Dynalco SPD-100L Tachometer User Manual

Calibration instructions

If necessary, turn to the reverse side of this card

to calculate Signal Frequency and Gate Time.

SPD-100 and SPD-100L

Signal-Powered Tachometer

Calibration Instructions

The SPD -100 and SPD -100L tachometers are normally factory-

calibrated to the customer-specified number of sensing teeth or

discontinuities, sensing speed, and desired numerical display.

To calibrate an SPD-100 or SPD-100L

1. Remove the sealing plug on the back of the housing.

2. Apply the calculated signal frequency to terminals 1 and 2.

A Dynalco F-16 or F-15 signal generator is ideal.

3. Select the appropriate gate time range on the 4-position

switch.

See label on back of SPD-100 or SPD-100L; or Item 3,

reverse side of card.

4. Adjust the vernier potentiometer for the desired display.

See below

.

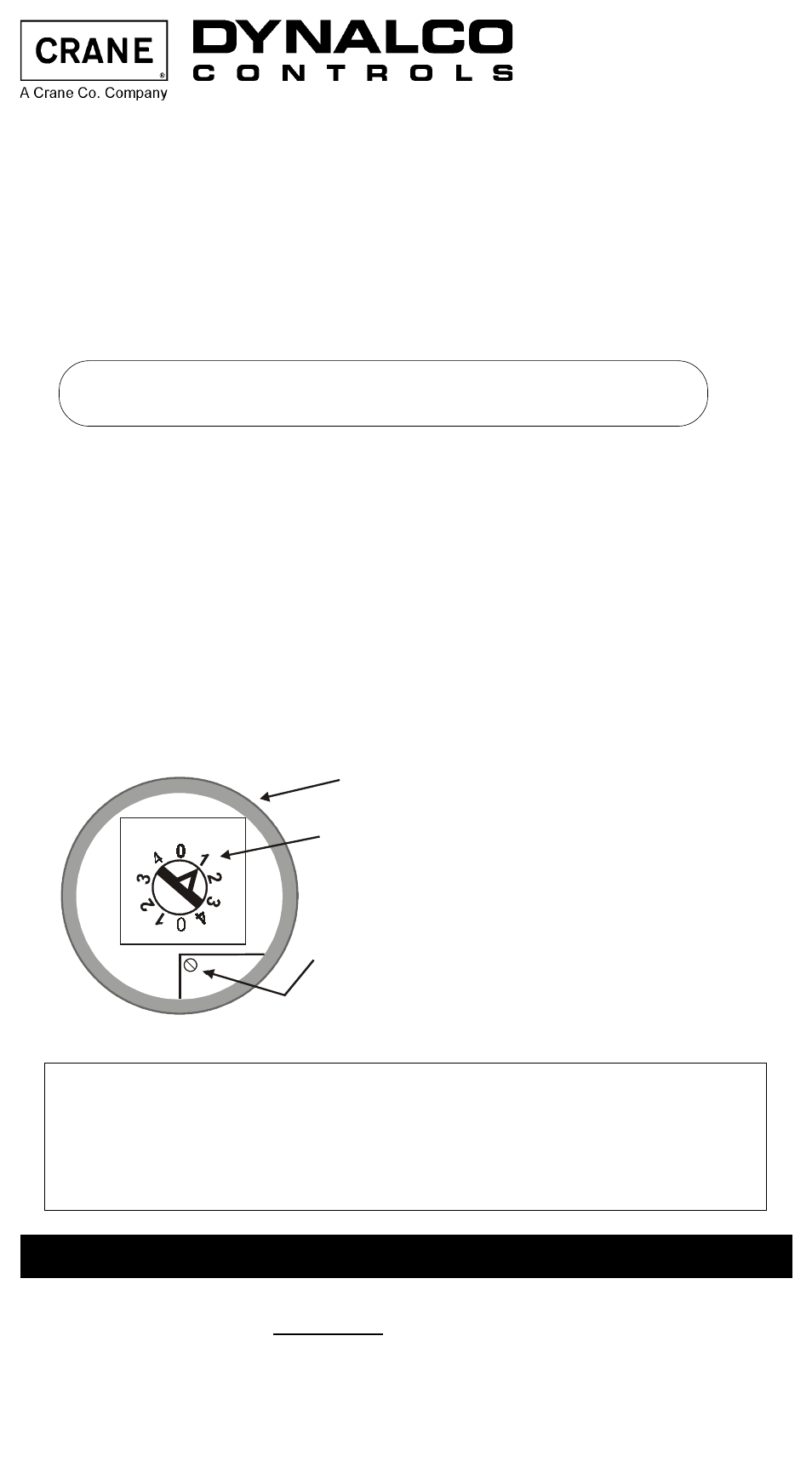

Shown with sealing plug removed

4-position switch

Vernier potentiometer

[clockwise to increase display reading;

counterclockwise to decrease]

© 2002 Dynalco Controls

145F-12040, Rev. 0

(For example: 60 /113 teeth = 0.53 sec. gate time)

QUICK

GATE TIME

CALCULATION

}

60

Number of

Teeth

Assumes the pickup is “seeing” the

gear of interest directly, not through

a step up or step down ratio

.

{

See label on back of SPD-108, SPD-108L for additional information

Example:

If 3390 Hz = 1800 RPM, then gate time is 0.53 seconds.

1. Apply 3390 Hz to terminals 1 and 2 on tachometer (no polarity).

2. Turn the gate time range switch to (either) position number 1 to

select gate time range of 0.26–0.72 seconds.

3. Adjust the vernier potentiometer to obtain a display of 1800.