Engine adjustments, Carburetor adjustments, Sparkplug – Craftsman 358.796131- User Manual

Page 9: E. engine adjustments, Operating instructions

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

For maximum performance and efficiency:

1. Always accelerate the engine to the desired

speed before cutting.

2. Never operate the engine at a higher speed

than necessary.

3. Always release the trigger and allow the en

gine to return to idle speed when not cutting.

OPERATING INSTRUCTIONS

Make sure the cutting head stops turning

when the throttle trigger is released and the

engine runs at idle speed.

For correction,

refer to “Carburetor Adjustments," below.

Stop engine by moving the ignition switch, to

the “OFF" position (Figure 8).

ENGINE ADJUSTMENTS

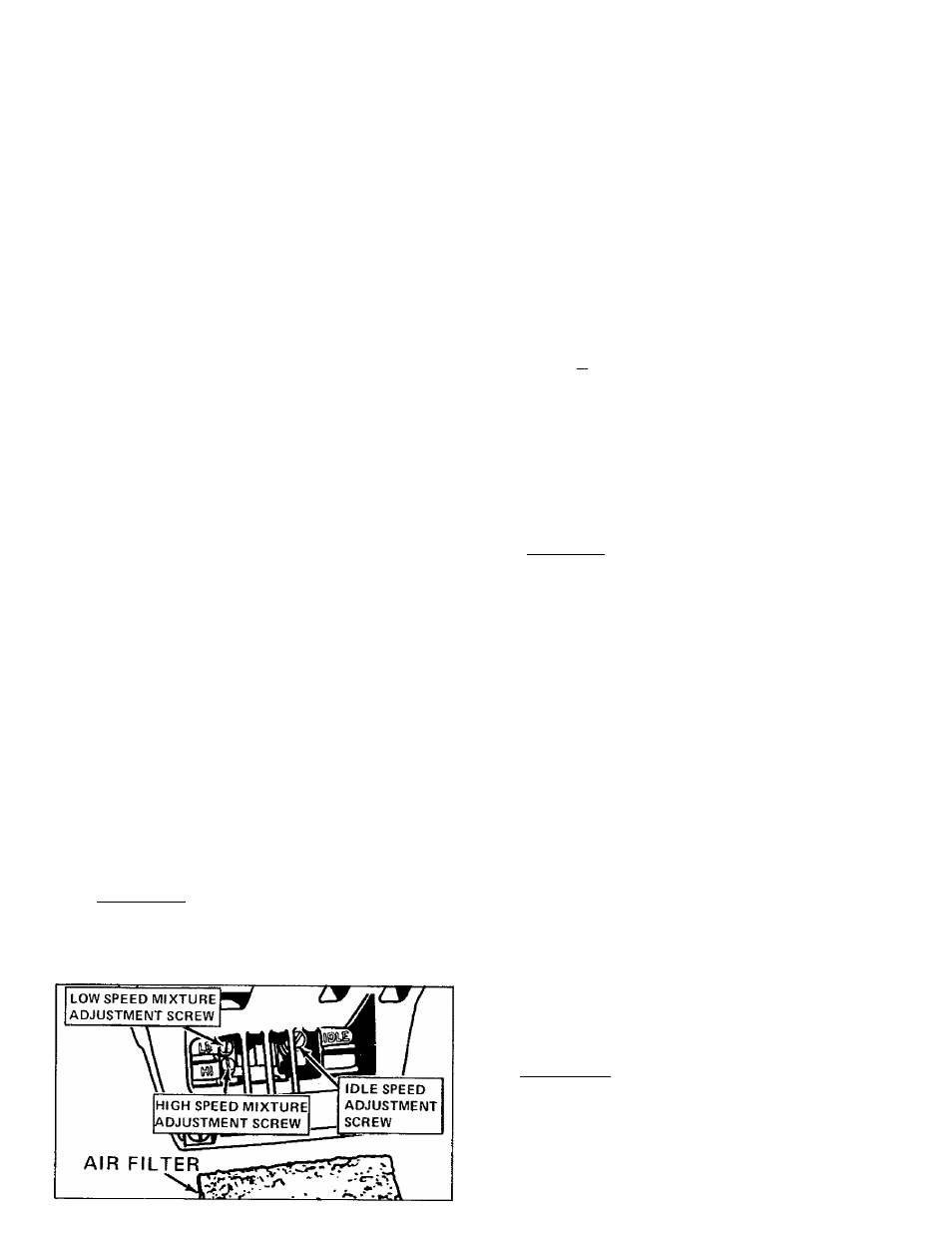

1. CARBURETOR ADJUSTMENTS

The carburetor has been carefully adjusted atthe factory.

Due to changes in altitude and operating conditions, your

carburetor may require adjusting. Tb make the adjust

ment follow the procedure below very carefully:

a. PREPARATION

1. ) Use fresh fuel mix with proper gasoline/

' oil ratio. See "Fuel Mixture”, page 7.

2.

) Make sure the cutting line extends at least

4 inches to provide correct load on engine.

3.

) Remove air filter ( Figure 10 ) and place

under spark plug wire for safe keeping.

4.

) Turn both low speed and high speed mixture

screws clockwise ^ A until fully closed,

but do not overtighten. Figure 10. Unscrew both

mixture screws one full turn counterclockwise

b. IDLE SPEED ADJUSTMENT

1. ) Turn Idle Speed Screw clockwise

until it stops. Do not overtighten. Open

screw one full turn counterclockwise.

2. ) Start the engine and cut grass for 3 min

utes to warm up engine.

3. ) Allow engine to idle.

4. ) Adjust Id le Speed Screw until engine continues

to run without stalling and without the cutting

head turning.

Turn screw clockwise

to increase

engine speed if engine stalls;

Turn screw counterclockwise to slow

engine down if cutting head

continues to turn.

c. LOW SPEED MIXTURE ADJUSTMENT

i

CAUTION:

I

High and low speed mixture settings

are highly critical adjustments. If set incorrectly per

manent damage will occur to the engine. Both the

low speed mix and the high speed mix sc/eivs

should be in the range of 3/4 to 1-1/4 turns open.

1

. )

2

. )

3.)

4.)

Allow engine to idle.

Turn Low Speed Mixture Screw clock

wise slowly. Note the position at

which the engine speed is increased.

Turn the screw slowly counterclockwise.

A . Note the position at which the

speed Is reddeed.

Set the screw mid-way between these two

extreme positions.

d.

IDLE SPEED ADJUSTMENT

1. ) Allow engine to idle.

2. ) Adjust the Idle Speed Screw until the

engine idles as fast as possible without

the cutting head or blade turning

2

.

3.

4.

ICAUTIONH

D

o

not operate engine at full throttle

for prolonged periods while making high speed

adjustments as damage to the engine can occur.

e.

HIGH SPEED MIXTURE ADJUSTMENT

1 ) Support the shaft so that the cutting head

is off the ground and will not contact anv

object.

Squeeze throttle trigger wide open

Turn the High Speed Mixture Screw slowly

clockwise until the engine speed is

reduced. Note position.

Turn the screw

slowly

counterclockwise

Stop when the engine just begins

to run rough. ^

5.} Turn the screw

slowly the minimum

amount

c l o c k w i s e - u n t i l the engine

runs smoothly.

f. CHECK ACCELERATION

Allow the engine to idle. Squeeze trigger and

check engine acceleration. If the engine

does not accelerate smoothly, you may have

to repeat steps “b.3.)" through “e."

NOTE:

Generally, by turning the low speed

screw counterclockwise A“*«* a small amount,

the unit will accelerate properly.

g. REINSTALL AIR FILTER

I CAUTION: I The air filter must be fitted into the

corners of the housing to avoid engine damage.

2. SPARKPLUG

Check spark plug periodically and replace as necessary.

Set the electrode gap at .025".

Figure 10