Bleeding fold hydraulics, Unfolded bleeding – Great Plains LC40 Operator Manual User Manual

Page 41

Great Plains Manufacturing, Inc.

Maintenance and Lubrication

37

2014-07-21

591-049M

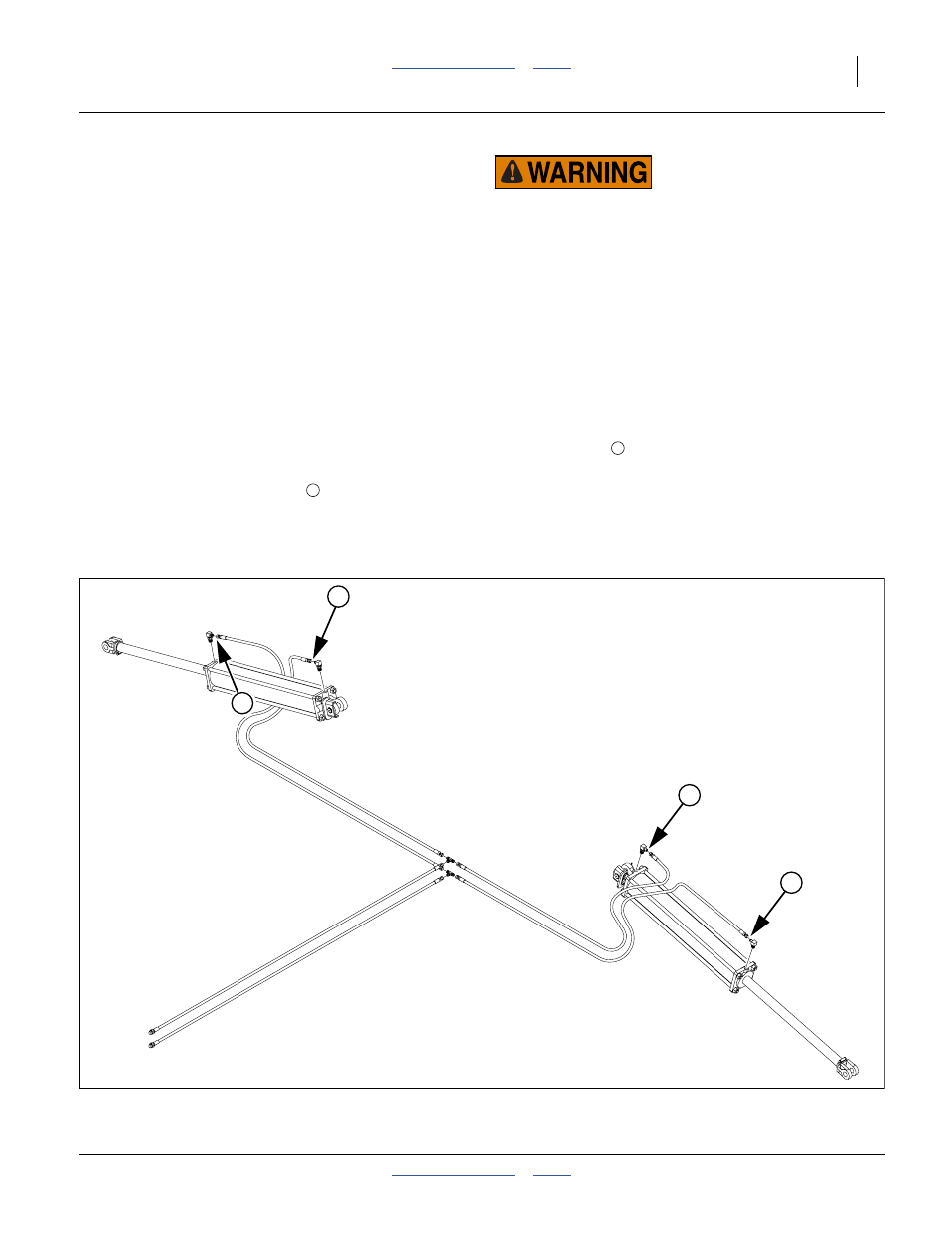

Bleeding Fold Hydraulics

To function properly, the hydraulics must be free of air. If

hydraulics have not been bled, they will operate with

jerky, uneven motions and could cause wings to drop

rapidly during folding or unfolding. If hydraulics were not

bled during initial implement setup or if you replace a

part in hydraulic system during the life of the implement,

complete the following procedures.

Unfolded Bleeding

Refer to Figure 31

1.

Check hydraulic fluid level in tractor reservoir and fill

to proper level. Add fluid to system as needed.

2.

With implement unfolded and fold cylinders

completely extended, disconnect rod end pins and

swing the cylinders so they will not contact anything

when extended.

3.

Loosen rod end hose fittings

Note: Do not loosen an O-ring boss (ORB) connection

for bleeding. Bleeding at an ORB damages the

seal.

4.

Slowly supply oil to rod end of fold cylinders until oil

appears at loosened hose fitting. Tighten fitting and

completely retract fold cylinders.

5.

With cylinders completely retracted, loosen base end

hose fittings

6.

Slowly supply oil to base end of fold cylinders until oil

appears at loosened hose fitting. Tighten base end

hose fitting and cycle fold cylinders in and out

several times.

7.

Re-pin cylinder rod clevises.

High Pressure Fluid Hazard:

Relieve pressure before disconnecting hydraulic lines.

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin causing serious injury. Use a piece of paper

or cardboard, NOT BODY PARTS, to check for leaks. Wear

protective gloves and safety glasses or goggles when working

with hydraulic systems. If an accident occurs, seek immediate

medical attention from a physician familiar with this type of

injury.

Figure 31

Bleeding Fold Hydraulics

34909

1

2