Adjustments, Applications, Cutting with your compound miter saw – Craftsman 315.212100 User Manual

Page 19: Crosscutting

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

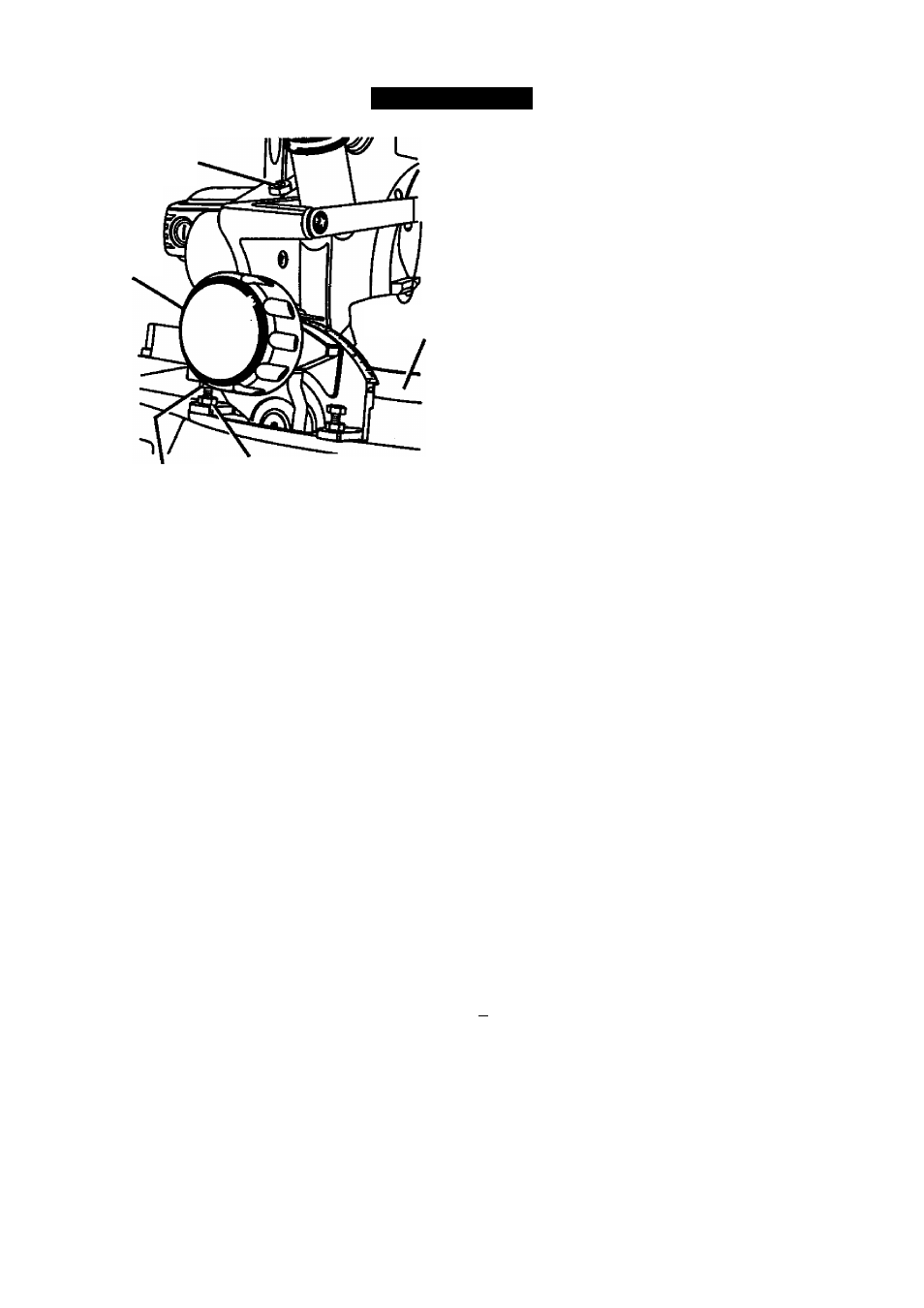

ADJUSTMENTS

DEPTH STOP

ADJUSTMENT

SCREW

BEVEL

LOCK KNOB

MITER

TABLE

POSITIVE

STOP ADJUSTMENT

SCREW FOR 0° ANGUS

LOCKNUT(S)

Fig. 25

■ Lower the blade Into the zero clearance throat

plate of the miter table. Check blade clearance

and maximum cutting distance (distance from

fence where blade enters) to frcmt of miter table

slot.

■ Readjust if necessary.

A WARNING:

Do not start your compound miter

saw without checking for interference between

the blade and the miter table support. Damage

could result to the blade If it strikes the miter

table support during operation of №e saw.

■ Tighten the hex nut with a 17 mm wrench or

adjustable wrench.

■ To prevent the depth stop adjustment screw from

turning while tightenin^the hex nut, carefully hold

it with the hex key wrench while tightening the

hex nut.

APPLICATIONS

(Use only for the purposes listed below)

■ Cross cutting wood and plastic.

■ Cross cutting miters, joints, etc. for picture frames,

moldings, door casings, and fine joinery.

Note: The 104 tooth crosscut blade provided is fine

for most wood cutting operations, but for fine joinery

cuts or cutting plastic, use one of the accessory

blades available from your nearest Sears store.

WARNING:

Before starting any cutting

operation, clamp or bolt your compound miter

saw to a workbench. Never operate your miter

saw on the floor or in a crouched position.

Failure to heed this warning can result in serious

personal injury.

CUTTING WITH YOUR COMPOUND

MITER SAW

WARNING:

When using a work clamp or

Oclamp to secure your workpiece, clamp

workpiece on one ¿de of the blade only. The

workpiece must remain free on one side of the

blade to prevent the blade from binding in

workpiece. The workpiece binding the blade will

cause motor stalling and kickback. This situation

could cause an acddent resulting in possible

serious personal injury.

CROSSCUTTING

See

Figure 26.

A crosscut is made by cutting across the grain of №e

workpiece. A straight crosscut is made with the miter

table set at the zero degree position. Miter crosscuts

are made with the miter table set at some angle other

than zero.

TO CROSSCUT WITH YOUR MITER

SAW:

■ Pull out the lock pin and lift saw arm to its full

height.

■ Loosen the miter lock handle. Rotate tiie miter

lock handle approximately one-haK turn to the left

to loosen.

■ Press the miter lock plate down with your thumb

and hold.

■ Rotate the control arm until the pointer aligns with

the desired angle on the miter scale.

■ Release the miter lock plate.

Note: You can quickly locate 0°, 22-1/2*’ left or

right, smd 45* left or right by releasing the lock

plate as you rotate the control arm. The lock plate

will seat itself in one of the positive stop notches,

located in the miter table frame.

■ Tighten the miter lock handle securely.

A WARNING:

To avoid serious personal injury,

always tighten the miter lock handle securely

before making a cut. Failure to do so could result

in movement of the control arm or miter table

while making a cut.

19