Medical air flow calculation table – Amico CSA Triplex SCD Modular Stack Mount User Manual

Page 5

5.

Determine a routing for the intake piping and note it on the building drawings. Piping downstream of the

compressor shall be routed in a manner such that it is not subjected to temperatures lower than 4

o

C

(40

o

F).

6.

Ensure the intended location for the air plant is adequately ventilated or is at minimum air conditioned. The

plant will emancipate considerable amount of heat into the surrounding. Hence, it must be factored

in when selecting a compressor site; determining the adequacy of ventilation; or identifying BTU

requirements for air conditioning. (BTU data is furnished in the equipment data sheet).

7.

Determine the availability of electrical service.

8.

If the medical air system is not already piped to the proposed location, determine the routing for

the piping and note it on the building drawings.

6.3.2 Design

1.

Follow directions for laying out piped medical gases. This will supply a count of outlets which is

necessary for the next steps.

6.3.3 Plant Sizing

There are several available methods for sizing Medical Air. For the purpose of this design guide, only The Canadian

Standard Method (CSA) will be discussed.

The Canadian Standard Method

1.

Count all outlets in the facility

2.

Factor by facility size

3.

Please refer to Figure 2 below

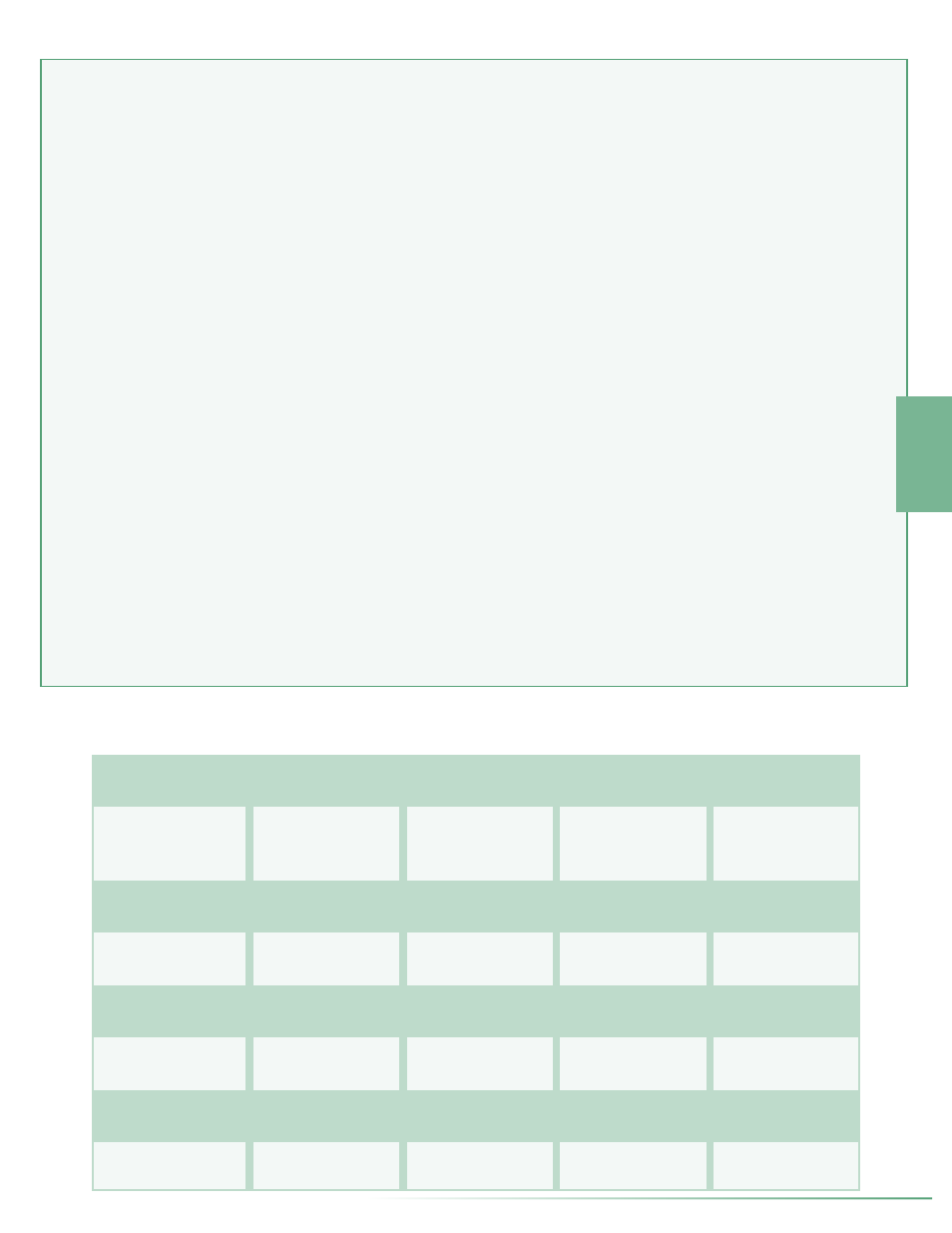

Figure 2: CSA Method - Medical Air Flow Calculation

Please refer to the table below to obtain an average flow that is required within the facility

www.amico.com

Medical Air Flow Calculation Table

Range of

Terminal Units

1-10

0

100

0

# of terminals x 25 L/

min x 100%

530 L/min + (25 L/min

x 50% x # of terminals

exceeding 25)

Total

11-25

0

75

0

26-100

0

50

0

>101

298

25

2704.5

2704.5 L/min

95.51 SCFM

250 L/min + (25 L/min

x 75% x # of terminals

exceeding 10)

1467 L/min + (25 L/

min x 25% x # of ter-

minals exceeding 100)

Actual Numbers Of

Terminal Units

Average Flow Per

Terminal Units (%)

Average Flow

Required Per

Terminal (L/min)

Total Flow

Required (L/min)

3