Craftsman 137.212290 User Manual

Page 14

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

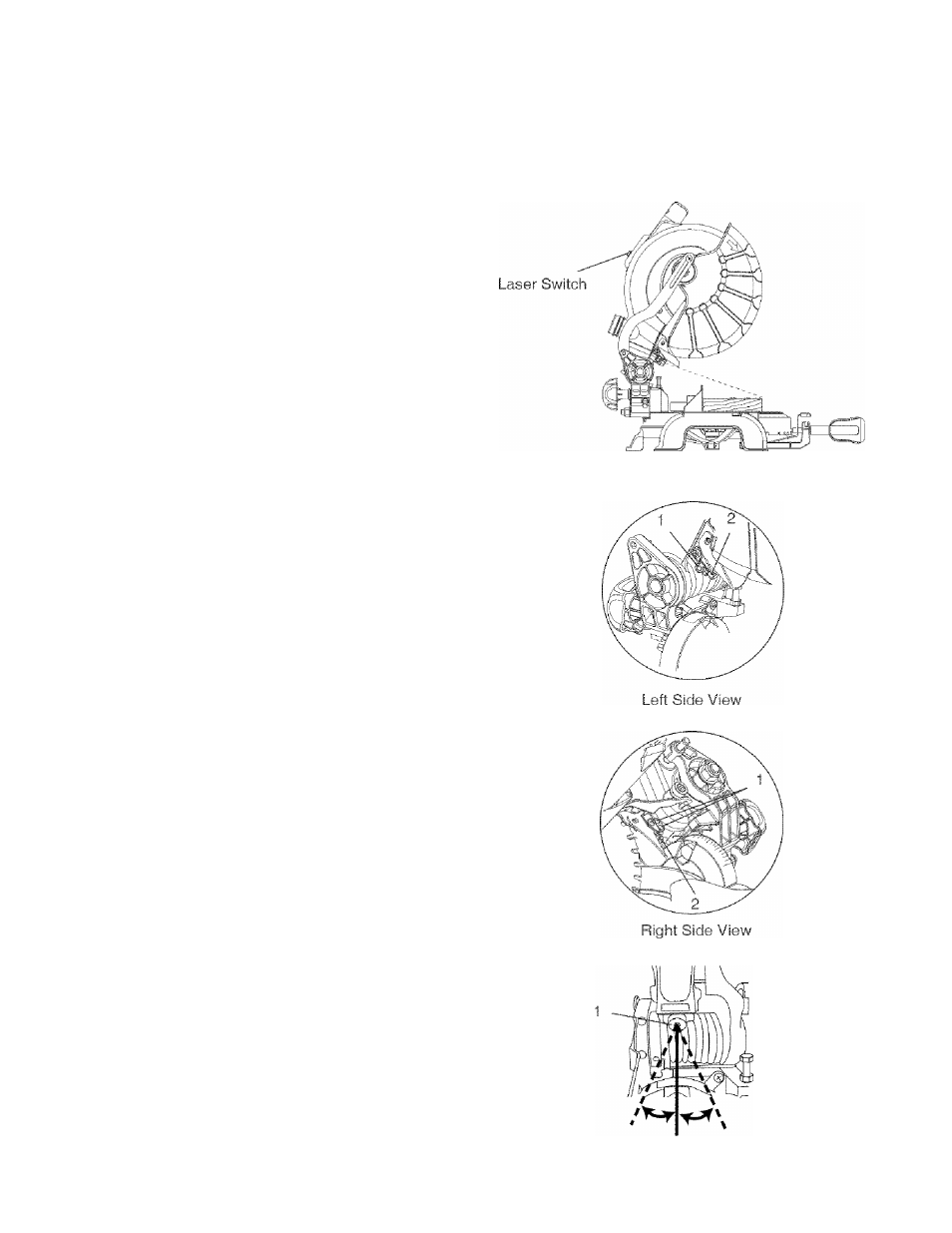

ALIGNING THE LASER BEAM

A WARNING

For your own safety, never connect the plug to

power source outlet until all the adjustment steps

are complete and you have read and understood the

safety and operational instructions.

The laser beam must always be correctly aligned with

the blade to ensure straight, even cutting.

Your tool is equipped with the Laser Trac® cutting

guide using Class Ilia laser beams. The laser beam will

enable to preview the saw blade path on the stock to

be cut before starting the miter saw. This laser guide is

powered by the transformed alternating current supply

directly through the power lead. The saw must be

connected to the power source and the laser on/off

switch must be turned on for the laser line to show.

A

WARNING

AVOID DIRECT EYE CONTACT

Laser radiated when laser guide is turned on. Avoid

direct eye contact. Always un-plug the miter saw

from power source before making any adjustments.

NOTE; All the adjustments for the operation of this

machine have been completed at the factory. Due to

normal wear and use, some occasional readjustments

may be necessary.

A. Check Laser Beam Alignment

1. Mark a 90° straight line across a board to serve as a

“pattern line” to test laser alignment. Lay the board

on the miter table.

2. Plug saw into outlet and turn on the laser beam and

line it up with the pattern line.

3. Lower saw blade to pattern line and if blade is

not flush with the pattern tine, adjust as follows in

procedures (B).

B. Adjusting the Angie of the Laser Trac® (Fig. N-2)

1. Turn the laser element (1) in the desired direction

to adjust the laser angle. NOTE: Do not adjust the

laser more than !4 turn in either direction as this may

damage the laser. There are two flat sides on the

laser element where you can position an adjustable

wrench for your adjustment.

C. Aligning The Laser Beam

1. Loosen only

’/2

turn at a time the three set screws (1).

2. Adjust laser by turning the left side set screw

clockwise to shift the laser line to the right. To shift

the laser tine to the left, turn the right side set screws

V

2

turn at a time.

3. Once alignment of the laser is achieved,

tighten only

Vi

turn at a time the three set screws

{1). Start with the set screw on the left side of the

laser assembly, then with the front set screw on the

right side of the laser assembly.

Fig. N-1

Fig. N-2

14