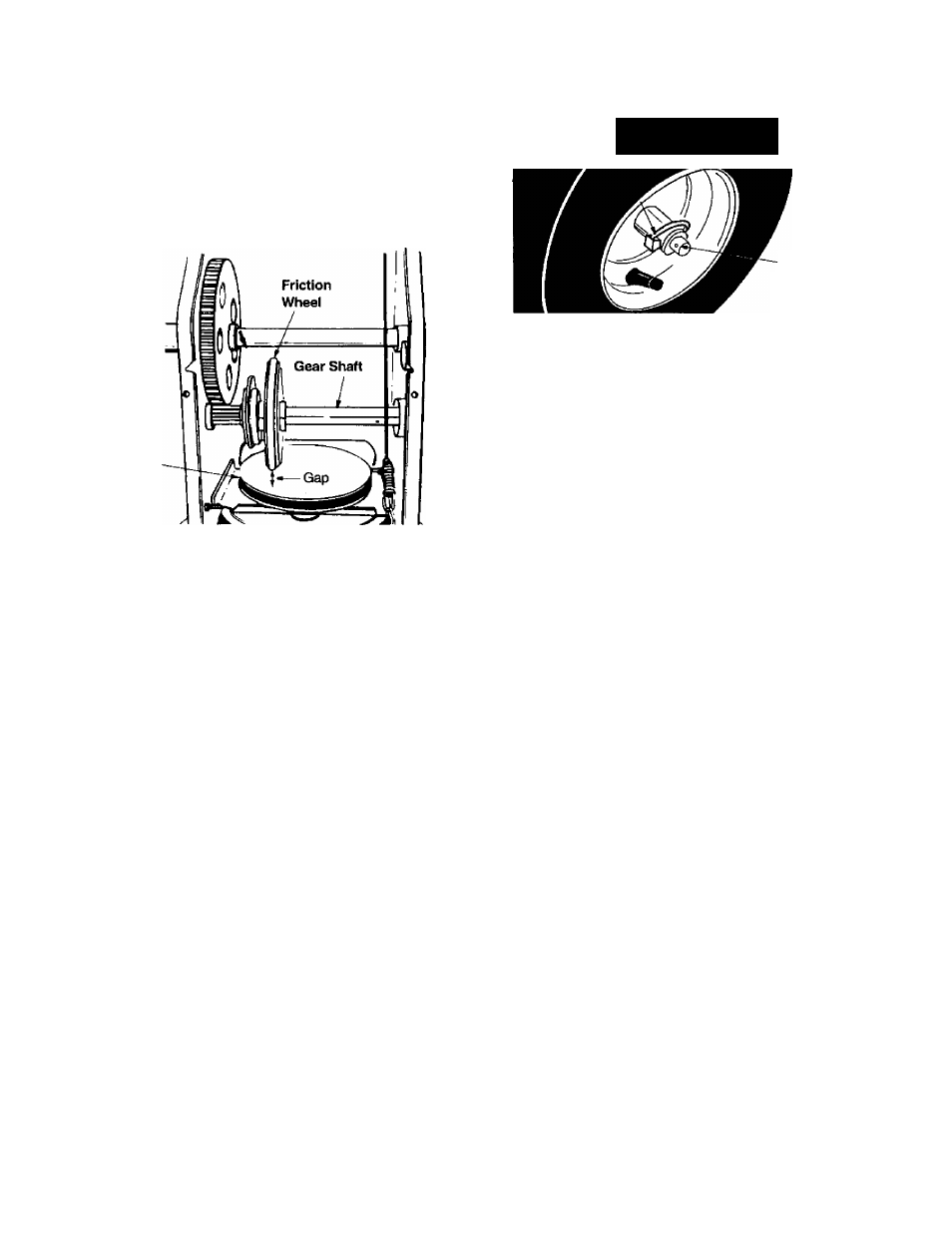

When the traction control is released, there must be

clearance between the friction wheel and the drive

plate in all positions of the shift lever. When the

traction control is engaged, the friction wheel must

contact the drive plate. See Figure 20.

Drive

Plate

Figure 20

•

If any one of these are not occuring, adjustment is

necessary. Follow the steps below to adjust the

traction control.

•

Loosen the lock nut on the traction control cable

and thread the cable in or out as necessary.

Tighten the lock nut to secure the cable when

correct adjustment is reached. Reassemble the

frame cover.

NOTE:

If you placed plastic under the gas cap earlier,

remove it now.

Auger Control

•

To adjust the auger clutch, refer to Final Assembly

and Adjustments on page 9.

Carburetor

A

WARNING:

If any adjustments need to be

made to the engine while the engine is running

{e.g. carburetor), keep clear of all moving

parts. Be careful of muffler, engine and other

surrounding heated surfaces.

•

Minor carburetor adjustment may be required to

compensate for differences in fuel, temperature,

altitude and load.

Drive Wheels

•

The wheels may be adjusted for two different

methods of operation. Follow the steps below for

adjustment. See Figure 21.

Klick Pin in Hub

ole and Inner Axle Hole

Outside

Hole In Axle

Figure 21

One Wheel Driving

•

On the right side of the unit, place klick pin in the

outside axle hole only. Do not place pin through

wheel hub. This position gives power drive to the

left wheel only, making the unit easier to maneuver.

Both Wheels Driving

•

Rotate wheel assembly to align hole in the hub with

the inner hole on the axle shaft. Insert klick pin in

the hole. Outer axle shaft hole should be visible.

See Figure 21.

A

WARNING:

Before servicing, repairing, or

inspecting, disengage all clutch levers and

stop engine. Wait until all moving parts have

come to a complete stop. Disconnect spark

plug wire and ground it against the engine to

prevent unintended starting.

Servicing Augers

•

The augers are secured to the spiral shaft with two

shear bolts and hex lock nuts. See Figure 16. If you

hit a hard foreign object or ice jam, the snow

thrower is designed so that the bolts may shear.

•

If the augers will not turn, check to see if the bolts

have sheared. Replacement shear bolts and hex

lock nuts have been provided with the snow

thrower. When replacing bolts, spray an oil

lubricant into shaft before inserting new bolts.

Shave Piate and Skid Shoes

•

The shave plate and skid shoes on the bottom of

the snow thrower are subject to wear. They should

be checked periodically and replaced when

necessary.

•

To remove skid shoes, remove the four carriage

bolts, cupped washers and hex nuts which attach

them to the snow thrower. Reassemble new skid

shoes with the four carriage bolts, cupped washers

(cupped side goes against skid shoes) and hex

nuts. See Figure 22.

16