Operation – Craftsman 315.175341 User Manual

Page 12

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

OPERATION

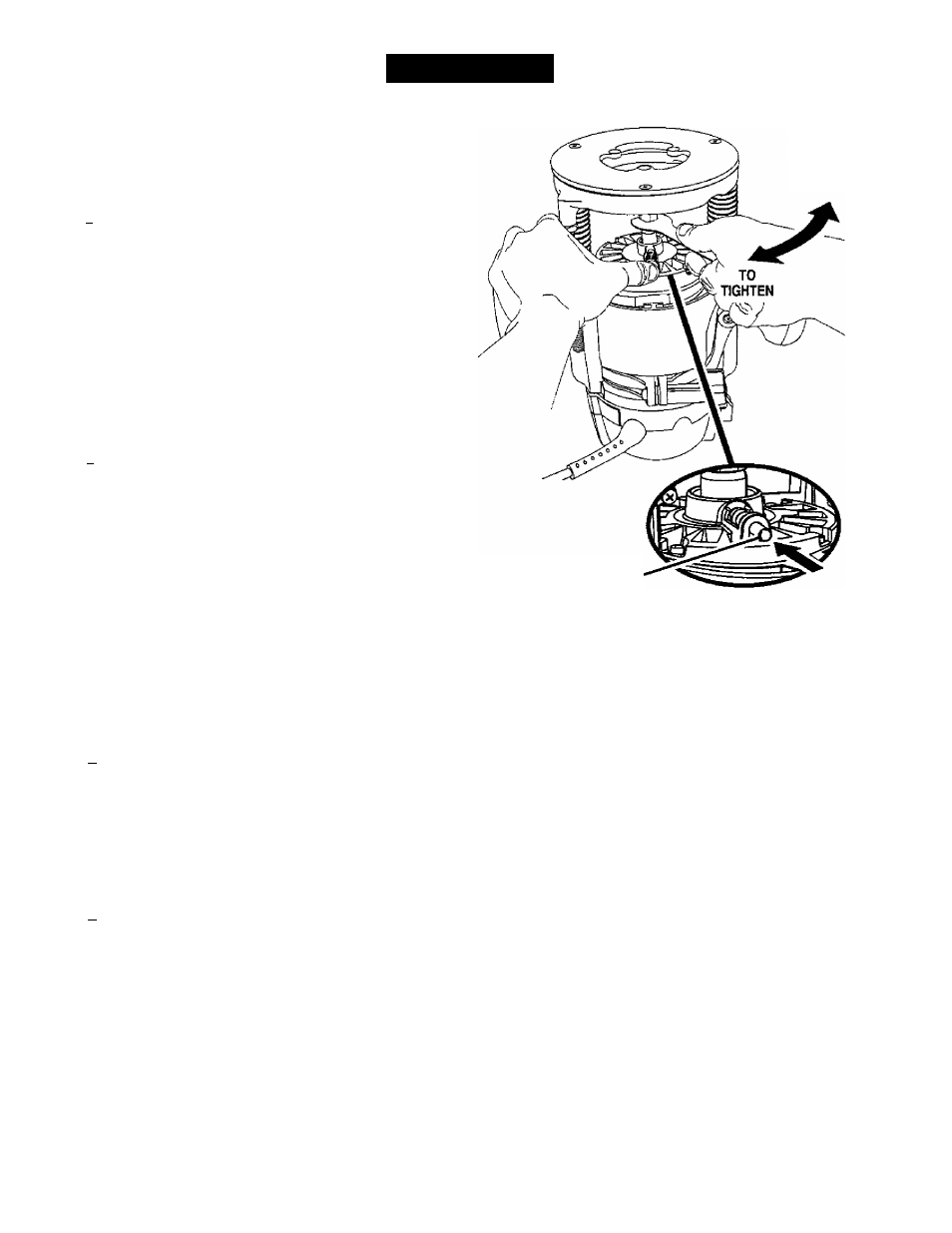

REMOVING/INSERTING CUTTERS

S e e F ig u re 7 .

Follow these steps to remove or insert cutters.

1. Unplug the router.

^

WARNING:

Failure to unplug the tool could result

in serious injury due to accidental starting.

CAUTION: To prevent damage to the spindle or

spindle lock, always allow motor to come to a

complete stop before engaging the spindle lock.

2.

Lay the router down on a workbench in order to

gain easy access to collet nut.

3.

Depress and hold the spindle lock button.

4.

Loosen the collet nut by turning it counterclockwise

with the wrench provided.

^

WARNING:

If you are changing a cutter

immediately after use, be careful not to touch the

cutter or collet with your hands or fingers. Always

use the wrench provided.

5.

Choose one of these options:

■

T o re m o v e th e c u tte r:

Remove the cutter from the

collet.

■

T o in s e rt th e c u tte r:

a) Insert the shank of the cutter until the shank

bottoms out, then pull it out 1/16 in. {1.6 mm)

to allow for expansion when the bit gets hot.

b) Tighten the collet nut securely by turning it

clockwise with the wrench provided.

c) Release the spindle lock button.

^ WARNING;

If the collet nut is not securely

tightened, the cutter may detach during use

causing serious personal injury.

^ WARNING:

Do not use cutters with undersized

shanks. Undersized shanks will not tighten properly

and could be thrown from the tool causing injury.

^ WARNING:

Do not use cutters that are larger in

diameter than the opening in router base. Use of

such cutters will come in contact with the router

base and damage both the cutter and router base.

This situation could also cause possible loss of

control or create other hazardous conditions that

could cause possible serious personal injury.

TO

LOOSEN

SPINDLE

LOCK

BUTTON

Fig. 7

ADJUSTING DEPTH OF CUT

Proper depth of cut depends on several factors: the

horsepower of the router motor, the type of cutter, and

the type of wood. A lightweight, low horsepower router is

designed for making shallow cuts. A router with a high

horsepower rating can safely cut deeper. Small cutters,

such as vetning bits with 1/16 in. (1.6 mm) cutting

diameters, are designed to remove only small amounts

of wood. Large cutters, such as straight-flute bits, are

made to remove larger amounts of wood. You can make

deeper cuts in soft woods, such as white pine, than in

hardwoods, like oak or maple.

Based on these considerations, choose a depth of cut

that will not place excessive strain on the router motor. If

you find that extra force is needed or that the motor

speed slows down considerably, turn off the router and

reduce the depth of cut. Then, make the cut in two or

more passes.

When routing a groove that is too deep to safely cut in

one pass, it is best to make the cut in severai passes.

We recommend that cuts be made at a depth not

exceeding 1/8 in. (3.2 mm) and that several passes be

made to reach deeper cuts.

Adjusting the depth of cut for the plunge router is

different from adjusting the depth of cut for the fixed

router.

12