FASS T D08 260G User Manual

Page 16

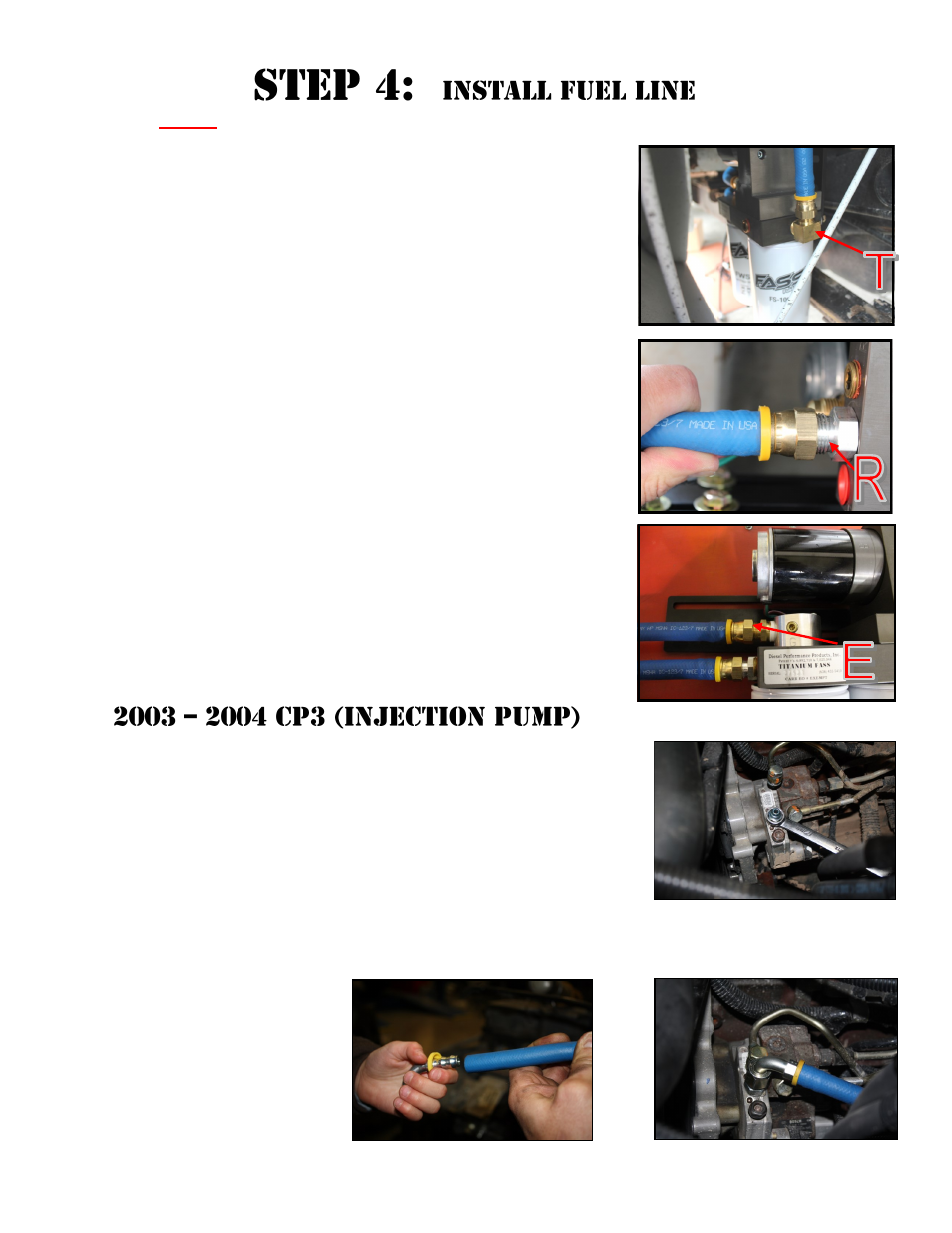

D.

Disconnect factory fuel line from inlet side of the factory injection

pump, Install the DIPF-1003 fuel fitting into this inlet port. (Note:

This is where the suction fuel line from the fuel filter enters the injec-

tion pump.)

E.

Measure and cut fuel line. Insert PL-2003 90° Push-Lok fitting using oil. Install fitting onto DIPF-

1003. Torque to 18 ft/lbs.

Note: Secure all fuel lines with cable ties. Cable ties are an economical way to prevent the

possibility of problems occurring!

A.

Route suction line from the suction tube assy. to port ‘T’ on the

FASS system. Cut FL-1058 to needed length. Insert PL-1058 using

oil. Connect to 10-302 in port ‘T’. Torque to 18 ft./lbs.

B.

Route fuel line from the ‘R’ fitting of the suction tube assembly to

the ‘R’ port on the FASS system with a gentle bend. Cut and insert

the PL-1005 fitting to the hose. Use oil. Attach fitting to the ‘R’ port.

Torque to 18 ft/lbs.

C.

Insert PL-1005 in remaining fuel line. Connect to the ‘E’’ port of

the FASS system. Use oil. Torque to 18 ft./lbs. Route this line up to

the injection pump.

Caution: Do not use sealant on AN fittings. Only use sealant on threads going into the FASS pump.

NOTE: Hose clamps are not recommended for push lock fittings

and can damage the strength of hose. They will hold up to

300psi! Use oil on fittings and inside fuel line when installing

Push-Lok fittings