Description, Head load of compressor – BE Pressure supply 80 Gallon Enclosed Rotary Screw Compressor AC1080SQ User Manual

Page 10

10

Minimum Pressure Valve

As the compressed air leaves the compressor it goes through a minimum

pressure valve. This is set to maintain at least 85 psig (586kPa) in the

sump when the compressor is running. This is to insure that there is

pressure to force the oil out of the sump and through the oil system so

that sufficient oil is injected into the compressor. It is also necessary to

provide good air/oil separation. The valve acts as a check valve to

prevent back flow into the compressor from the plant system.

Cooling

The compressor has an air-cooled and after-cooler as standard. The

following are the heat loads and cooling airflow rates that must be

accommodated.

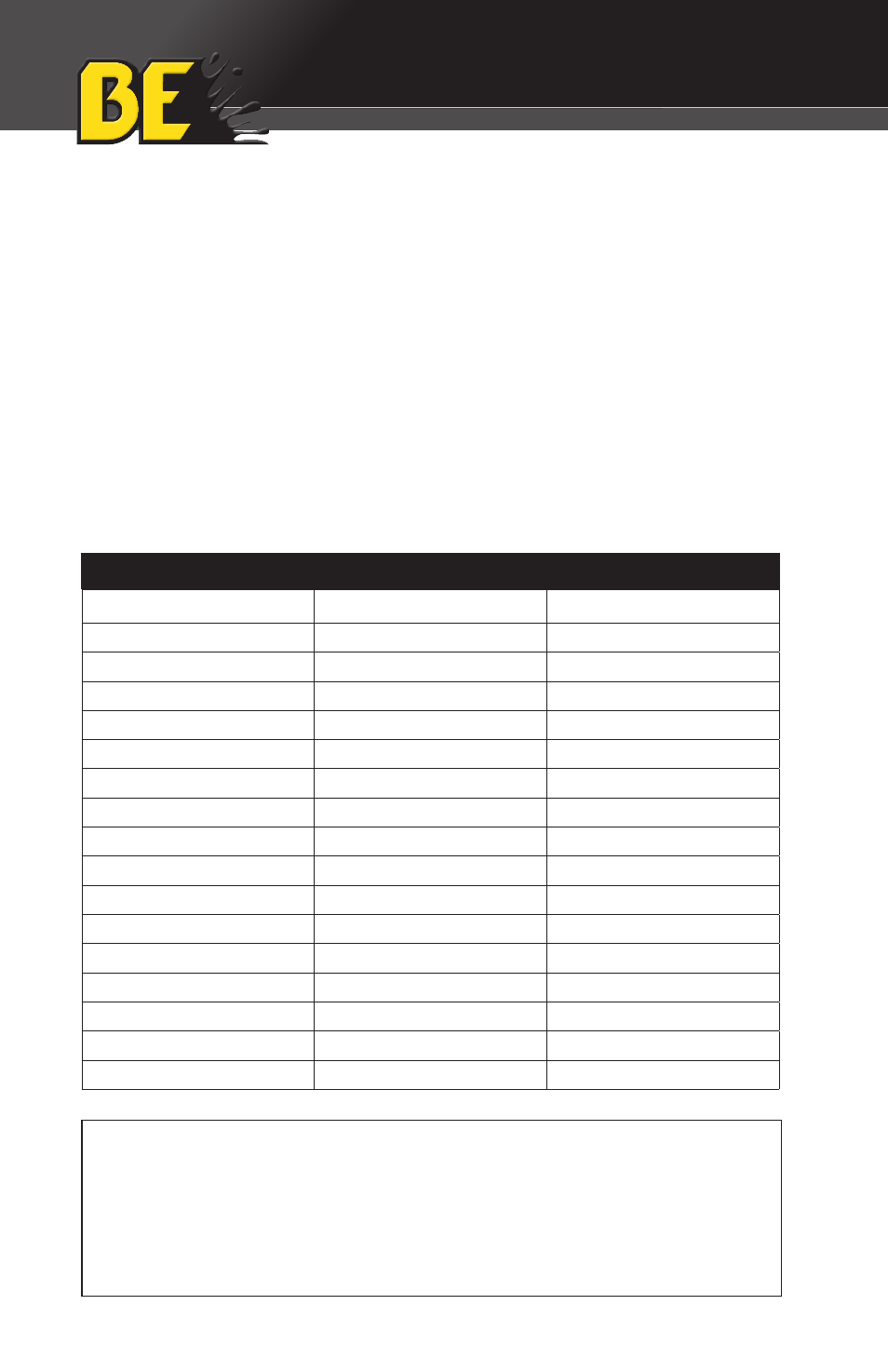

Head Load of Compressor

The compressor is an oil flooded unit. The oil lubricates, seals, and cools the

internals of the compressor.In cooling it picks up the heat generated by the

compression process and the mechanical friction from the bearings. So the oil

must be cooled to within 60 degrees Fahrenheit of the ambient temperature.

The after-cooler has been designed for a minimum approach of 15 degrees F

MODEL

TOTAL HEAT LOAD

REQUIRED FLOW

B/MIN

CFM

5-7.5HP

805

1767

10HP

1064

2335

15HP

1587

3483

20HP

2104

4619

25HP

2727

5985

30HP

3250

7134

40HP

4256

9341

50HP

5325

11,700

60HP

6390

14,040

75HP

7988

17,550

100HP

10,650

23,400

125HP

13,313

29,250

150HP

15,975

31,100

200HP

21,300

46,800

250HP

26,625

58,500

300HP

31,950

70,200

description