Transportation refrigeration construction – Taylor-Wharton CP Series User Manual

Page 4

Transportation

Refrigeration Construction

Although these refrigerators are rugged, they can be

damaged if abused or otherwise mishandled. A specifi-

cally designed hardshell shipping container (refer to the

parts section for ordering information) should be used

any time the refrigerator is transported. This container will

help prolong the life of the unit and should be replaced if

damaged during use. When moving or transporting a

refrigerator, take every precaution to prevent sliding, tipping,

bumping or dropping the unit. Keep the unit upright.

Although there is no safety hazard if the properly filled

refrigerator is on its side, the refrigerant consumption is

much greater with the unit in this portion and holding time

will be significantly reduced.

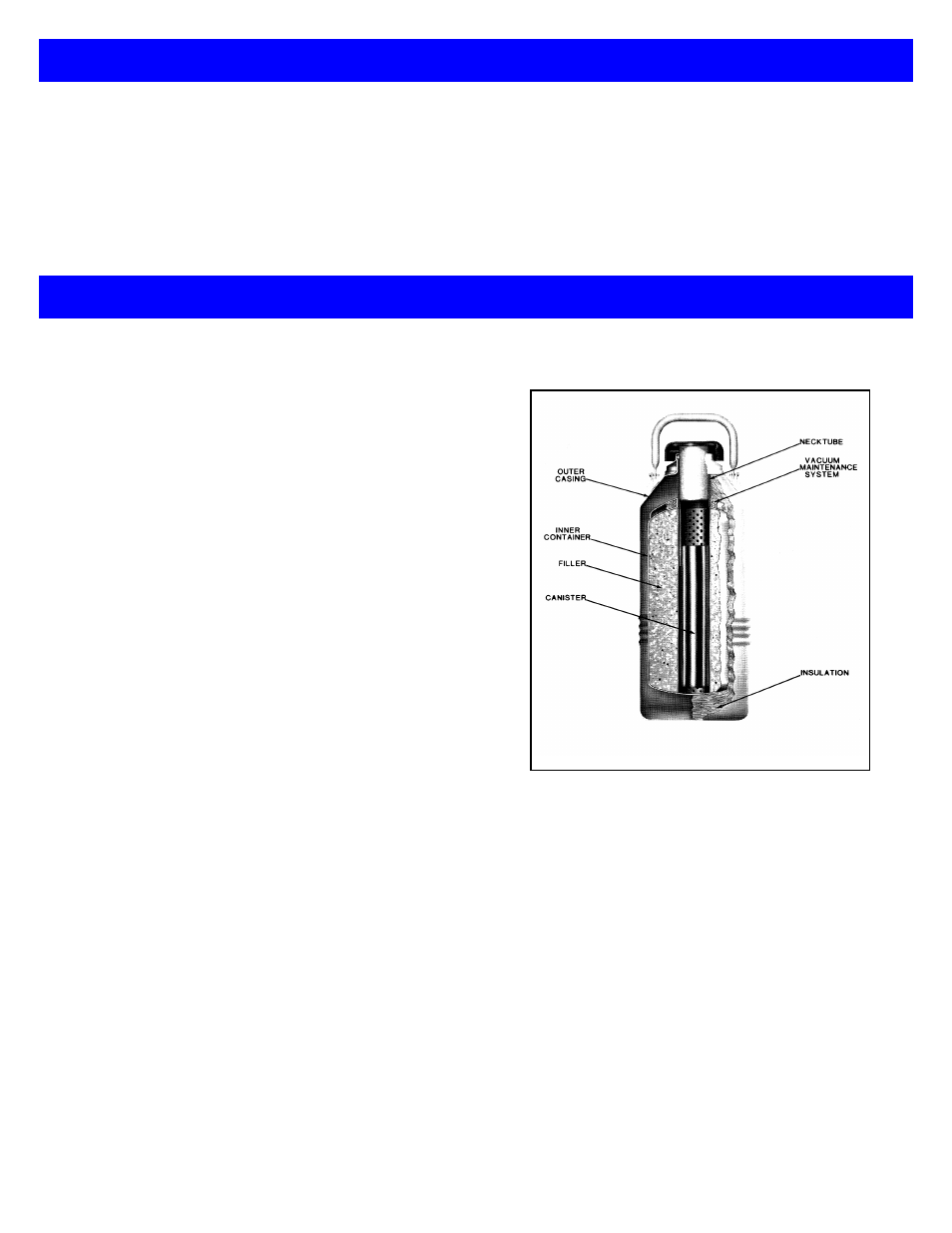

A cryogenic refrigerator is really two containers, one

within another. High technology insulation is used in

sealed vacuum space between the inner and outer

containers. The integrity of the vacuum is the key to

continued performance.

All refrigerators fail eventually. A perfect vacuum

system that does not leak cannot be achieved. Some

minute leakage of air molecules into the vacuum occurs

from moment of manufacture. A Vacuum Maintenance

System, consisting of materials that trap and hold these

molecules is built into the vacuum space to prolong the

service life of the refrigerant by many years.

The Vacuum Maintenance System can intercept these

trace leaks of air molecules only up to a point. The

vacuum will then become less efficient and the holding

time of the unit will become shorter.

The most frequent cause of vacuum failure is abuse. The

inner container as well as the weight of the nitrogen

refrigerant is supported by the necktube. A blow to the

refrigerator may cause the necktube to deform or break.

Any unit subjected to physical abuse or mishandling will

fail more rapidly than one that has been carefully

handled.