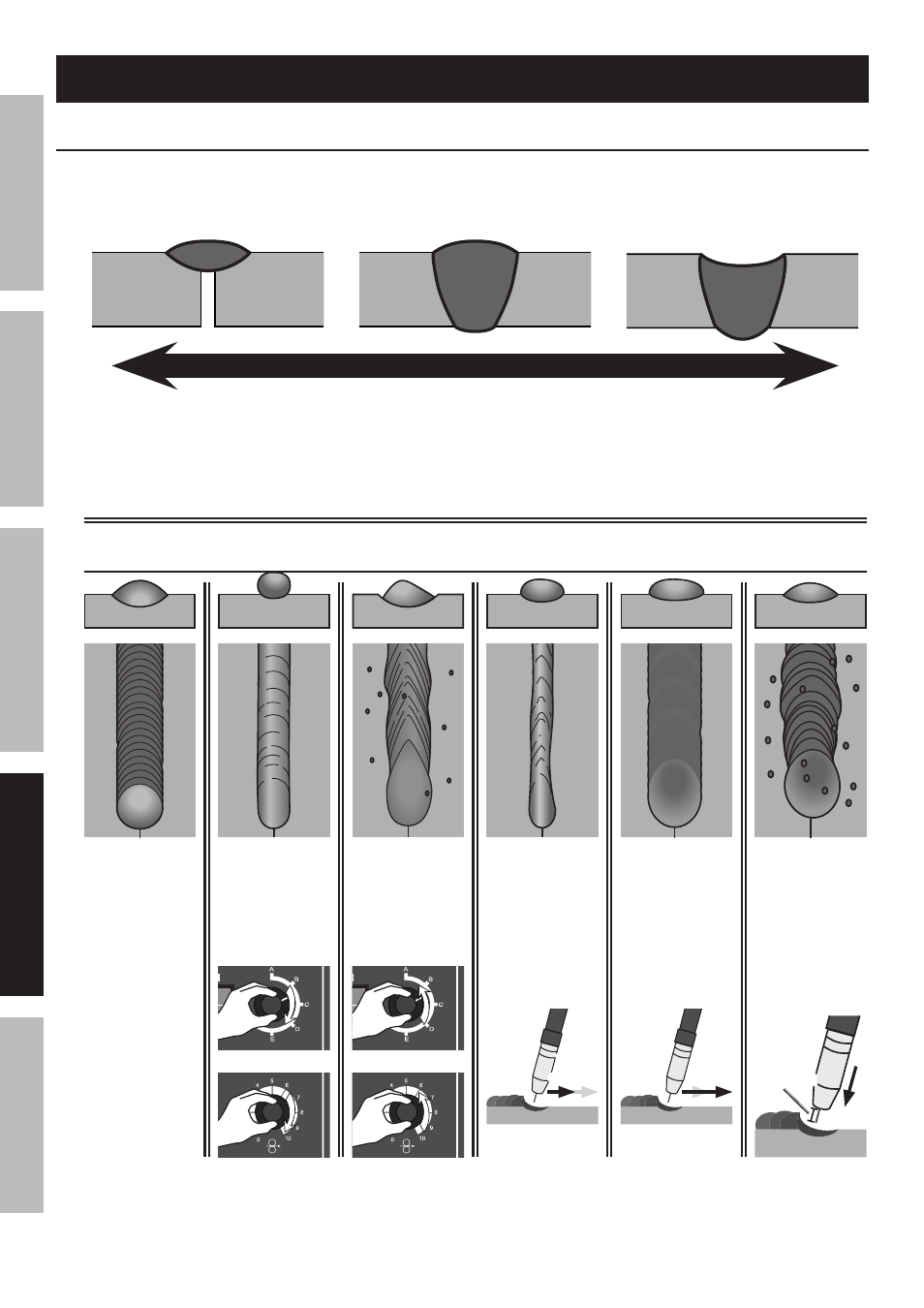

Workpiece heat control / weld penetration, Example weld diagrams, Weld diagnosis – Chicago Electric MIG 180 Wire Feed Welder 68886 User Manual

Page 24: How to reduce workpiece heat and limit penetration

Page 24

For technical questions, please call 1-800-444-3353.

SKU 68886

EXCESS PENETRATION OR

BURN-THROUGH

PROPER PENETRATION

INADEQUATE PENETRATION

Not hot enough

Too hot

Ideal heat

Weld Diagnosis

Workpiece Heat Control / Weld Penetration

Good

Weld

Current

Too Low or

Wire Feed

Too Slow

Current

Too High or

Wire Feed

Too Fast

Weld Speed

Too Fast

Weld Speed

Too Slow

Stickout

Too Long

or Wrong

Polarity

Example Weld Diagrams

TO CORRECT:

weld

slower

TO CORRECT:

weld

faster

How to increase workpiece heat

and increase penetration:

(to weld THICKER workpieces properly)

How to reduce workpiece heat

and limit penetration:

(to weld THINNER workpieces properly)

a.

Increase weld current

b.

Weld more slowly

c.

Use faster wire feed

d.

Use shorter stickout

a.

Decrease weld current

b.

Weld more quickly

c.

Use slower wire feed

d.

Use longer stickout

TO CORRECT:

or

MIG 180

WIRE FEED WELDER

ITEM 68886

WIRE FEED SPEED

240V~

I

O

MIG 180

WIRE FEED WELDER

ITEM 68886

WIRE FEED SPEED

240V~

I

O

TO CORRECT:

or

MIG 180

WIRE FEED WELDER

ITEM 68886

WIRE FEED SPEED

240V~

I

O

MIG 180

WIRE FEED WELDER

ITEM 68886

WIRE FEED SPEED

240V~

I

O

TO CORRECT:

maintain

less

than

1

/

2

″

stickout

Check Polarity

and

SAFETY

MAINTENANCE

BASIC WELDING

WELDING TIPS

SETUP