D. starter rope repair, Starter rope repair – Craftsman 358.796131- User Manual

Page 15

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

D. STARTER ROPE REPAIR

• Repair the starter rope If the rope breaks next

to the pulley.

• Replace the starter rope if the rope breaks 2-3

inches away from the pulley as the rope will be

too short to repair properly.

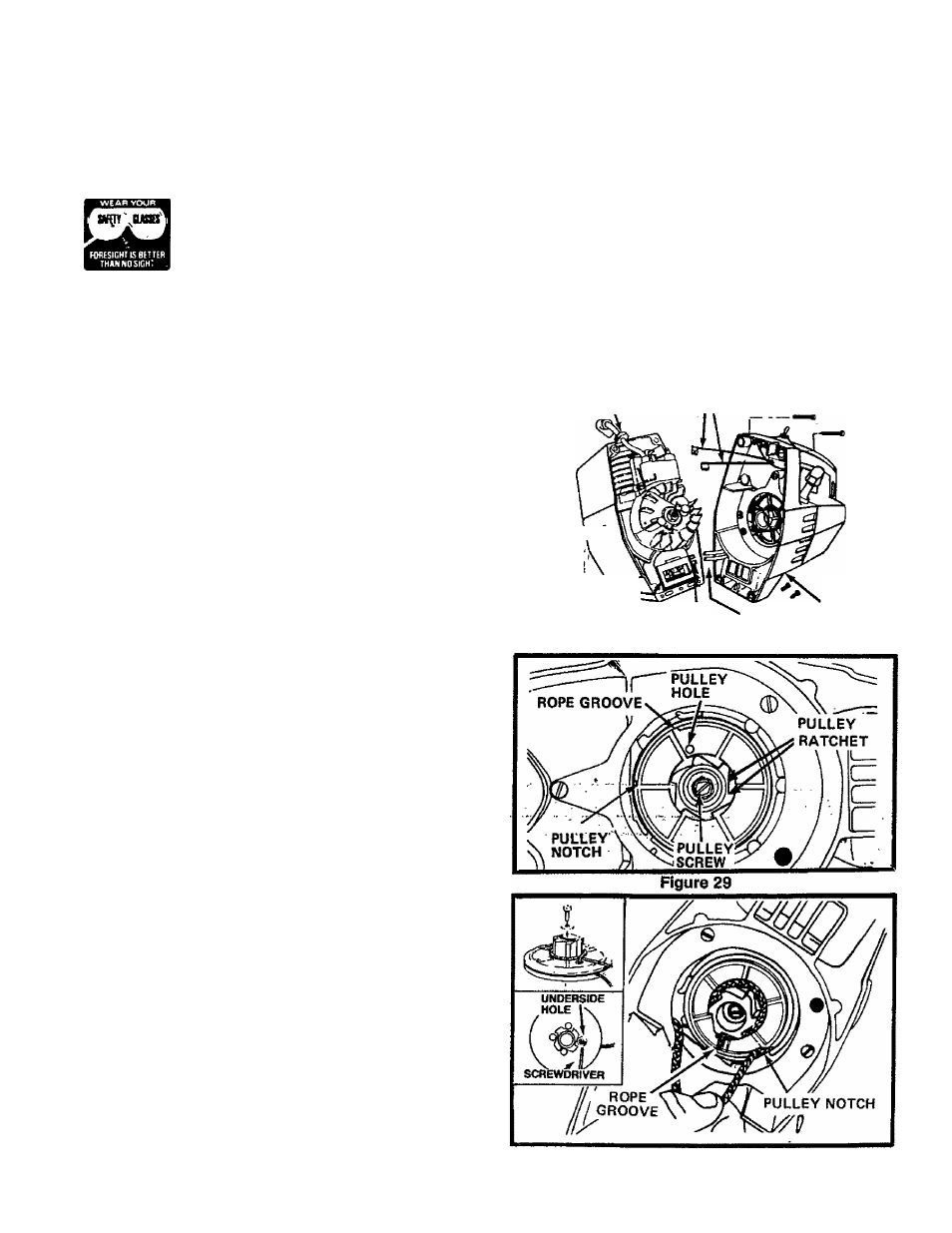

A

warning

Always wear eye protection when ser

vicing the starter rope. The recoil spring,

located beneath the pulley, is under ten

sion. If the spring pops out, serious per

sonal injury can result.

• To repair or replace:

NOTE;

Use caution when separating the

fan housing from the shroud to avoid

breaking or damaging the fuel line fittings.

1 . Drain all fuel from tank.

2. Remove the four (4) screws from fan

housing. Figure 28.

3. Carefully separate fan housing from shroud

about one {1) inch.

4. Disconnect fuel lines from fittings.

5. Disconnect ignition module wires. Figure

28.

6. Slide high tension lead grommet from slot

in fan housing.

7. Separate the fan housing completely from

the shroud.

8. If the starter rope is not broken, release

the spring tension by pulling about 12

inches of rope from the pulley and catch

the rope in the notch as shown. Figure 30.

NOTE:

The tension on the starter spring

will be released if the rope has broken.

9. Remove screw and pulley very carefully.

Figure 29.

The recoil spring which lies

beneath the pulley must stay In the hous

ing, flat against the bottom, lithe spring Is

disturbed, it will require considerable time

and effort to reinstall.

Twist the pulley

gently clockwise as you pull up to

release the spring,

10. Moveawayfromthefueltankandmelttheendof

the new rope to go into the pulley.

11

. Allowthemeltedendtodr{ponce,thenwhilerope

is still hot pull the melted end through a clean rag

to obtain a smooth, pointed end.

12. Insert rope through the rope exit hole in

the fan housing.

13. Guide rape inside pulley, then up through topside

pulley hole by pushing the rope from the under

side hole with a small object such as a

screwdriver.

14. Wrap rope counterclockwise around

pulley ratchet and tuck loose end back

under rope leaving a 1 /4 to 1 /2 inch

tail laying in the rope groove. Figure 30.

15. Wind all but about 12 inches of the rope

counterclockwise

around pulley.

16. Replace pulley in the housing. Be sure

the pulley is all the way down and the

spring is secured. Replace screw and

tighten. Figure 29.

17. Hold the 12 inch slack in the rope and

catch rope in pulley notch. Figure 30.

18. Hold the rope taut and make 2 complete

turns of the pulley counterclockwise

to place tension on the pulley.

Hold the pulley to retain tension.

19. Align pulley notch with rope exit hole,

pull starter handle to the full extent of the

rope and allow the rope to slowly wind

around the pulley.

NOTE:

While the unit is disassembled, in

spect the carburetor housing seal and

replace if worn. Figure 28.

20. Reverse procedure for re-assembly of fan

housing to shroud.

NOTE:

Make sure the fuel line with the

black stripe or solid color is installed on

Jhe inner fuel fitting.

GROMMET

IGNITION MODULE WIRES

SHROUD

CARBURETOR

HOUSING

seal

:

FUEL LINE FITTINGS

FAN

HOUSING

FUEL LINES

Figure 28

Figure 30

15