6 using shims – Great Plains Simba Flatliner 500 FW Operator Manual User Manual

Page 22

22

Simba Flatliner 500 FW

270-600M-ENG

2013-02-06

If the roll is exerting too much pressure for

the conditions, but if raised will cause the

machine to operate too deeply, then draft

control may have to be used. The operating

depth can be controlled to a certain extent

by lengthening the tractor top link. This

causes the implement to run tail down and

reduces the downward thrust on the points

and wings, reducing the shattering effect of

the tines.

The lowest draught requirement is achieved

when the machine is slightly tail down (all

points touching the ground at the same

time). However the best shattering effect is

achieved when the main frame is running

level, this attitude being more desirable.

Hard/Dry Conditions

The Simba Flatliner 500 achieves best

results in dry conditions but under very hard/

dry conditions it may produce large clods of

soil at the surface. If the roll unit is unable

to break these clods down effectively this

may be overcome by removing the tines

and increasing the spacing, or an initial

precultivation at 50 to 100mm (eg. Disc)

depth to eliminate the possibility of forming

large clods from soil at this depth.

Surface Trash

The ‘ V ‘ shape of the Flatliner frame is

ideal for fields with surface trash as there

are few places for blockages to occur,

but under extreme conditions fouling may

still be evident. This can be overcome by

either increasing the mainframe to ground

clearance of the implement (by lowering the

tines in their clamps) or by removing some

tines if necessary.

4. Adjustment / Operation

4.6 Using Shims

Before using shims to alter machine settings

ensure the machine is stationary and the

tractor is turned off with the keys out. Ensure

that all operators are clear of the machine

and that no load is being held on any existing

shims in the cylinder / depth control rod.

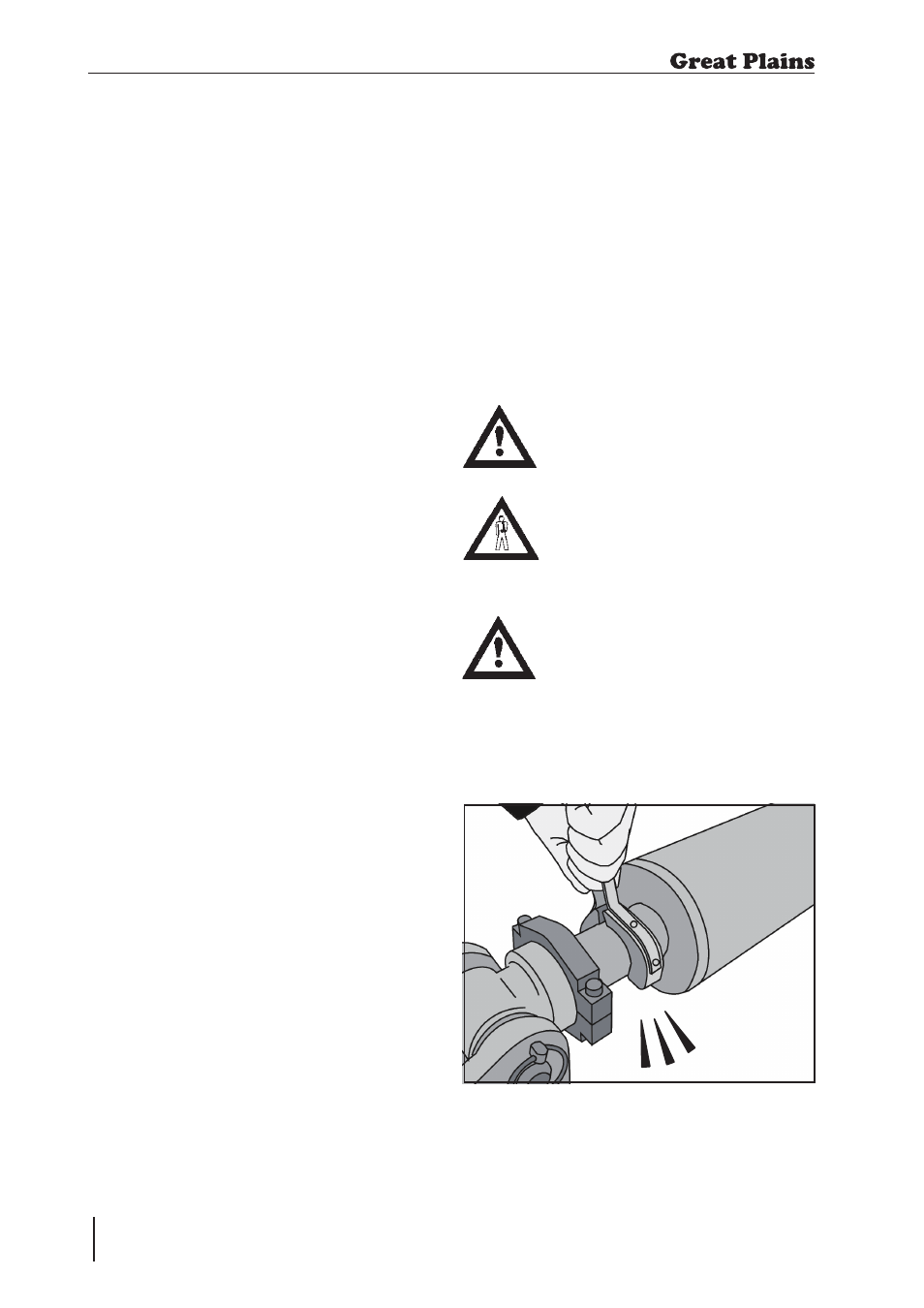

To fit the shims hold them by the handle and,

using a firm action, clip them onto the rod

as shown in Fig. 4.05. They are removed by

using a finger to pull firmly on the handle.

Check the cylinder / depth control

rod for damage and debris before

fitting shims.

Only attempt to add or remove

shims using the handle. Trying to

manipulate shims using the jaws

could result in injury.

When changing machine settings

ensure both sides of the machine

mirror each other. The left hand

cylinder should contain the same

amount of shims as the right, for

example. Failure to do this could

result in damage to the machine.

Fig. 4.05: Shims