Hydraulic cylinder mounting locations – Great Plains ADI445 Operator Manual User Manual

Page 15

13

Section 1 Assembly and Setup

5/11/05

Model 2250 Air Drill Implement 160-192M

Great Plains Mfg., Inc.

15149

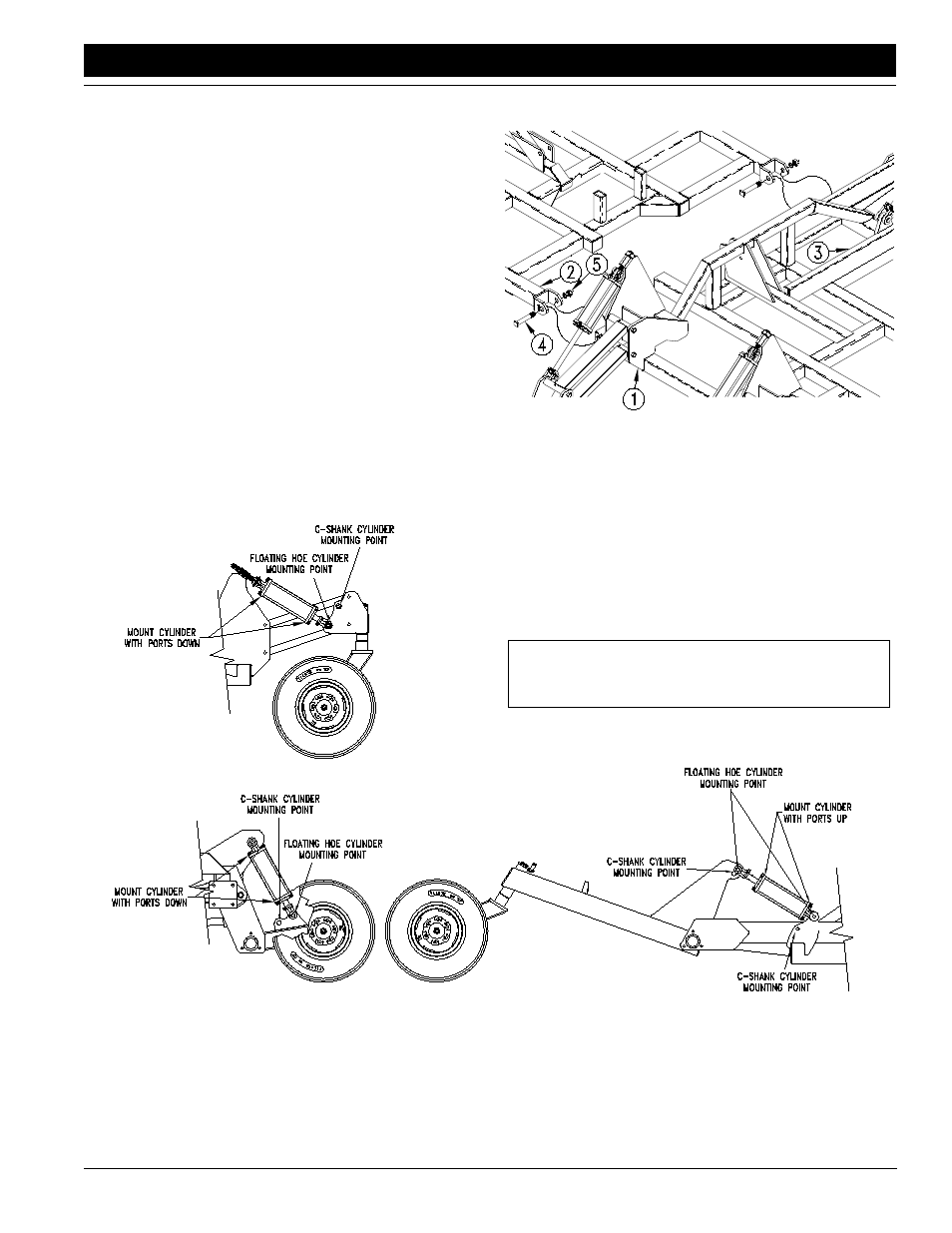

Hydraulic Cylinder Mounting Locations for Floating Hoe vs. Spring Shank

Figure 1-5

Dual Gauge Wheels

Wing Lift Assist

Connect frame section two (#2) to frame section three (#3)

using two pivot clevis bolts (#4) and 1” lock nuts (#5). Make

sure the pivot clevis bolt heads are oriented to the outside

of the clevis and seated next to the welded key stock on

the clevis. This will prevent rotation of the bolt in the clevis.

Repeat the above steps when joining frame section five to

frame section four.

Refer to Figure 1-4:

Move frame section one (#1) so that the pivot bushing end

is aligned with the clevis end of frame section two (#2). Be

sure frame section one is not confused with frame section

six. This can be avoided by making sure the lift assist arms

(#3) are positioned in the same direction as that of frame

sections three and four.

Connect frame section one (#1) to frame section two (#2)

using two pivot clevis bolts (#4), and 1” nuts (#5). Make

sure the pivot clevis bolt heads are oriented to the outside

of the clevis and seated next to the welded key stock on

the clevis.

Repeat the above steps when joining frame section 6 to

frame section 5.

The frame sections should now be assembled and still

supported by the shipping stands.

Hydraulic Cylinder Mounting Locations

Refer to Figure 1-5:

Frame Sections #1 & #2, and #5 & #6 Assembly

Figure 1-4

15110

NOTE: Failure to correctly mount cylinders could

cause damage to the implement voiding the warranty.