Lubrication, Wheels, Chute directional control – Craftsman 247.886640 User Manual

Page 14: Auger shaft, Gear shaft, Drive and shifting mechanism, Gear case, Friction wheei, Engine maintenance

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Lubrication

A

WARNING:

Before lubricating, repairing, or

inspecting, disengage all clutch levers and

stop engine. Wait until all moving parts have

come to a complete stop. Disconnect spark

plug wire and ground it against the engine to

prevent unintended starting.

IMPORTANT: When lubricating engine or draining oil,

avoid dripping oil onto transmission parts.

Wheels

* Oil or spray lubricant into bearings at wheels at

least once a season. Pull klick pin, remove wheels,

dean and coat axles with a multipurpose

automotive grease. See Figure 15

Klick Pin

Oil bearings

or spray lubricant

Axle

Figure 15

Chute Directional Control

•

The worm gear on the chute control should be

lubricated with multipurpose automotive grease.

Auger Shaft

•

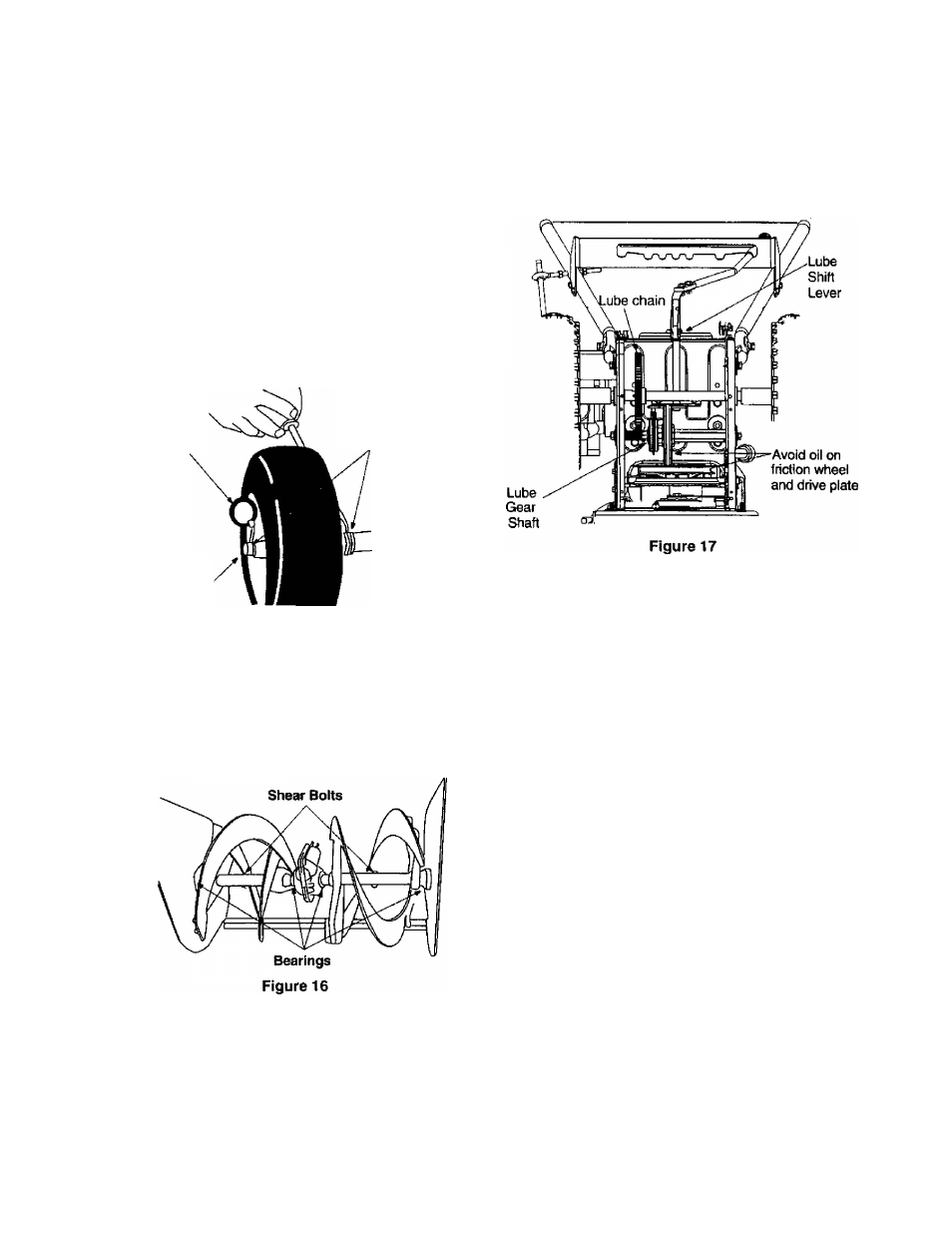

At least once a season, remove shear bolts on

auger shaft. Oil or spray lubricant inside shaft and

lubricate the auger bearings. See Figure 16.

Gear Shaft

• Lubricate the gear shaft with a good all-weather

multi-purpose light grease at least once a season or

after every 25 hours of operation. Keep alt grease

and oil off the friction wheel and drive plate.

Drive and Shifting Mechanism

• Remove rear cover. Oil any chains, sprockets,

gears, bearings, shafts, and shifting mechanism at

least once a season. See Figure 17. Use engine oil

ora spray lubricant. Avoid getting oil on rubber

friction wheel and aluminum drive plate.

Gear Case

•

The worm gear case has been tilled with grease at

the factory. If disassembled for any reason,

lubricate with 2 ounces of shell grease.

IMPORTANT: Do not overfill the gear case. Damage to

the seals could result. Be sure the vent plug is free of

grease in order to relieve pressure.

Friction Wheei

•

The rubber on the friction wheel is subject to wear

and should be checked after 25 hours of operation,

and periodically thereafter. Replace the friction

wheel rubber if any signs of wear or cracking are

found following instructions on page 18.

Engine Maintenance

Engine Oil

Only use high quality detergent oil rated with API

service classification SF, SG or SH. Select the oil’s

SAE viscosity grade according to the expected

operating temperature.

colder

32° F-

■ warmer

5W30

SAE30

Viscosity Chart

14