Vermont castings vcbvtn/tp & vcpvtn/tp room heater – Vermont Casting VCBV30TP - 30 User Manual

Page 6

6

Vermont Castings VCBVTN/TP & VCPVTN/TP Room Heater

Connect to Gas Supply

Before connecting the appliance, turn of all gas appli-

ances. Close the main gas valve at the gas meter or Lp

tank. Make certain there is good ventilation where the

installation will be made. Installation should comply with

all applicable building codes and ANSI Z223.1, latest

edition. Use LP gas resistant pipe compound to seal

threaded joints.

An installer supplied, design certified gas pressure

regulator must be installed to bring the gas supply

pressure down to 14” w.c.

WARNING: Never connect an unregulated gas line

to the heater.

IMPORTANT: Check gas line pressure before connect-

ing heater to gas line. Gas line pressure must not be

higher than 14” w.c. If gas line pressure is higher,

heater gas pressure regulator damage could occur.

NOTE: The gas line connection can be made with 3/8”

black or steel pipe. Internally tinned copper tubing may

be used in certain areas. Check your local codes. Use

pipe of large enough diameter to allow proper gas

volume to heater. If pipe is too small, undue pressure

loss will occur.

CAUTION: Use pipe joint sealant that is resistant to

liquefied petroleum gases.

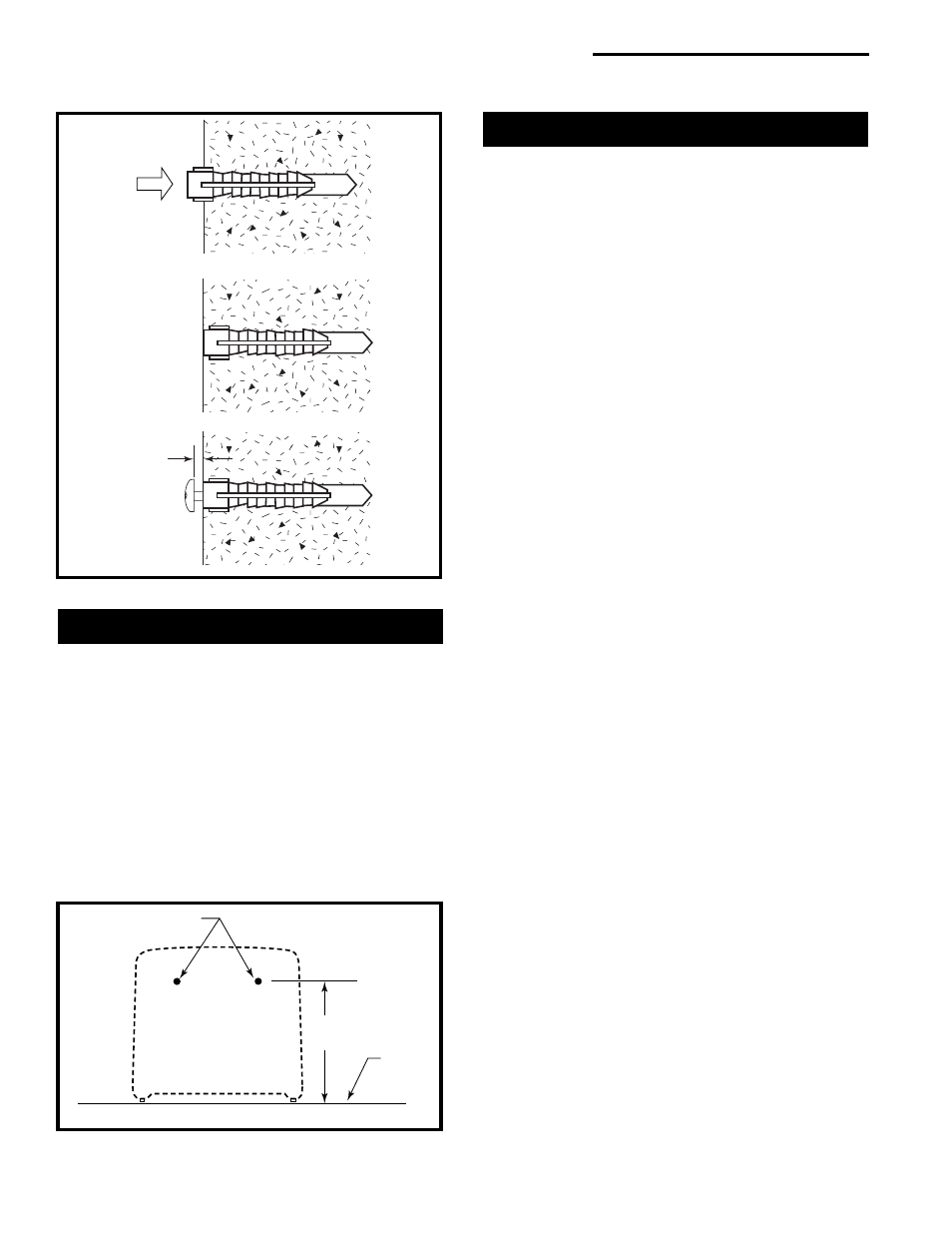

Install sediment trap in supply line as shown in Figure 6.

Locate sediment trap where it is within reach for

cleaning. Locate sediment trap where trapped matter is

not likely to freeze. A sediment trap prevents moisture

and contaminants from going into the heater controls. If

the sediment trap is not installed or is installed wrong,

the heater may not operate properly.

Test for gas leaks with a mild soap and water solution.

Apply water/soap solution with brush only -

do not over

apply. NEVER test with an open flame.

Floor Installation

1. The heater may only be installed on a noncombus-

tible flat surface. Wall mounting screws may be used

to keep heater from side movements.

2. Measure heater mounting screws location “X” as

desired above floor. (Fig. 5)

3. Use enclosed “paper template” for proper distance

between holes. Be sure template is level. It may be

necessary to use plastic or lead anchors for plaster

wall.

4. Drill holes at marked locations using 9/64” drill bit.

5. Leave screw head out from wall far enough to

attach heater.

X

Screw Holes

Floor

RH107

Fig. 5 Optional wall mounting screw for floor installation.

1/16"

(1.6mm)

RH102

Fig. 4 Wall anchor.