Description of parts, User responsibility – Amico Automatic Cryogenic Liquid Solenoid Manifold User Manual

Page 10

10

Amico Pipeline

Description of Parts

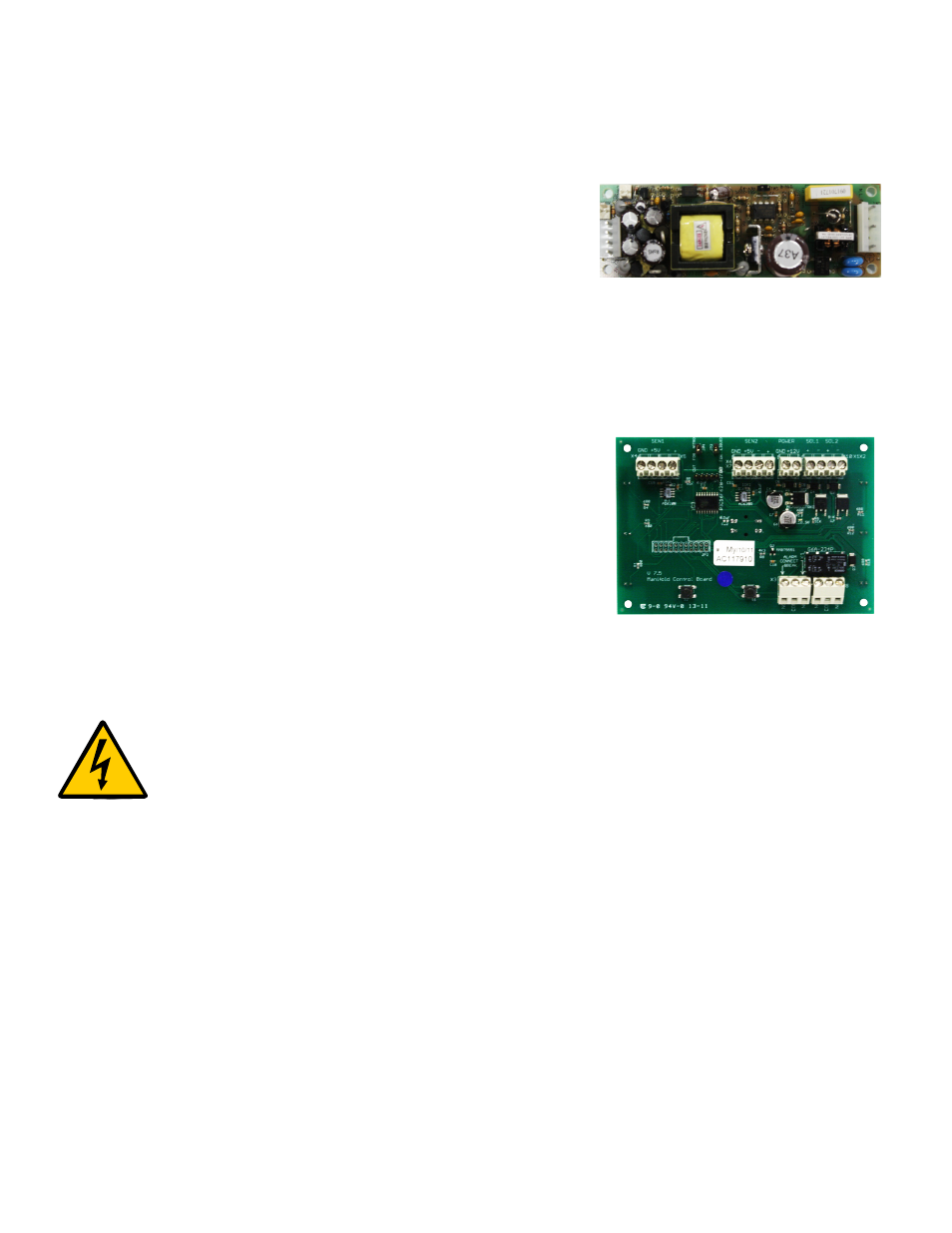

The Control Board is an electronic circuit board which controls the bank

switch-over. It monitors the pressure with the help of the bank transducers

and controls the solenoid valve in order to initiate the bank switch or

changeover. The control board illuminates the appropriate front panel

LED indicators and also provides dry contacts for connections to a remote

buzzer or an external master alarm. Power to the control board is provided

by the external power supply.

CONTROL BOARD

POWER SUPPLY

The power supply is 110 - 240 VAC, 50-60 Hz. It is mounted on the top

right hand side of the manifold and has a 1 amp fuse.

M i c r o p r o c e s s o r D i g i t a l M a n i f o l d

P a g e : 4

USER RESPONSIBILITY

The information contained in this Installation and Maintenance Manual, pertains only to the ALERT-2

microprocessor based digital manifold. This product will perform in conformity with the descriptions

contained in this manual when assembled, operated, maintained and serviced in accordance with the

installation instructions provided.

The manifold

must be checked periodically. Parts that are broken, missing, worn, distorted or

contaminated,

must be replaced immediately. Should such repair or replacement become necessary,

please contact Amico Corporation or their distributors.

Installing CO2 and N2O manifolds outdoors. Please refer to NFPA Code: 5.1.3.3.1.8 Central

supply systems for nitrous oxide and carbon dioxide shall be prevented from reaching

temperatures lower than the recommendations of the central supply system’s manufacturer,

but shall never be lower than -7°C (20°F) or greater than 54°C (130°F).

All Manifolds should not be repaired or altered without prior written approval by Amico

Corporation or it’s distributors. Failure to comply will void all warranty on the manifold.

Statements in this manual preceded by the words

WARNING, CAUTION, DANGER and NOTE are of

special significance. Please read these sections carefully.

WARNING:

denotes steps which can prevent injury.

CAUTION:

denotes steps which can prevent damage to equipment.

DANGER:

denotes steps which can prevent electrical shock to equipment or to

prevent serious injury and/or death.

DANGER: Electrical shock hazard. Ensure that the main power source is turned off during the

connection of the power supply.

GAS SERVICE IDENTIFICATION

Amico manifolds are clearly labeled for the intended gas use. The appropriate gas label is attached on the cabinet door.

There are two pipes extending from the top of the cabinet, one is for the main line pressure and the other is the vent for

the pressure relief valve, which is also labeled accordingly.

HEADER BAR CONNECTIONS

The gas-specific header bar should be attached to the inlet block on either side of the manifold. The inlet block is provided

with a sintered bronze filter and a “C” clip to secure it. The header bar should contain the proper gas connections and all

cylinder connections; as well the pigtail (hose) assemblies should comply with CGA standard B96, Compressed Gas

Cylinder Valve outlet and inlet connections.