Elevator slide adjustment – Great Plains 3P300 Operator Manual User Manual

Page 19

17

Section 3 Adjustments

3P200 and 3P300 Three-Point Sprayer 500-103M

3/6/06

Great Plains Mfg., Inc.

ed. Refer to Calibration Procedures in the Application

Guide.

The electric ball valve is used to adjust the pressure to the

booms. It is controlled with the pressure adjust switch on

the control box. The boom pressure is displayed by the

boom pressure gauge.

To adjust the pressure, hold the pressure adjust toggle

switch up for more pressure, down for less pressure.

As the tank level decreases, the boom pressure may

change. Check boom pressure gauge frequently and

make sure that the pressure doesn’t change. Generally,

the boom pressure will need to be adjusted up slightly

when the tank level decreases.

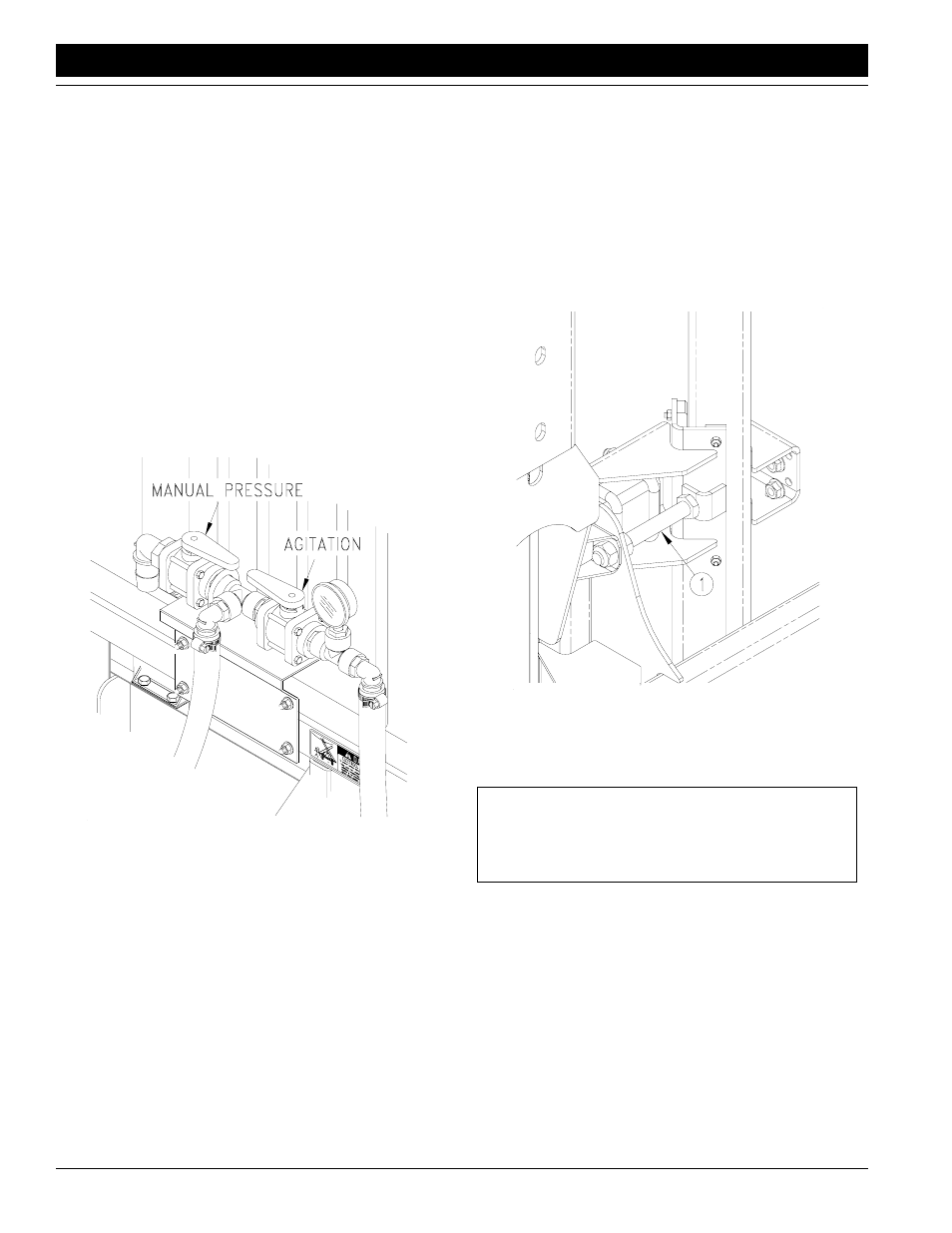

When the manual pressure adjustment valve, Figure 3-2,

is wide open, the pressure adjust switch is very sensitive.

To decrease the sensitivity of the pressure adjust, set the

manual pressure adjustment valve. Refer to Manual Pres-

sure Valve in the “Operating Instructions” section on

page

Agitation Valve/Manual Pressure Valve

Figure 3-2

15783

Elevator Slide Adjustment

The elevator slide is initially adjusted at the factory so that

the slide blocks have the correct tolerances between the

blocks and the vertical elevator tuber. Over time the

blocks will wear and may need to be adjusted. To adjust

the slide blocks, adjust the slide block clearance bolts (#1)

so that the slide frame is centered and parallel with the el-

evator frame. Make sure all blocks have 1/32 of an inch

clearance between the block and the vertical tube when

finished.

Elevator Slide Adjustment

Figure 3-3

15803

IMPORTANT: With the boom mounted, there will be

1/16 of an inch clearance on the top rear and lower

front blocks. The other blocks will be touching the

tube due to the weight of the boom.