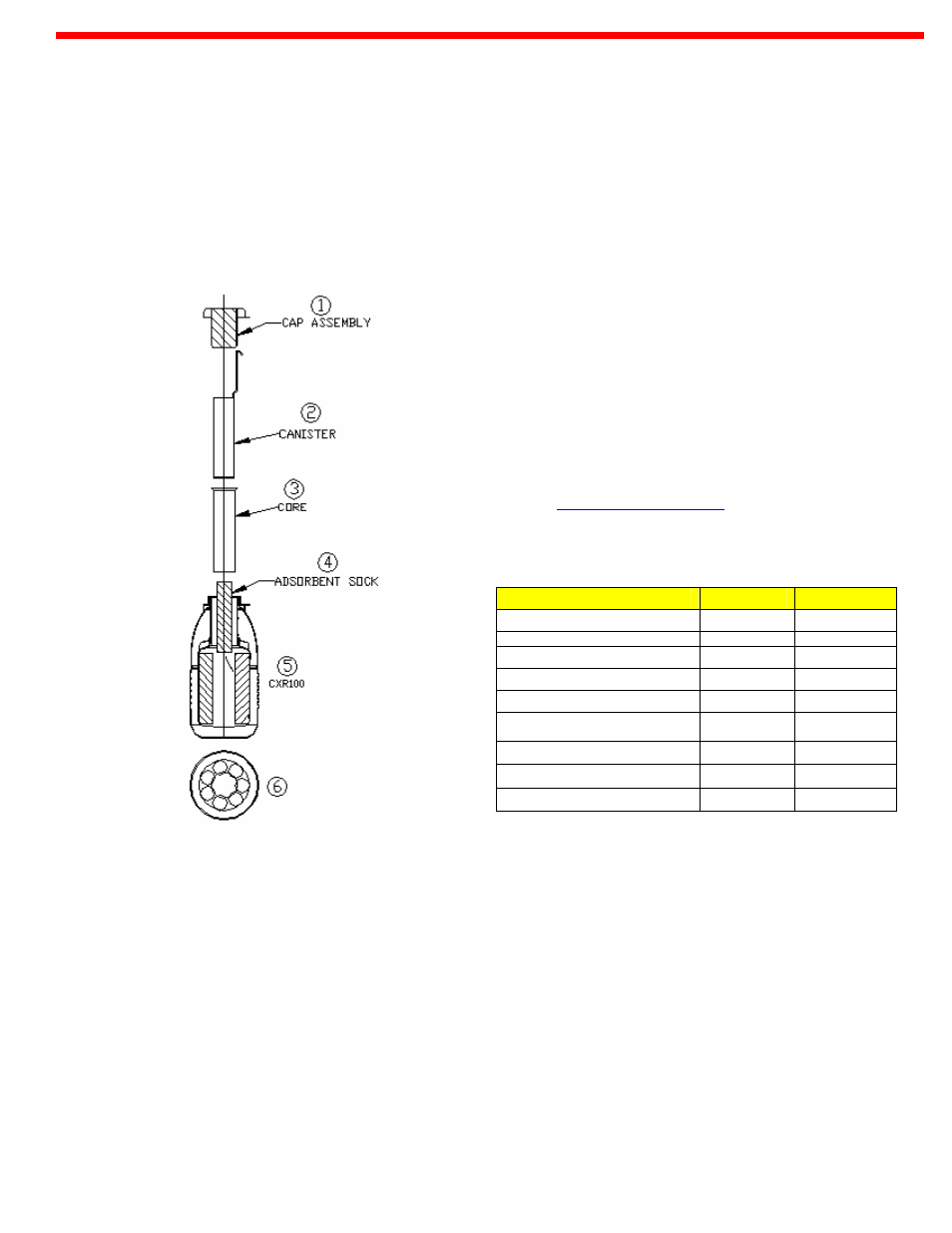

Tw-362, Figure 1.0 – Taylor-Wharton CXR500 User Manual

Page 2

TW-362

Refrigeration depends on the presence of liquid nitrogen refrigerant in

the refrigerator. Be sure to maintain a full charge of refrigerant to

prevent loss of stored materials. Please refer to the “Operations”

section of this document for instructions on the filling procedure. If you

are not able to fully charge the Cryo-Exchange unit by weight, it is

possible that moisture has accumulated in the filler material over time

with normal usage. This accumulation will result in displacement of

refrigerant. Direct dry heat not to exceed 150

o

F (65

o

C) (from a hair

dryer or other source) into the refrigerator. The unit is acceptably dry

when the tare weight is within 1 lb. (0.45 kg) of the “as received from

the manufacturer” tare weight. If the tare weight is still not satisfactory,

or contamination is suspected, a new set of adsorbent socks can be

purchased to bring the unit back to factory specifications.

REPLACING THE ADSORBENT

A)

On a clean working surface in a well ventilated area and the

CXR at ambient temperature, begin by removing the cap

assembly and canister (items 1 and 2) shown above in figure

1.0.

B)

Wearing gloves made from one of the following:

polyethylene/ethylene vinyl alcohol, polyvinyl alcohol, Teflon

or Viton, reach down the necktube and remove the core

(item 3).

C) Reach in and remove one at a time the 7 adsorbent socks

(item 4). Dispose of the used socks properly.

D) Clean the empty CXR (item 5) with an approved disinfectant,

and then dry thoroughly.

E)

Replace the Adsorbent socks with TW part number CXR100-

9C30. Place the socks down the necktube standing them

vertically around the perimeter of the CXR.

F)

Replace the Core (item 3)

G) Fill the CXR per the procedure found in the operation section

of this manual.

TRANSPORTATION

Although these refrigerators are rugged, they can be damaged if

abused or otherwise mishandled. A specially designed hard-shell

shipping container (refer to the parts section for ordering information)

should be used anytime the refrigerator is transported. This container

will help prolong the life of the unit and should be replaced if damaged

during use. When moving or transporting a refrigerator, take every

precaution to prevent sliding, tipping, bumping, or dropping the unit.

Keep the unit upright. Although there is no safety hazard if the

properly filled refrigerator is on its side, the refrigerant consumption is

much greater with the unit in this position and holding time will be

significantly reduced.

RETURNS

Manufacturing defects are covered under the containers limited

warranty. Evidence of mishandling, such as dents on the outer vessel,

or misalignment of the inner vessel, are not manufacturing defects. If

high evaporation rates are apparent under normal operating

conditions, the refrigerator may be losing its vacuum. Sweating and

the formation of frost on the outer casing are indications the

refrigerator may be losing its vacuum. All necessary steps should be

taken to protect the refrigerator’s contents. Please contact your

supplier for information on how to conduct a normal evaporation rate

(NER) test in the field.

If you would like to return goods to Taylor-Wharton for any reason, you

must first obtain a Material Return Authorization (MRA) number for

tracking purposes. Please have a description of your symptoms and

your serial number ready. Contact your supplier or call us at 1-800 TW

TANKS or

e-mail us at

.

REPLACEMENT PARTS

Description

CXR100

CXR500

Handle CXR100-6C12

N/A

Handle, Pin

8631-5000

N/A

Canister CXR100-9C24

Note*

Neckplug Assembly

CXR100-9C16 CP70-9C18

Core Sleeve

CXR100-9C20

CXR500-9C20

Adsorbent Sock (Set)

CXR100-9C30

CXR100-9C30

(2 Sets)

Decal CXR100-9C25

CXR500-9C25

Hard Shell Shipping Enclosure

CX10-8C00

CP19-8C00

Padded Carton Shipping Enclosure

3701-9277

N/A

Note*: Five shelf rack (for TW plastic box)…………RS30-9C40

Blood Bag Rack……………………………………….CP70-9C44

FIGURE 1.0