A. air filter, C. starter rope, General maintenance – Craftsman 358.797922 User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

GENERAL MAINTENANCE

A. Air Filter

A air filter decreases engme performance and

increases fael consumptiott.

Clean the Air Filt^

• Freqiuenilj;

* Alwa^^ clean after 5 tanks offnel or 5 hoars

of operatioiit whichever is lessi.

Follow these steps;

L Move the (hote lever to “FhH", Figure 11,

2.

Eemove the air SIter cover on top of the unit (tm

’ der the handle). Blgnie 13.

3. Eemove the air fihec FSpselS.

4.

Wash the air filter wiffi soap and water.

ICACTIOI^ To avoid creating fire hazard, do not

cdeah filter in gasoline or other fianunable solvent.

5. Simeeze the air filter di

7

6. Add 4 or 5 drops of oil to die the air filter.

NOTEi AvoM soaHng the air filtcr wilh oQ.

Air Filter

Cover

Air Filter

Figure 13

7. Sipeeze the air filter to distribute od.

8. Eressembie the air filter onto the cov^

I CAUTTONt I 'flic holes in the air filter must be fit*

ted over the posts on the air filter'Ooven

When.

In

stalling the air filter/covér assembly, be sure that

the filter dees not hang on the choke lever screw.

9. Beassemble ah fil^/cover assemble to unit. Be

tún» choke lever to the

position. Figure 11.

BWtTTTT *¥*AXnr

1. Never use gasoline that is more than

2

months old in-a fuel mixture. Gasoline heg^

, to break down after a-short period of time and

fbrm compoundb that cause hard starting and

dam^ in 2-^cl8 en^es.

2.

Inspecttheunitfor£uelleakseaohtime itis

used. R^air or replace parts as n^ssary.

3.

4.

Using a ftifl mix orgq^oiine over 2 months,

oldteiUcmtse the engùteto bedifficultor im-

poeaihfe

to staH.

■

Empty the fuel tank before storing the unit.

Use up fiiel left: its the carburetor by starting the

engine and letting it run tmtil it sh^

C. STARTER ROPE

Replace the starter rope if the rope breaks or is

badly worn.

NOTE: Whm replacing an unbroken rope,^ cut the

rope and allow the rope to rewmd onto the pulley.

Latch Area

A

wabning

Do

not

remove

the

Pulley

whe»

replacing the

sitoirthr

rope..

Alweys

w^ar

eye

^tit^lon

when

servicing the starter rope. The recoil spring lo

cated beneath fite pulley, is under tension. If the

ispringpops out, serious inhiry can result.

To repair or replace;

L Dlscoimect spark plug wire fiom the spmk|dt|g; a

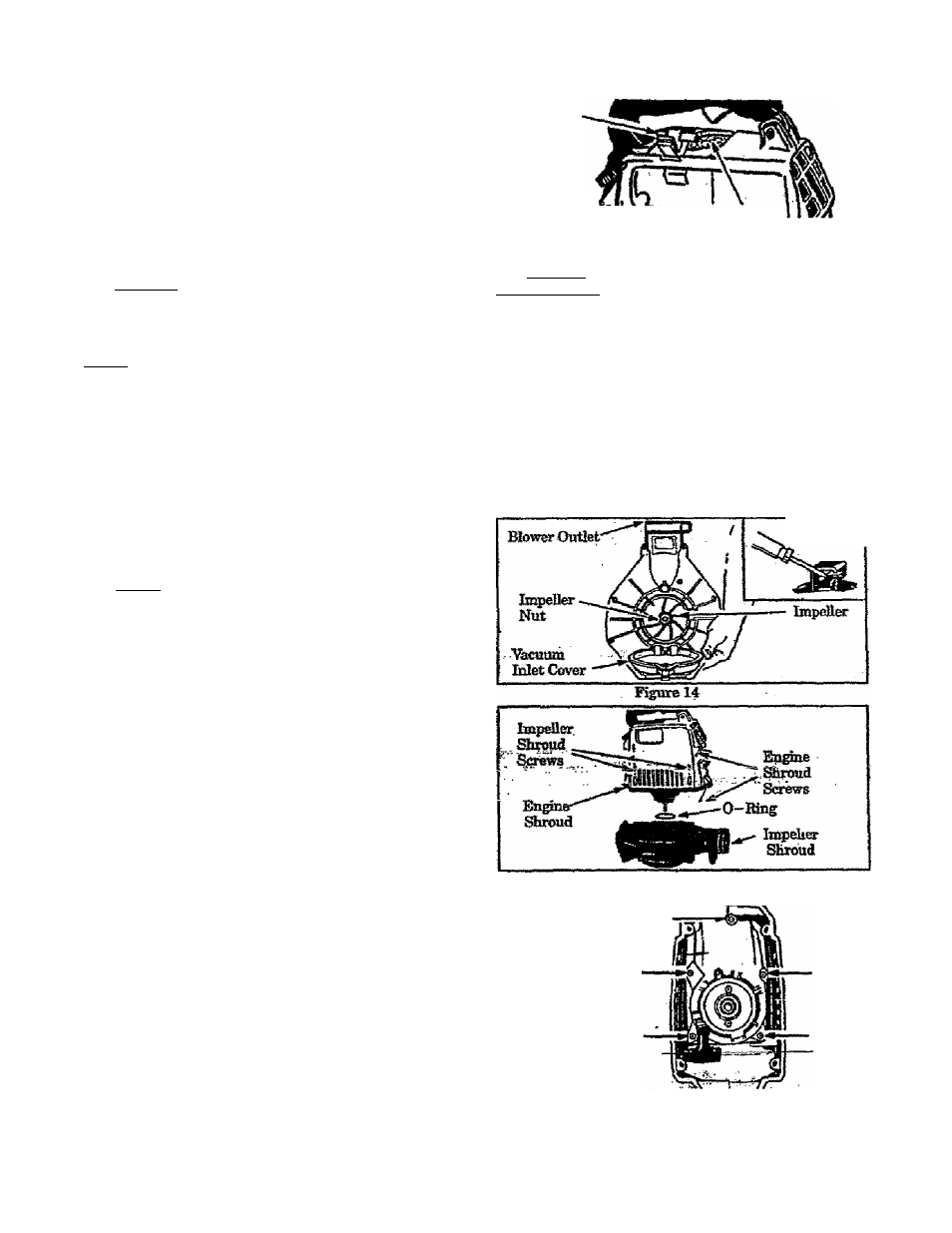

2., ^unit,blow^cmtletup,oii aflatsumce.jJi^.i

mel4. Opén the vacunmiukfe cover i^Mhnvs:

;lEsertascrewdrivm^.intothetefccho|íénhIig:Fig-

..;; ure 14(m&et).

•

b. Gen% twist the screwdriver while openmg the

vacuttm inkt cover with your other hand.

3. Eemove the impeller nut and washers while hold

ing the impeller. Figure 14.

4.. Eemosre the 4 impwer shroud screws. Figuréis.

Then, remove the 2 engine shroud screws located

bytheq>arkplug. Figure IS. Itemoré the impel

id

v&mB-m-

5. Emove the 5 screws &mu

£оиШ|^:

then remove the pulley housing and pu0ey from

the engine. Figure 16.

6. Removethe rope retainer screw frompuBey; then,

remove the broken piece of repe, if ary. Figure 17,

7. Gi^ the puDey ratchet and wind the puUoy

dbekwise until the pulley stops. Then, slowly im

wind the pulley counterdodmse until the pulley

notch Is aHmed with the pulley Hbiasrag notch.

Figure 17. Insert the hex wrench into the hole

formed by the aligned notches. Fimre Ws ................

Figwe 15 .

E^<íve

Screws

PiiSirfe 16

-10-