Gas line pipe sizing, Gas pressure check – CFM UVHK31MP User Manual

Page 12

12

20008056

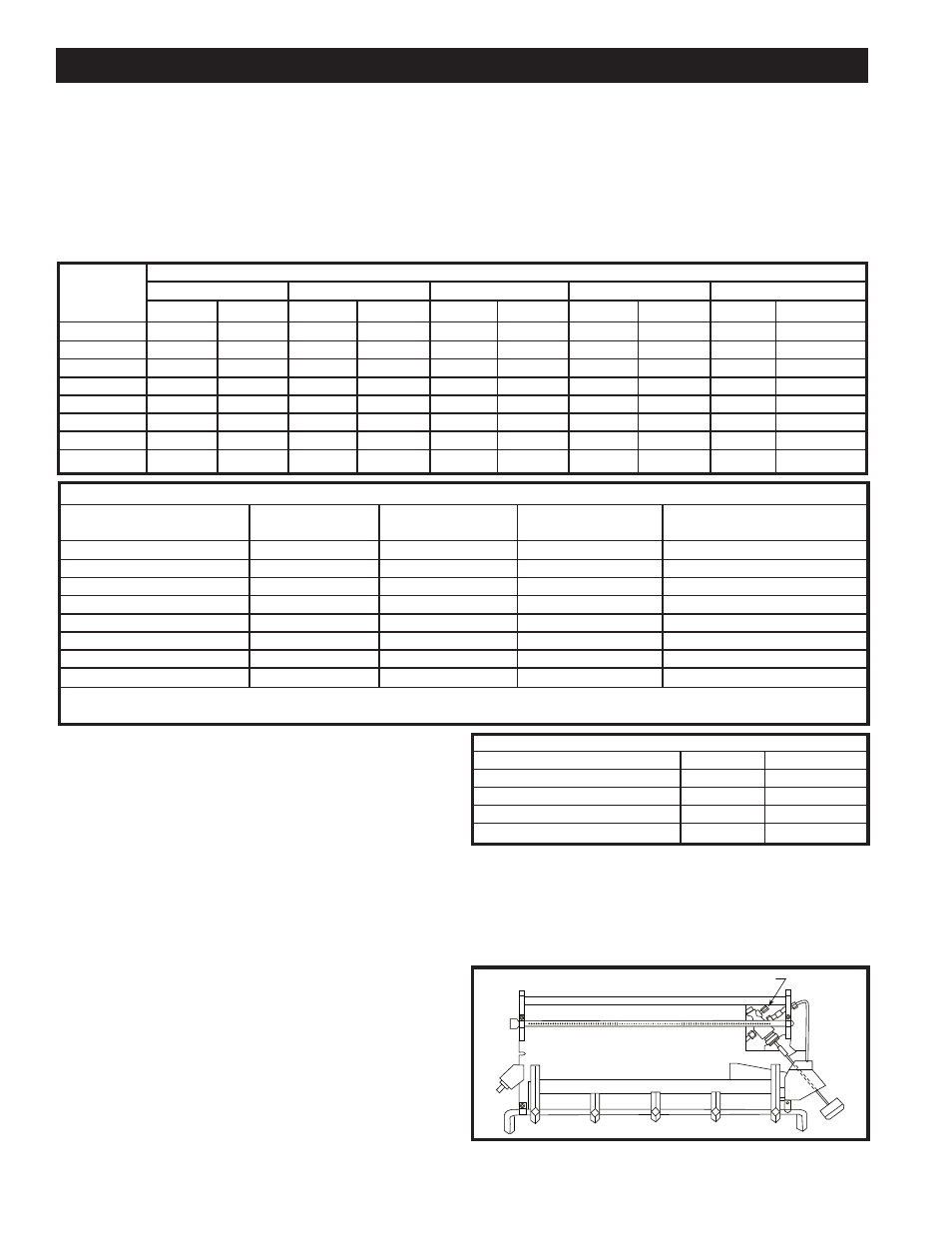

NOTE: To determine the size of the branch gas line from the main gas line to the fireplace, enter the tables below (for

iron pipe or copper tubing) using the distance from the gas meter or second stage regulator to the furthest appliance on

the gas system. Select a pipe or tube diameter which has enough capacity to meet the maximum input requirement of

the fireplace. Regardless, do not use less than 1/2” diameter for the branch line. For any distances required longer than

shown in these tables, refer to the National Fuel Gas Code.

NOTE: There may be a local gas utility requirement specifying a minimum diameter for gas piping. All units require a 1/2 inch pipe con-

nection at the gas valve.

Gas Line Pipe Sizing

CAPACITY OF PIPING

Cubic Feet per Hour based on 0.3” w.c. Pressure Drop

Specific Gravity for Natural Gas - 0.6 (1000 BTU/Cubic Foot)

Specific Gravity for Propane Gas - 1.6 (2550 BTU/Cubic Foot)

Gas Pressure Check

Check the inlet pressure to the appliance to ensure that it is as

shown in Table 1. Also check the incoming gas pressure where

the field installed gas line connects to the gas logs.

The manifold pressure is controlled by the regulator and should

be checked at the pressure test point located downstream from

the regulator on the control valve body. Access to the pressure

test point is obtained by removing all logs and the heat shield

on the right hand rear side of the base. The pressure test point

1/8” NPT plugged tapping is located on the rear face of the

control body. (Fig. 5)

The pressure should be checked with the appliance burning on

high (highest setting) and all other gas appliances turned on.

One must then read the manometer and if pressures are not

10” w.c. for LP or 3.5” w.c. for natural gas, then the inlet pres-

sure must be adjusted or increased until the proper pressures

are attained. If these pressures are greater than 10” w.c. for

LP or 3.5” w.c. for natural gas, contact your gas supplier before

operating the appliance.

The pressure regulator is preset and locked to prevent tamper-

ing. If the pressure is not as specified, replace the regulator

with part # 73332 (for natural gas only), or part # 73333 (for L.P.

gas only).

CAUTION: If the appliance’s operating pressures are not

checked and adjusted, improper combustion may result in soot

being produced.

After measuring the pressure, replace the test point plug and

check for leaks. Replace the control box cover and the two

phillips head screws.

Length

Nominal Inches for Iron Pipe Sizes (1,000s BTU/hr)

of

1/2” D

3/4” D

1” D

1¹⁄₄” D

1¹⁄₂” D

Pipe

Natural Propane Natural Propane Natural Propane Natural

Propane Natural Propane

20’

92

143

190

296

350

546

730

1135

1100

1711

30’

73

115

152

237

285

444

590

918

890

1385

40’

63

97

130

202

245

380

500

778

760

1183

50’

56

87

115

179

215

334

440

683

670

1043

60’

50

79

105

163

196

304

400

622

610

949

70’

46

71

96

151

180

280

370

576

560

872

90’

40

61

84

130

160

250

320

497

490

763

100’

38

59

79

122

150

235

305

474

460

717

Outside Diameter Copper Tubing, Type L (1,000s BTU/hr)

Tubing Length

1/2”

5/8”

3/4”

7/8”

Feet

0.43

0.545

0.666

0.785

10

110

206

348

536

20

76

141

239

368

30

61

114

192

296

40

52

97

164

256

50

46

86

146

224

60

42

78

132

203

80

36

67

113

174

100

32

59

100

154

WARNING: Use only internally tinned copper tubing. If correct copper tubing is not used, tubing can deteriorate and develop

gas leaks.

T126

Test point

10/29/03 djt

Table 1

Gas Inlet Pressure

Natural

Propane

Max.

10.5” w.c.

13” w.c.

Normal

7” w.c.

11” w.c.

Min.*

5.5” w.c.

11” w.c.

Regulator Pressure

3.5” w.c.

10.0” w.c.

*Minimum inlet supply pressure for the purpose of input adjustment.

Test Point

T126

Fig. 5 Pressure test point.