Type of tooth, Changing blade speed – Craftsman 351.214300 User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

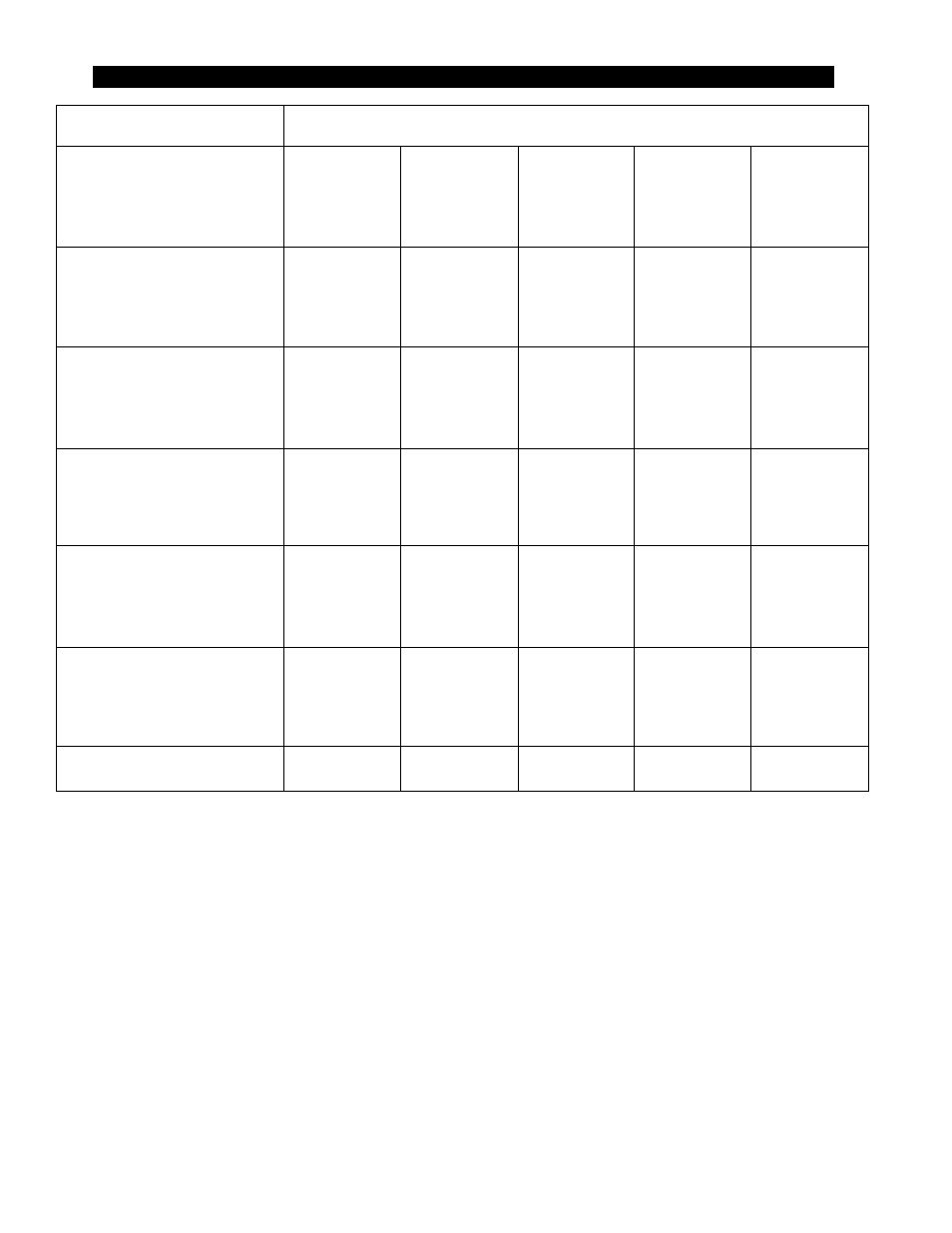

BLADE SPEED AND BLADE PITCH CHART (FEET PER MINUTE/TEETH PER INCH)

MATERIAL

THICKNESS:

1/4"

1/4-1"

1-3"

3-6"

6-10"

High carbon steel

230/18

200/14

200/10

150/6

150/4

Free cutting steel

200/18

150/14

130/12

100/6

100/4

Ferro-manganese

200/18

156/14

130/12

100/8

100/4

Ferro-nickel

165/18

130/14

100/12

75/8

75/4

Ferro-nickel-chrome

130/24

100/18

75/14

66/8

66/6

Ferro-molybdenum

150/18

130/14

100/12

75/8

75/6

Ferro-chrome (med.)

165/18

100/14

75/12

66/8

66/6

Ferro-chrome (high)

100/24

75/14

66/10

66/8

66/6

Manganese steel

180/18

150/14

115/12

100/8

66/4

Ferro-tungsten

150/18

100/14

75/12

66/8

66/4

Ferro-chrome-vanadium

165/18

100/14

75/12

66/8

66/4

Ferro-silicon-manganese

150/18

130/14

100/10

75/6

75/4

Machinery steel

180/18

130/14

115/12

100/6

66/4

Ordinary tool steel

130/24

100/18

100/14

80/8

75/4

High speed steel

100/24

75/14

66/12

66/8

66/4

Stainless steel

130/18

100/14

75/10

66/8

66/4

Thick iron plate

165/18

130/12

75/10

66/8

66/4

Cast iron

200/18

200/14

1 50/12

75/8

75/4

Nickel cast iron

200/18

150/12

100/8

66/6

66/4

Forgeable cast iron

200/18

165/14

150/10

130/6

130/4

High grade cast iron

150/18

130/14

100/10

75/6

66/4

Coarse cast iron

200/18

165/14

130/10

75/6

75/4

Tombac

1480/18

1000/12

750/8

95/6

295/4

Bronze

245/18

245/12

225/10

200/6

150/4

Phosphorus-bronze

490/18

295/14

200/10

150/6

150/4

Nickel aluminum bronze

490/18

295/12

225/10

150/6

150/4

Magnesium-bronze

295/18

245/12

225/10

150/6

150/4

Hard aluminum

2000/18

2000/10

2000/8

2000/6

1480/4

Aluminum

2000/18

1650/10

1300/6

820/4

490/3

Copper

395/18

295/12

245/8

150/6

150/3

Fibers

1480/24

1300/18

1000/6

750/4

750/3

Asbestos

1300/24

1000/18

660/14

490/10

330/6

TYPE OF TOOTH

• The shape of teeth are varied to achieve specific

cutting results. A blade cuts work by removing

material. Blade teeth must scrape a chip of

workpiece away on each cut.

• The shape of gullet between teeth determines how

much material can be taken out with each blade

tooth.

• There should always be at least three teeth in con

tact with workpiece to avoid shocking blade. Blade

shocking occurs when pitch is too large and blade

tooth encounters too much material. This can strip

teeth from blade.

• When pitch is too small, gullets of teeth will fill up

leading to creation of excess heat.

• Rake angle is the angle which the cutting face of

tooth makes with a line perpendicular to the back of

blade. A 0° rake angle is used to cut hard materials.

• Positive rake angle blades are used to cut softer

materials. Softer materials require more aggressive

chip removal.

• Larger gullets provide for faster removal but have to be

limited in size because they make blade teeth weaker.

• Blade teeth will also vary in the way that teeth have

been set from one side to the other. A wider set is

used for contour work because wider kerf allows

operator to cut tighter curves.

CHANGING BLADE SPEED

Refer to Figure 15.

WARNING: Never adjust blade speed unless machine

is running or damage to saw may result.

• Blade speed is adjusted by rotating handwheel (Key

No. 50) while machine is running. Rotate handwheel

clockwise to increase blade speed. Rotate hand

wheel counterclockwise to decrease blade speed.

The blade speed is shown on LED display located

above switches.

8