Troubleshooting – Harbor Freight Tools Model 99792 User Manual

Page 14

SKU 99792

For technical questions, please call 1-800-444-3353.

Page 14

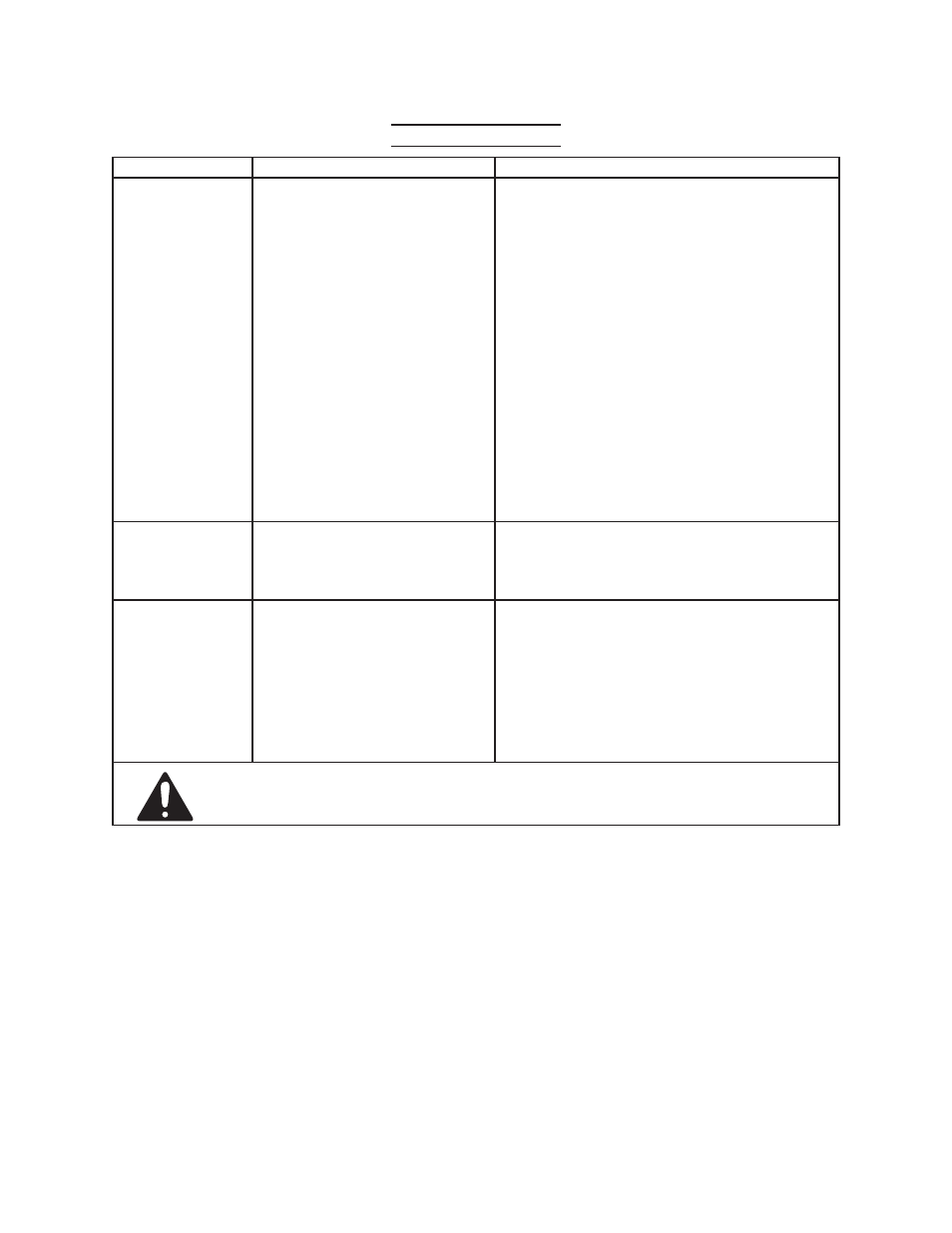

Troubleshooting

Problem

Possible Causes

Likely Solutions

Decreased output.

1. Not enough air pressure and/

or air flow.

2. Obstructed trigger.

3. Incorrect lubrication or not

enough lubrication.

4. Blocked air inlet screen (if

equipped).

5. Air leaking from loose housing.

6. Mechanism contaminated.

7. Chisel edge is damaged.

1. Check for loose connections and make sure

that air supply is providing enough air flow

(CFM) at required pressure (PSI) to the

tool’s air inlet.

Do not exceed maximum air

pressure.

2.

Clean around trigger to ensure free

movement.

3. Lubricate using air tool oil and grease

according to directions.

4. Clean air inlet screen of buildup.

5. Make sure housing is properly assembled

and tight.

6. Have qualified technician clean and lubricate

mechanism. Install in-line filter in air supply

as stated in Initial Set Up: Air Supply.

7. Replace with a new chisel do not sharpen.

Housing heats

during use.

1. Incorrect lubrication or not

enough lubrication.

2. Worn parts.

1. Lubricate using air tool oil and grease

according to directions.

2. Have qualified technician inspect internal

mechanism and replace parts as needed.

Severe air

leakage.

(Slight air leakage

is normal,

especially on older

tools.)

1. Cross-threaded housing

components.

2. Loose housing.

3. Damaged valve or housing.

4. Dirty, worn or damaged valve.

1. Check for incorrect alignment and uneven

gaps. If cross-threaded, disassemble and

replace damaged parts before use.

2. Tighten housing assembly. If housing cannot

tighten properly, internal parts may be

misaligned.

3. Replace damaged components.

4. Clean or replace valve assembly.

Follow all safety precautions whenever diagnosing or servicing the

tool. Disconnect air supply before service.