Taylor-Wharton KeepFull Telemetry System User Manual

Page 6

Installation

Before installing the telemetry unit inspect it carefully.

Report any damage to the carrier and Taylor Wharton

Customer Service. As shipped, the unit is operational and

ready to be installed on the tank. For installation on a

typical tank with an existing Contents Gauge follow these

steps.

1) Fill out the Bulk Vessel Registration Form supplied with

this manual and fax it to Taylor Wharton Customer

Service. This form, along with the Customer Informa-

tion Form, filled out at the time of purchase is used to

prepare your Internet Web Site.

2) Verify that the differential pressure transmitter span

(inches of water) covers the range required for the

tank.

3) Record the present liquid level and tank pressure as

indicated on the existing Contents Gauge Assembly.

Also, label the high and low-pressure instrument lines.

4) Close both instrument valves to isolate the existing

Contents Gauge Assembly from the tank. Open the

Instrument Bypass valve to equalize the pressure

between the high-pressure and low-pressure side of

the Contents Gauge Assembly.

5) Carefully loosen the connections at the Contents

Gauge Assembly to relieve any pressure and then

remove the assembly.

6) Identify the high (H) and low-pressure (L) sides of the

Differential Pressure Transmitter on the Telemetry Unit.

7) Mount the Telemetry Unit on the tank using the sup-

plied bolts. See figure 2. The Telemetry Unit bracket

is designed to mate to a typical bracket supplied with

the tank. If there is a mismatch some field adaptation

may be required.

8) Solar panel must be directed to maximize southern sun

exposure. Turn the solar panel by rotating the 45°

elbow as much as one-quarter turn to direct the panel

to a maximized southern sun exposure. Caution, only

apply torque to 45° elbow using appropriate

wrenches.

9) Install an appropriate pressure gauge in the tee at the

low-pressure side of the telemetry unit. See figure 2.

10) Connect the instrument lines and then open the

instrument valves.

11) Leak test all connections using a suitable liquid leak

detector.

12) To obtain the current reading momentarily hold the “Fill

Button” until you see “FILL” on the display. The screen

will blink with the current reading. If “ERROR” is

displayed the high and low-pressure connections are

most likely reversed.

13) Activate your website.

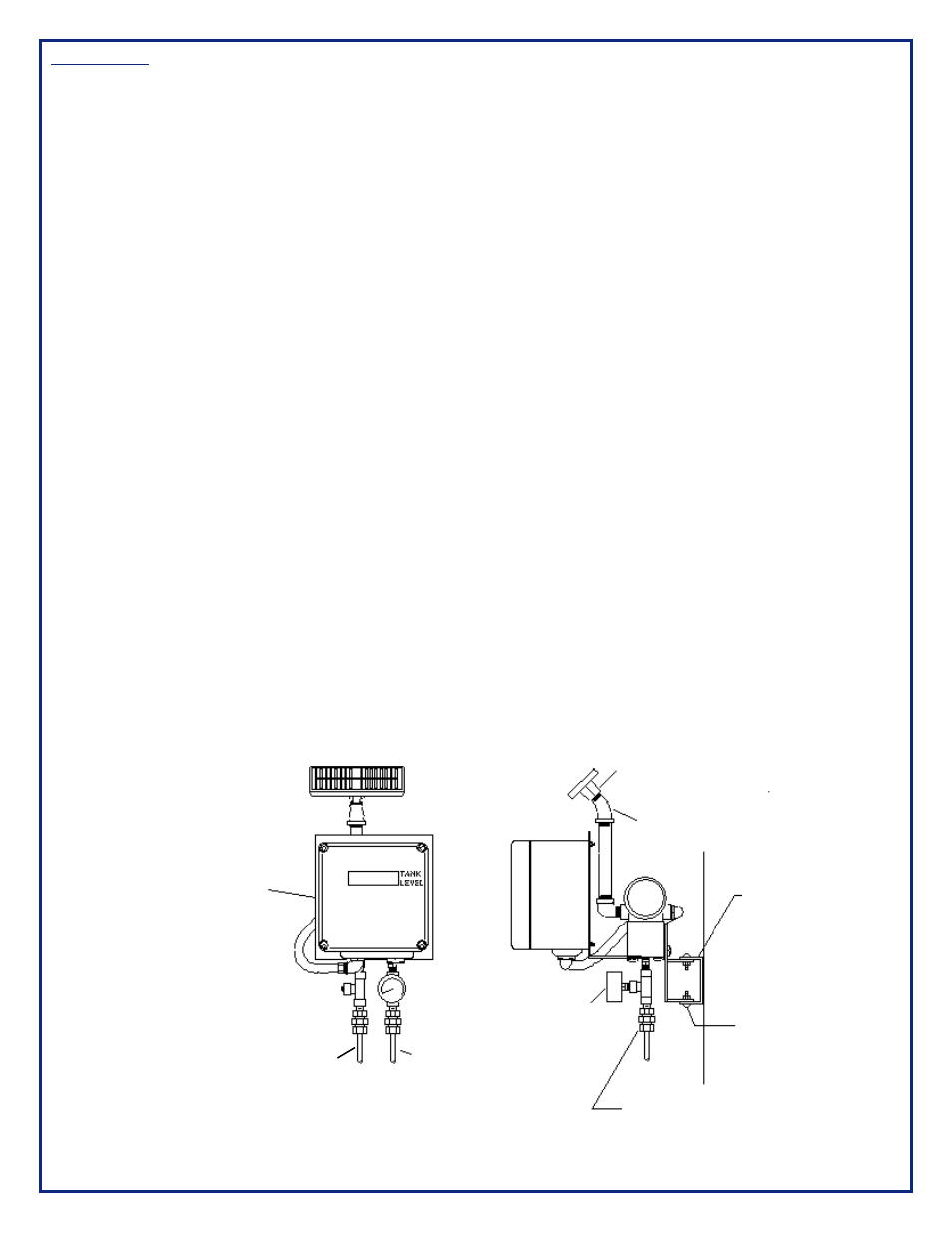

Figure 2: Typical Installation

Notes:

All supplied pressure parts are

suitable and have been cleaned for

oxygen service. All field installed

parts must have a pressure rating

equal to or higher than the tank

MAWP, be suitable for oxygen service

and likewise cleaned. See the safety

precautions in the front of this

manual.

Seal all pipe threads using Teflon tape.

Figure 2: Typical Installation

Solar Panel

45-degree Elbow

Existing Tank Bracket

Screw and Locknut

Supplied With Unit

4 Places

Tube Adapter From

Instrument Tube Size

Connecting to 0.25” FNPT

Tank

Pressure

Gauge

Low

Pressure

Tap

High

Pressure

Tap

Telemetry

Unit

6