Troubleshooting – Great Plains 3P300 Operator Manual User Manual

Page 20

18

Section 4 Troubleshooting

3/6/06

3P200 and 3P300 Three-Point Sprayer 500-103M

Great Plains Mfg., Inc.

Section 4

Troubleshooting

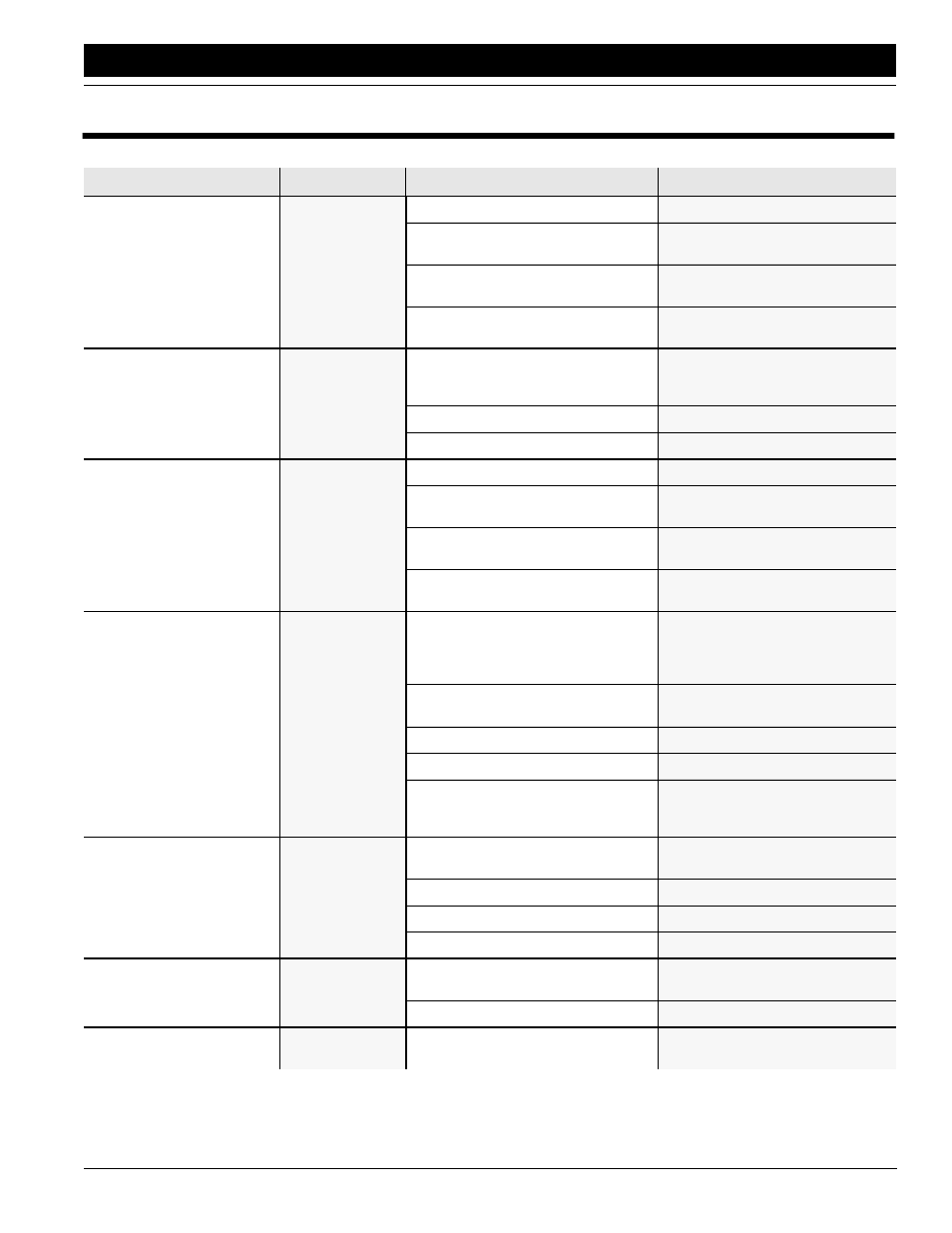

Problem

Problem Area

Specific Checks

Solutions

Pressure decreasing

Between gauge

and liquid supply

Pump wearing

Rebuild or replace pump

Plugged suction or pump to pressure

head hose

Clean hose and reduce cause of

clogging

Plugged Whirlfilter

Clean out Whirlfilter, refer to

pages 12 & 13

Plugged gauge

Remove the quick disconnect fitting

and flush gauge protector

Pressure fluctuating

Between pump

outlet and liquid

Check suction hose & fittings for air

leaks. Air in system is indicated by

buffs of air at nozzles

Remove obstruction from clogged

area

Vortex in tank suction

Align agitators properly

Cracked pump housing

Replace pump housing

Pressure increasing

Between gauge

and nozzle

Nozzle screens clogged

Clean screens

Nozzle orifices plugged

Remove material with soft brush or

air

Boom hoses becoming clogged

Remove obstruction from clogged

area

Boom hoses pinched

Use cable ties to position hose so it

will not kink

Pressure cannot increase

Pump or electric

ball valve

From nozzle charts check liquid

demand against pump capacity (noz-

zle requirement + agitation require-

ment)

Reduce swath width by nozzle

reduction; install smaller nozzles

and drive at a lower rate of speed

Electric ball valve or gauge not func-

tional

Replace or repair

Pressure adjust switch faulty

Test switch & replace if faulty

Fuse is out in control box

Replace fuse

Manual pressure adjustment valve not

all the way open

Open the manual pressure valve all

the way and allow the electric ball

valve to govern the pressure

No pressure

Plumbing

Tank shut-off valves off

Make sure all tank shut-off valves

are open

Loose fittings

Tighten fittings so pump can prime

Collapsed suction hose to pump

Replace hose

Obstruction in suction hose or tank

Remove obstruction

No pressure

Pump

Hydraulic pump running in the wrong

direction

Switch hydraulic hoses in the tractor

outlet

PTO pump coupler loose

Tighten PTO coupler

Pressure cannot decrease

Pump or electric

ball valve

Tank agitation restricted

Check that the agitator valve is open

and that the liquid is being agitated