Great Plains 1205NT Operator Manual User Manual

Page 28

1205NT

150-131M

3/28/12

26

Coulter Down Pressure

Weights. If more weight is required for your soil

conditions, add weights to weight brackets locat-

ed on box frame. No more than 1200 pounds (600

pounds per side) should ever be added. Add an

equal amount of weight to each end of drill. See

Table 1.

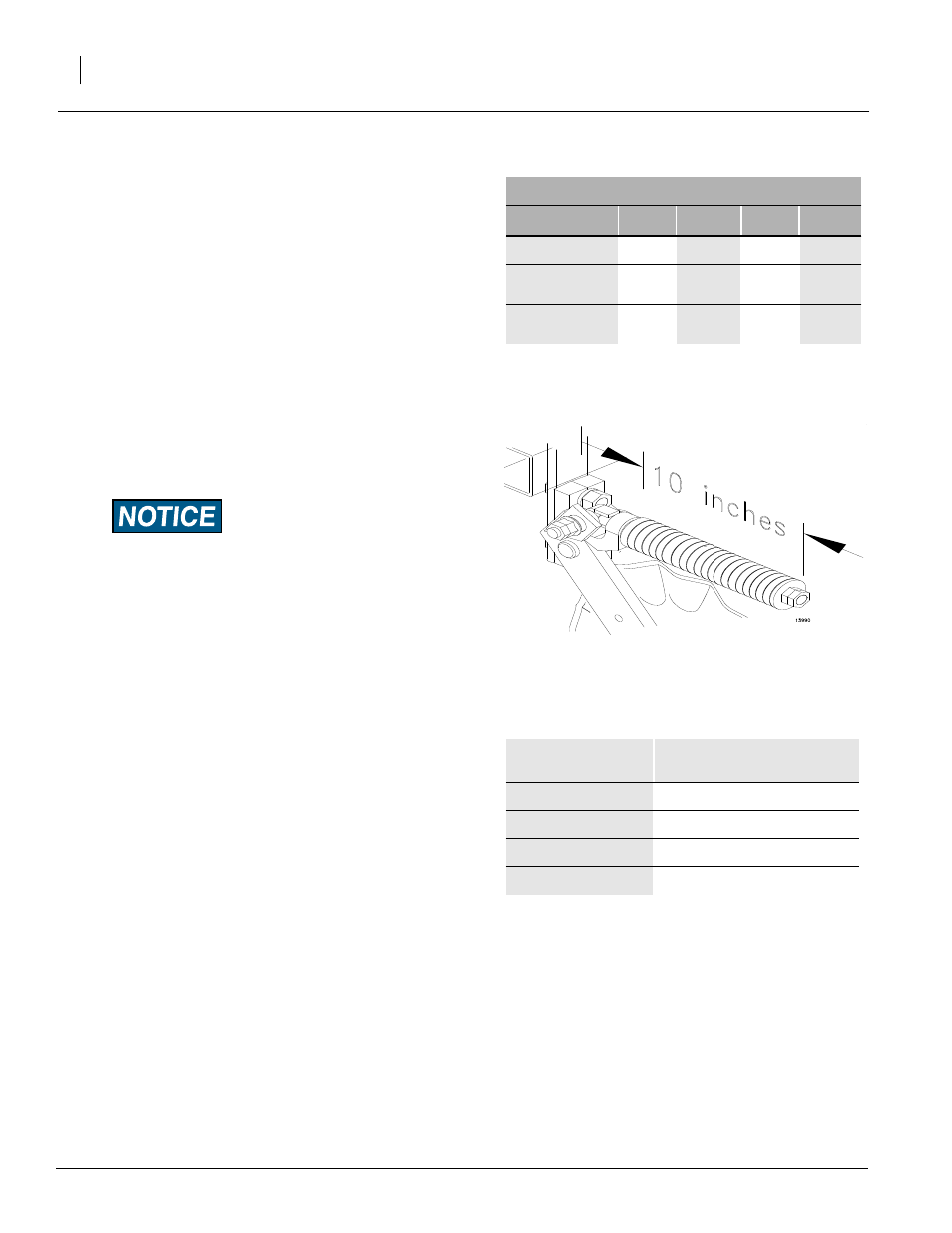

Spring Length. Coulter springs are preset at 10

inches, giving coulters an initial operating force of

400 pounds. This setting is adequate for many dif-

ficult no-till conditions.

Equipment Damage Risk:

Resetting coulter-spring length shorter than 9 3/4 inch-

es may contribute to premature failure of parts and war-

ranty will be voided. If additional force is needed, add

weights to drill.

For lighter no-till conditions where rocks or other

obstructions are a problem, you can lengthen

coulter springs to protect coulters from impact.

Refer to Table 2.

Individual Coulter Adjustment

Individual coulters can be lowered if coulters fol-

low in tractor tire tracks and do not give

satisfactory depth. To do so:

1.

Loosen 5/8 inch jam nuts on 5/8 inch square

head set screws. Then loosen set screws.

2.

Lower coulter to desired depth.

3.

Tighten set screw on side of coulter clamp

first. This squares coulter bar in clamp.

4.

Tighten set screw on front of coulter clamp.

Then tighten both 5/8 inch jam nuts on each

set screw.

NOTE: Torque 5/8 inch set screws 85-100 ft-lbs to

obtain adequate holding force.

Pounds Per Coulter

7 inch

7.5 inch

8 inch

10 inch

Empty Drill

274

282

290

363

Drill with 300

pounds added

304

314

323

406

Drill with 600

pounds added

334

345

356

449

Table 1

Weight Chart

Figure 15

Coulter Spring Length

13990

Table 2

Spring Length Chart

Spring

Length

Initial Vertical Coulter Force

10 1/2 inches

175 pounds

10 1/4 inches

300 pounds

10 inches

400 pounds

9 3/4 inches

525 pounds