Takata Racing RACE 4 SNAP User Manual

Page 5

9

10

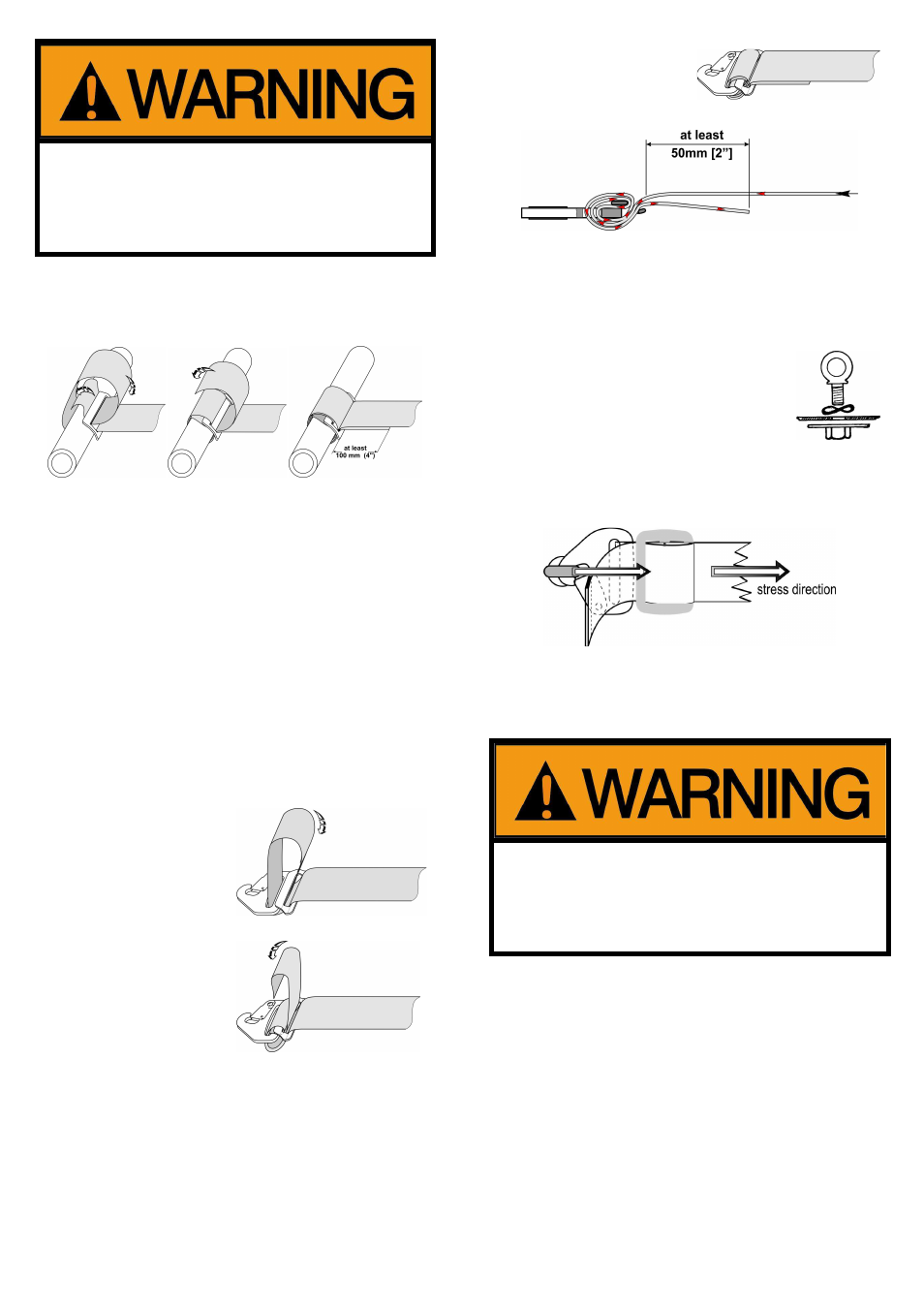

Incorrect wrap techniques or positioning 3-bar slides too far away

from the roll cage bar or from any bracket may allow webbing to

slide or slip during an accident. Extra elongation will occur which

may reduce the effectiveness of the racing harness and the Head

and Neck Support, if worn. Shoulder belts may slide off the Head and

Neck Support or will lengthen allowing the head and chest to impact

onto the steering wheel. Severe injuries or death may occur.

3. L

IGHT

W

EIGHT

D-R

ING

75

MM

(3”)

W

RAP

W

R AP P I N G

I

N S T R U C T I O N S

:

1. position D-Ring to roll bar with wider bar atop

2. slide a minimum of 600mm (24”) of strap length through D-Ring and from

underneath around roll bar [first loop]

3. slide strap from atop through D-Ring slot towards roll bar and back between

roll bar and first loop until it protrudes from slot in D-Ring (second loop).

4. Pull at shoulder belt to check that wrap will tighten when being loaded.

5. Wrap strap end around roll bar again [third loop] and thread through D-Ring

again. Shoulder belt is now sandwiched between first loop webbing and

protruding strap end.

6. Make sure strap end protrudes at least 100 mm [4”]

D - R

I N G

( L V

4 )

L

I G H T

W

E I G H T

W

R A P

S

Y S T E M T O

B

R A C K E T S

This light weight system assembles directly to 50 mm (2”) slot brackets and is

therefore commonly used by TAKATA for anti-sub strap brackets. This system is

also absolutely micro slip free.

W

RAPPING INSTRUCTIONS

1. Place LV 4 with its thicker bar onto the bracket.

2. Run strap end through slot at LV 4

and then from underneath through

webbing slot at bracket. Pull

through at least 200 mm (8”) of

webbing. Fold strap end over the

wider bar of LV 4 and back through

the gap between bracket bar and

LV 4 bar.

3. Slide strap end further through the

webbing slot at bracket and then

fold the strap end through the slot

at LV 4.

4.

Pull at the load taking strap and the bracket to make sure, the webbing is

properly clamped by the wrap hardware.

5.

If this is not achieved, check for proper strap routing and follow these

instructions step by step again.

6. If the protruding webbing is significant

longer than the minimum of 50 mm

[2”], you may fold it over again, run it

through webbing slot of the

bracket/latch and again back and

through the webbing slot at LV 4.

7.

In this case, the strap end now protrudes from the down side of the LV 4.

Webbing m ust be wrapped tightly!

E

YE

B

OLT INSTALLATION FOR

S

NAP

-O

N

B

RACKETS

•

Assemble eye bolt and spring washer as shown in sketch

beside.

•

Bolt in eye bolt and tighten securely. The optimum torque

setting is 40 Nm (350 lbs./inch). Pull either screw driver or

similar tool through eye and turn clockwise to tighten the

bolt securely.

•

Make sure the eye’s ring is pointing in direction of pull as shown in drawing

below. This position will reduce the risk of unintended loosening of the eye

bolt by torque forces applied by the harness during racing. If you cannot

achieve this position by further tightening or loosening the bolt by a maximum

of ¼ turn, dismount the eyebolt and use 2 spring washers to come closer to

the recommended position.

Safe harness belt functioning requires belt and bracket alignment

during a crash. Any restriction of the harness belt or bracket may cause

the webbing dumping/loading into bracket edges and webbing may

become cut and may cause severely injuries or death.

Never try to drill a larger bolt hole into any bracket. The bracket may be

weakened or stick to your drill bit and the bracket and attached webbing

and its hardware may spin and may cause severely injuries or death.