Takata Racing RACE 4 SNAP User Manual

Page 4

7

8

Important Information About Bolts and Torques

B

OLT

D

IAMETER

•

Stock thread holes commonly are 7/16” 20 UNF. Therefore, all TAKATA

models come with bolts and eye-bolts matching this dimension.

•

For all other dimensions you must provide the correct bolt diameter, type of

thread and bolt length. USE ONLY bolts grade 8.8 and higher.

•

Never use bolts of the wrong diameters or bolts that are too short

and may allow the bolts to become loose and separate from the

anchorages. Use of improper bolts will cause the racing harness

to fail.

•

Never use bolts that are too long and may intrude into the fuel

tank or other parts of the car.

•

Always tighten bolts with the proper torque. Improperly

tightened bolts may loosen during harness belt use and may

become separated during a crash.

•

Never over-tighten bolts. Over-tightening bolts may destroy the

thread and allow the bolt to separate during a crash.

•

BOLT FAILURE MAY RESULT IN SEVERE INJURIES OR DEATH.

Never try to drill a larger bolt hole into any harness belt bracket.

The bracket is not designed for modifications and may stick to

your drill bit and the bracket and attached webbing and its

hardware may spin and may result in severe injuries or death.

T

I G H T E N I N G

T

O R Q U E S B Y

B

O L T

D

I M E N S I O N

•

Each bolt diameter and type of thread requires an individual torque for proper

tightening. The torque as listed below is defined by national or international

standardisation organisations.

•

For safe installation always tighten bolts to the recommended torque.

•

For any installation use e.g. “Loctite 243” or spring washers where

recommended to secure bolt fastening.

M 8

5/16”

M 10

3/8”

7/16”

20 UNF

15/32”

1/2”

Torque

in Nm

25

25

50

50

40

87

113

Torque

in lbinch

18,5

18,5

37

37

30

64,5

83,5

C

REATING A NEW ATTACHMENT POINT

•

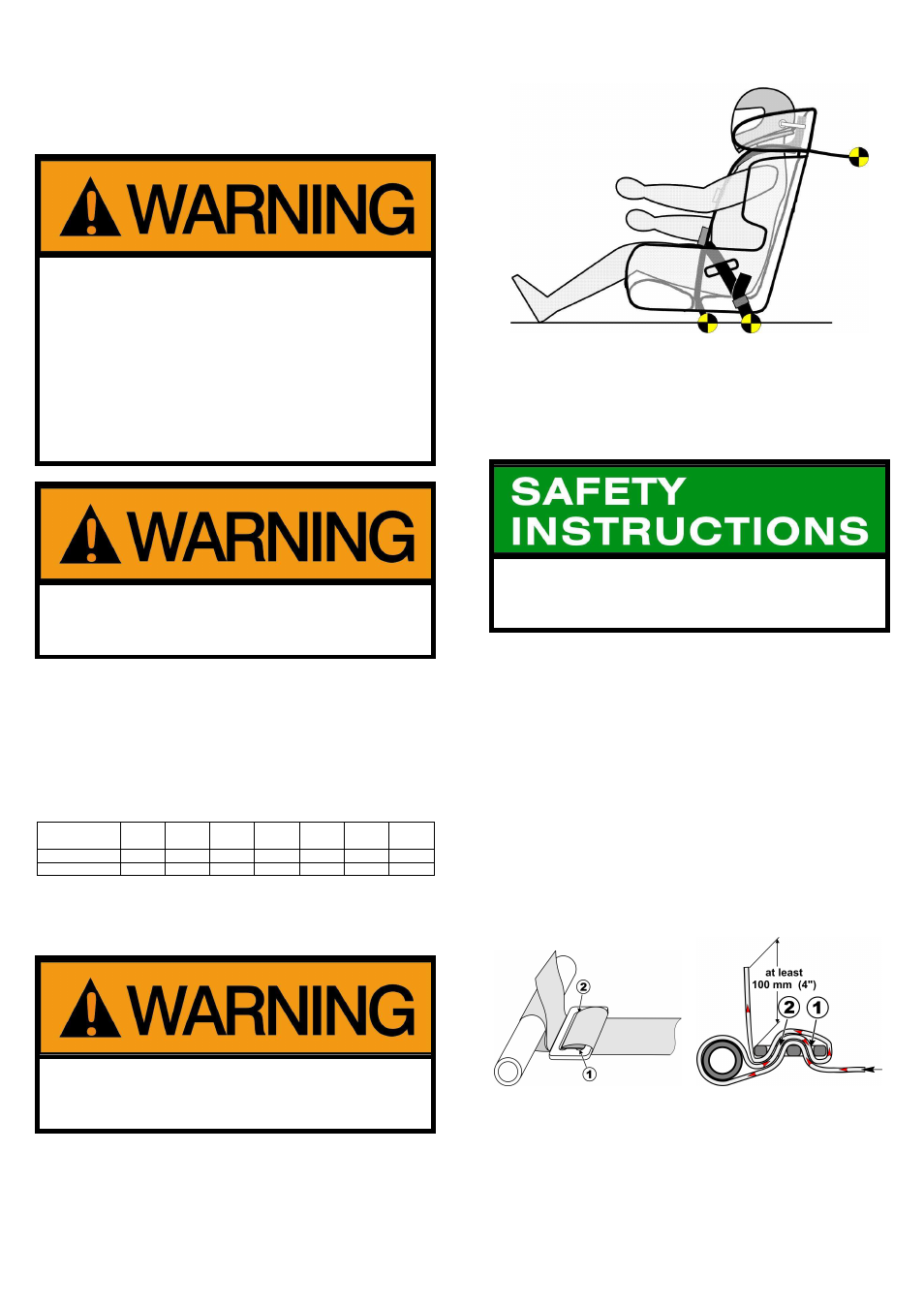

For new attachment points to the chassis heed the following WARNING box.

If you intend to drill a hole, make sure not to damage the fuel tank,

fuel lines, electrical wires, brake lines or other important

components. Any damage to such components can result in fire or

explosion and severe injuries or death can result.

•

For new attachment points to the chassis you must use a FIA specified

reinforcement plate [see list of accessories in TAKATA catalogue].

•

Drill a hole of 12 mm [15/32”] diameter for lap- & shoulder belt and 5-point

anti-sub strap attachments.

•

Use with this product supplied bolts and eyebolts only! They are tested for

quality and fit to the threads provided by the TAKATA reinforcement plate and

to the brackets.

I

N I T I A L

R

E S T R AI N T

A

D J U S T M E N T D U R I N G

I

N S T AL L AT I O N

While first installing your racing harness the following items may require minor

adjustments to the belts.

•

Shoulder belt tilt lock adjusters must be positioned minimum of 250 mm

(10”) below the collar bone or lower if possible.

•

If a Head and Neck Support is worn, the adjuster must be positioned low on the

yoke end of the Head and Neck Support.

•

Lap belt tilt lock adjusters must not be positioned within the openings of the

seats. Adjusters must be either outside of the seat at a minimum distance of

40 mm (1.5”) from the opening or close to the rotary buckle inside the seat.

Any drilled hole for racing harness attachment must be strengthened by a

reinforcement plate meeting FIA specification

TAKATA recommends, whenever possible and suitable, the use of existing

factory provided anchor points for the lap- and shoulder belts.

1. W

RAP

S

YSTEMS TO ROLL BAR INSTALLATION AND

BRACKETS ASSEMBLY

2. 3-

BAR SLIDE WRAP

This installation is commonly used for

•

shoulder strap roll cage installation and

•

to assemble open strap ends to brackets or approved harness hardware.

Do not install a lap belt directly to a roll cage by wrap around technique.

Racing harness with end brackets assembled to the shoulder belts by a 3-bar

slide allow to dismount the brackets and use the 3-bar slide for wrap around

installation directly to the roll cage. Also brackets can be exchanged e.g. from a

snap-on to a bolt-in bracket or vice versa.

I

N S T A L L A T I O N