5 trip reset tine hydraulics, Front of machine – Great Plains Simba Flatliner 500 FW Operator Manual User Manual

Page 25

25

Simba Flatliner 500 FW

270-600M-ENG

2013-02-06

5. Servicing and Maintenance

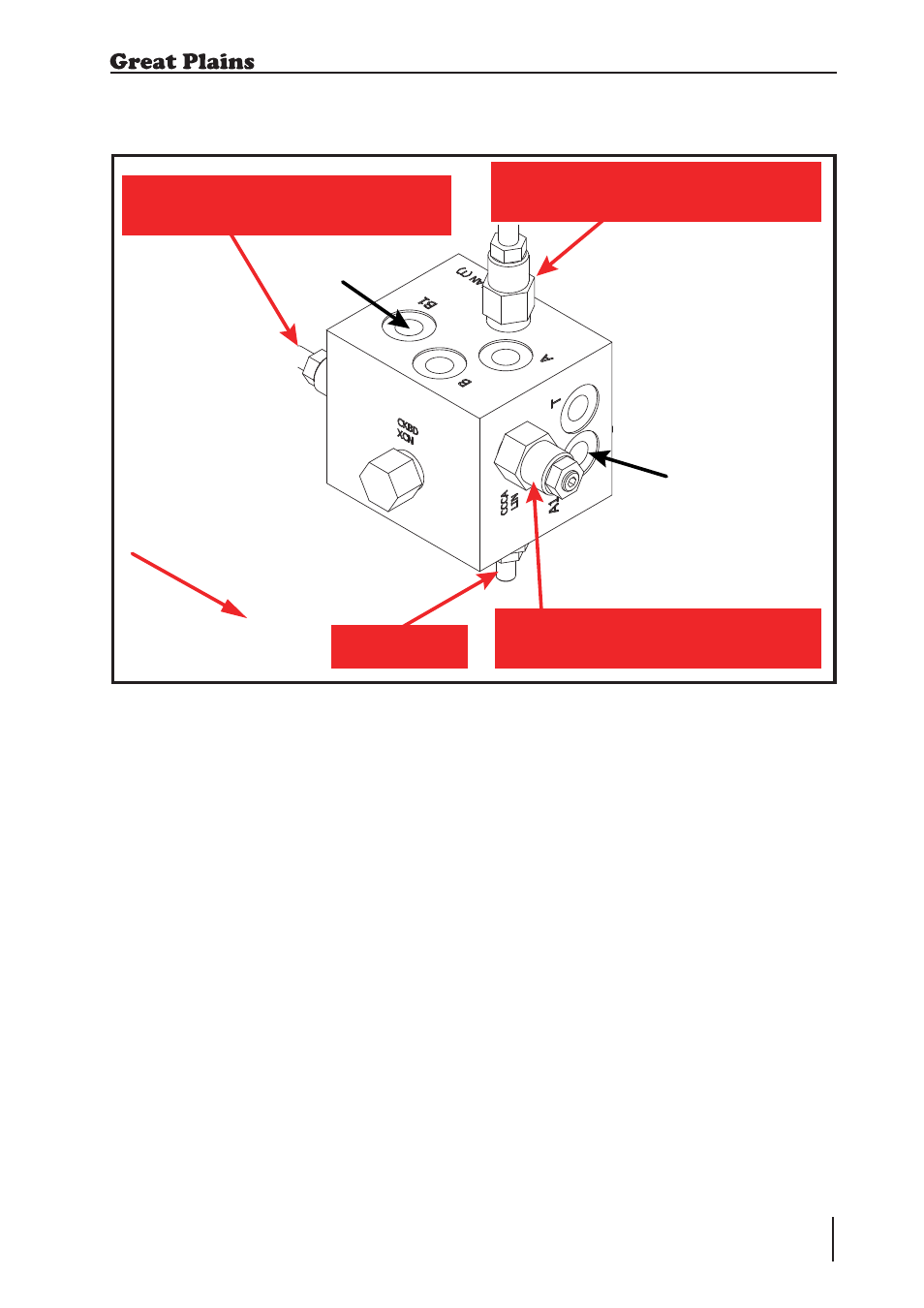

The circuit allows for the tines to be

pressurised down into work where a relief

valve allows the tine to trip up if necessary.

In normal operation, oil is locked in the

cylinder circuit at a pressure determined by

the relief valves.

De-pressurising the Circuit

To de-pressurise the circuit, identify and

adjust the following valves on the Tine

Control Manifold.

All valves can be identified by stamped

codes adjacent to each valve (above).

1

Set tractor hydraulics to neutral,

machine raised.

2

Adjust pre charge valve (

marked CCCA

LIN) fully clockwise. If necessary, note

the number of turns that it takes for the

system to be reset.

3

Adjust relief (

marked RDBA LBN) fully

anticlockwise. If necessary, note the

number of turns that it takes for the

system to be reset.

4

Set tank return line circuit to float or

down to return oil to tractor.

5

Set main system to float, or allow

oil pressure to be released in both

directions.

6

Refer to pressure gauges on machine.

Ensure both read zero before

attempting any maintenance. Repeat

the above procedure until both gauges

read zero in all circumstances.

Follow detailed setting sequence on page 26

to reset the system prior to returning to work,

or alternatively revert the above valves back

to their original setting (number of turns).

FRONT OF

MACHINE

CCCA LIN

TYPE: PRE-CHARGE VALVE

TURNING CLOCKWISE: REDUCES PRESSURE

RDBA LAN (T)

RELIEF VALVE (FAIL SAFE)

TURNING CLOCKWISE: INCREASES PRESSURE

NCBB LCN

FLOW CONTROL

RDBA LBN

RELIEF VALVE (ACCUMULATOR)

TURNING CLOCKWISE: INCREASES PRESSURE

GAUGE A

GAUGE B

5.5 Trip Reset Tine Hydraulics