Dynalco PG-100 Pulser User Manual

Pg-100, Rpm pulser, Year warranty

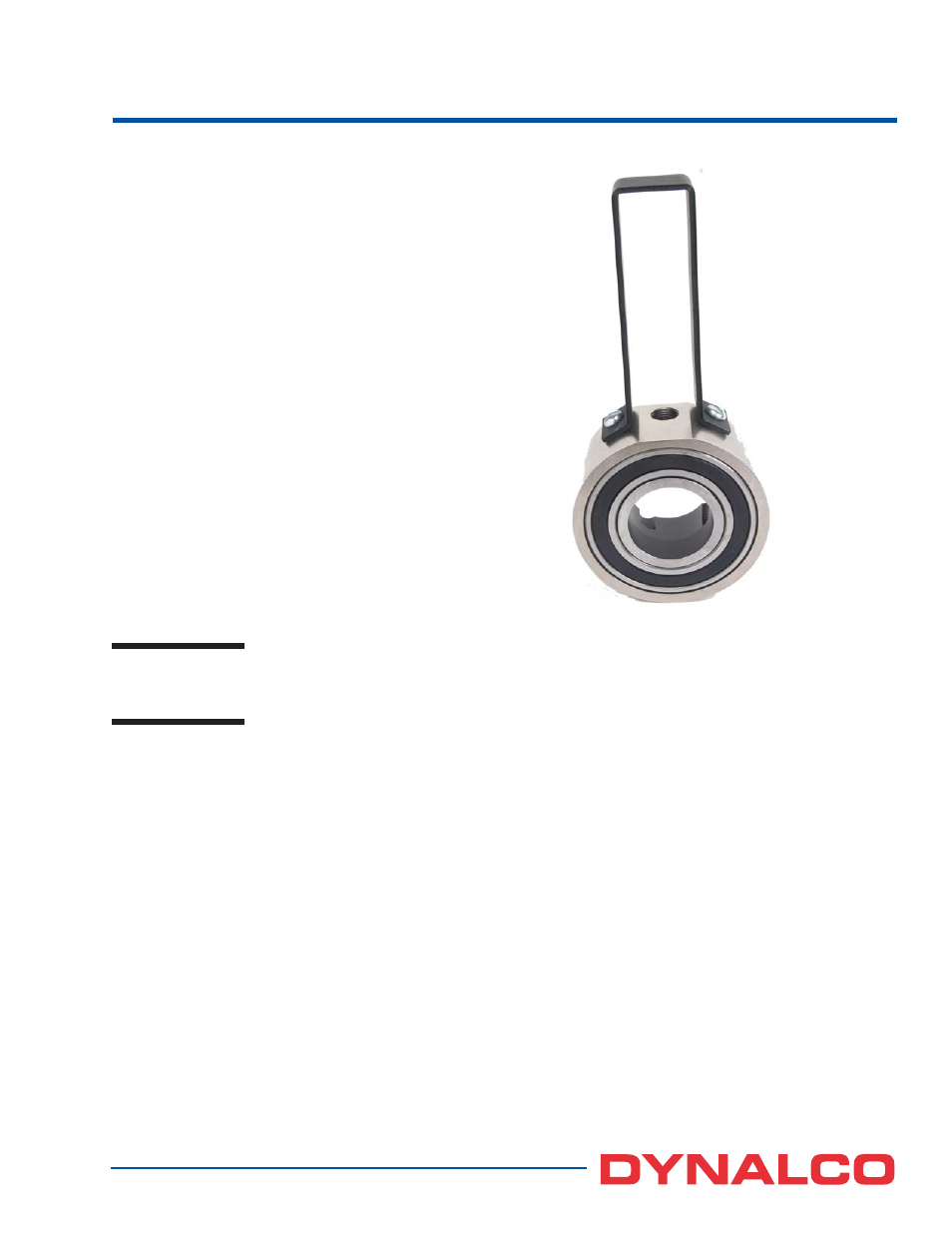

PG-100

RPM Pulser

2-Year

Warranty

Product Data Sheet

March 2009

Instrumentation & Controls

Converts Shaft Rotation

into Signal Frequency

FEATURES

The PG-100 can be used when a gear is not

available on the shaft to generate a signal frequency

from a magnetic pickup, or when it is more convenient

to slip on theis transducer than to mount a gear or

sprocket with associated bracket to hold the

magnetic pickup with appropriate spacing.

Thre are 60 gear teeth on the rotor inside the PG-

100. The gear teeth face the pole piece of the

magnetic pickup mounted on the fixed-position

outer ring. The pickup guard is positioned against a

fixed surface to prevent movement of the outer ring.

As the shaft rotates, a signal frequency, numerically

equal to rpm, is generated by the pickup. The

waveshape of the output voltage is approximately

sunusoidal.

The PG-100 RPM Pulser provides an

output frequency directly proportional and

numerically equal, in Hz, to the RPM of

the shaft on which it is mounted. No

external power required. Shaft diameters

from 1/2 inch to 1-1/4 inches, in increments

of 1/16 inch, can be accommodated. The

PG-100 develops a signal frequency used

with Dynalco’s electronic tachometers,

other totalizers, frequency-to-DC

converters, and similar equipment.

For every shaft revolution, 60 pulses or cycles are

produced; a shaft rotating at 1 rpm produces 60

cycles in one minute or 1 cycle per second so:

Rpm (of shaft) = Frequency in Hz

(of pickup output voltage).

The PG-100 can be equipped with magnetic pickup

M101 (standard), M102 (for low speed applications),

or any other Dynalco pickup with a pole piece of

0.106 inch diameter or less. Refer to the Dynalco

pickup catalog for full specifications and

characteristics of these pickups.

At a load resistance of 5,000 ohms or greater, 0.005

inch gap, typical ouputs are:

M101: 2 mVrms per rpm

M102: 6 mVrms per rpm

The PG-100 Rpm Pulser is designed for use over

shaft speed ranges up to 0 - 2000 rpm. It employs a

permanently lubricated, shielded, and sealed

bearing. No brushes, slip rings, or other parts that

wear out over time are used.