FASS T D10 125G User Manual

Page 11

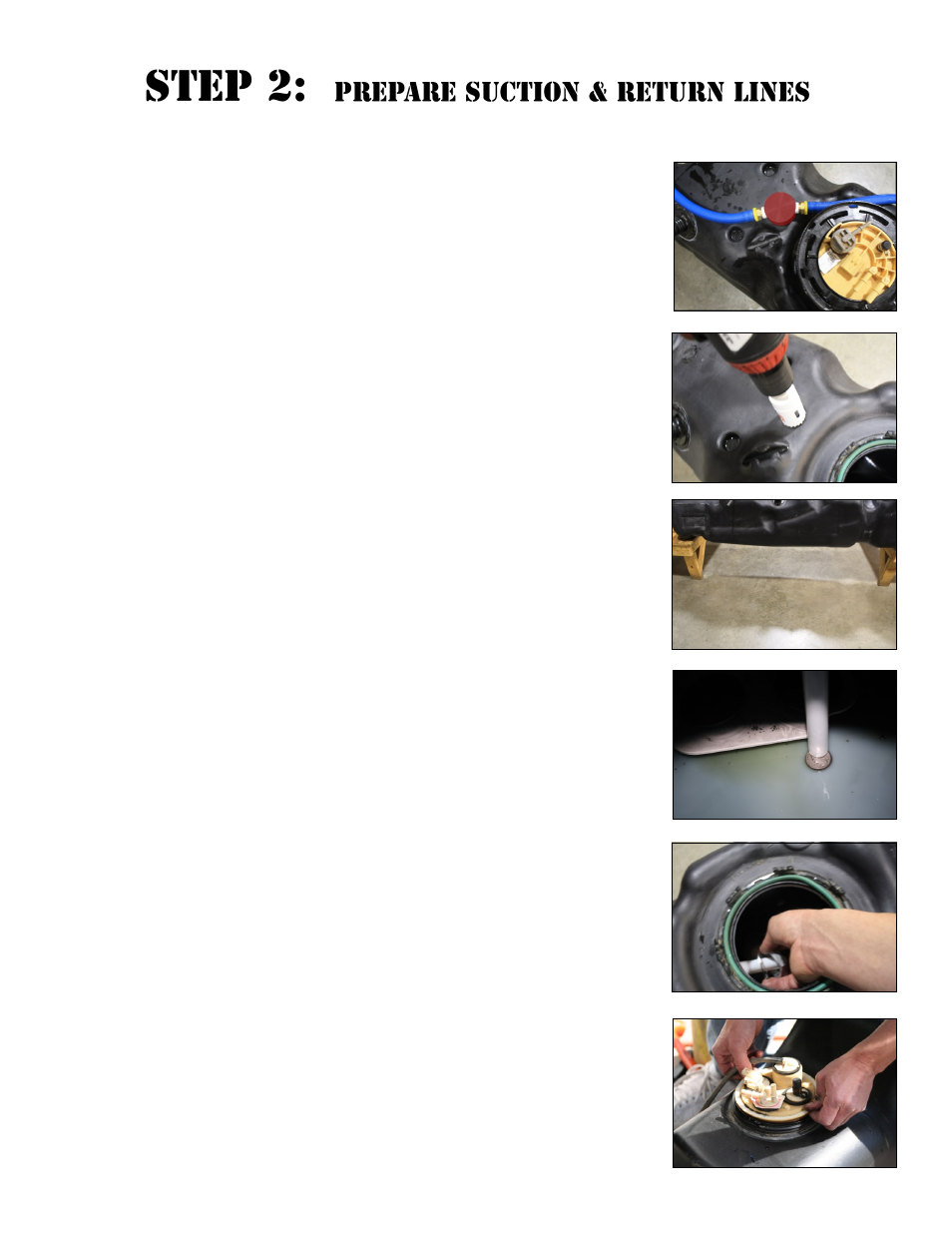

M.

With proper length being obtained, place the assembly into the drilled

hole securing the assembly using the lock washer & nut. Loctite may be

applied to the threads of the BHF-1002 for added insurance.

J.

Drill a 1 3/8” hole, catching all debris. De-bur hole and remove any

missed debris in the fuel tank.

K.

VERY IMPORTANT:

Support fuel tank on both ends allowing the natu-

ral formation of the tank to take place. Failure to perform this step can

and will create an issue with less usable fuel!

L.

Place the bulk head assembly into the drilled hole, take measurements so

the bottom of the suction tube is only 1/8” (no more than 2 quarters

stacked) from the bottom of the fuel tank. Using a razor knife make mul-

tiple cuts to insure proper length, it is easy to shave the suction tube with

the razor. It is more efficient to cut the tube too long and then correct

to proper length than it would be to cut too short.

I.

Before drilling marked location, clean area of debris. Using the photo,

double check area selected for any interference including the fuel level

arm.

N.

Carefully reinstall install pick up module making sure the leveling arm is

not obstructed by the suction tube. Reinstall factory lock ring. Reconnect

factory wire harness and factory fuel lines