Quick setup guide for intelliag model nta – Great Plains DICKEY-john IntelliAg Quick Start User Manual

Page 4

Quick Setup Guide for IntelliAg Model NTA

11001-1460C-201107

©2011 DICKEY-john Corporation

Specifi cations subject to change without notice.

STEP 7: Ground Speed Calibration Setup

Press the Speed Set button

.

Enter desired values using Table H as reference.

Press the Work Screen button

when Ground Speed Calibration confi gura-

tions are complete to return to the Main Work screen.

1.

2.

3.

TABLE H:

Ground Speed

Setup

Default Value or

Value to Enter

Instructions/Defi nitions

Source

Digital Frequency

Select CAN Ground if radar is connected to ISO tractor cab har-

ness. Select Digital Frequency if radar or hall-effect is connected

to WSMT actuator harness.

Gspd Constant

3440 Pul/400 Ft

Input based on pulse count produced by the ground speed

sensor over 400’ distance. See Operator’s manual for calibration

instructions.

Shutoff Speed

0.01 mph

0.02 kph

Indicates the minium ground speed allowed before the system

shuts off all control channels.

Min Override

0.0 mph

0.0 kph

Minimum Override takes over when actual ground speed is below

the designated value. The control operates at this speed until

actual ground speed rises above the minimum override speed or

the actual speed drops below the shutoff speed.

Master Switch

Timeout

5 sec

Determines the length of time before the system disables the

operate function after ground speed is 0 if the master switch

remains in the ON position.

Ground Speed

Failure Alarm

Delay

5 sec

Set to desired number of seconds alarm sounds after the ground

speed is zero and seed fl ow continues. (monitor only)

Implement Lift

Enabled

Implement lift switch must be in the down position to operate.

STEP 8: Accessory Sensor Setup

Hopper Setup

Press the Module Confi guration button

.

Press the Hopper Assign button

.

Verify # of hoppers is correct or enter # of hoppers assigned.

Press the Hopper Set button

.

Enter desired values using Table I as reference.

RPM Sensor Setup

Press the RPM Module button

.

Enter # of RPM sensors, if required.

Press the RPM Setup button

.

Enter desired values using Table I as reference.

Pressure Sensor Setup

At the Module Confi guration screen, press the PSI Module button

.

Verify # of pressure sensors or enter the # of pressure sensors assigned.

Press the Pressure button

.

Enter desired values using Table I as reference.

For additional information regarding hopper level, RPM, and pressure sensor setup,

reference the Operator’s manual.

1.

2.

3.

4.

5.

6.

7.

8.

9.

9.

10.

11.

12.

4

TABLE I:

Accessory

Setup

Default Value or

Value to Enter

Instructions/Defi nitions

# of Hoppers

2

# of hopper sensors connected to each module. # of hopper data

items for each listed module and the Hopp #’s value will automati-

cally populate if Auto Confi g is used to confi gure installed sensors.

Hopper Logic

Level

Active Lo

Sets the active state to low signifying that an alarm is generated

if the sensor’s output is in a low state. Use this setting if the con-

nected sensor outputs a low condition when empty similar to the

DICKEY-john hopper sensor.

Hopper Alarm

Delay

5 sec

Controls the delay time between the detection of a high/low hop-

per alarm condition and the generation of the resulting alarm. The

value is entered in seconds.

Channel

(Hopper #1)

1

Assigns hopper sensor 1 to channel 1.

Channel

(Hopper #2)

2

Assigns hopper sensor 2 to channel 2.

# of RPMs

1

Number of RPM sensors connected to each module to monitor a

shaft/fan.

High Alarm

4100 RPM

Sets the RPM value at which a high RPM warning error is gener-

ated.

Low Alarm

2500 RPM

Sets the RPM value at which a low RPM warning error is gener-

ated.

High Alarm Delay

5 sec

Establishes the delay between the detection of a high RPM alarm

condition and the resulting alarm display (entered in seconds).

Low Alarm Delay

5 sec

Establishes the delay between the detection of a low RPM alarm

condition and the resulting alarm display (entered in seconds).

RPM Constant

3 pul

Number of pulses per sensor revolution.

RPM Filter

50%

Filters the signal out of the RPM sensor.

Disable Control on

Low Alarm

Disabled

Allows for disabling of all control channels if the RPM value of the

selected sensor falls below the low alarm level setting.

# of Pressure

Sensors

2

Number of pressure sensors connected to each module to monitor

pressure.

High Alarm

20 oz/in

2

Sets the pressure value at which a high pressure warning error is

generated (oz/in

2

).

Low Alarm

4 oz/in

2

Sets the pressure value at which a low pressure warning error is

generated (oz/in

2

).

High Alarm Delay

5 sec

Establishes the delay between the detection of a high pressure

alarm condition and the resulting alarm display (entered in

seconds).

Low Alarm Delay

5 sec

Establishes the delay between the detection of a low pressure

alarm condition and the resulting alarm display (entered in

seconds).

Pressure Filter

50

Filters the signal out of the pressure sensor.

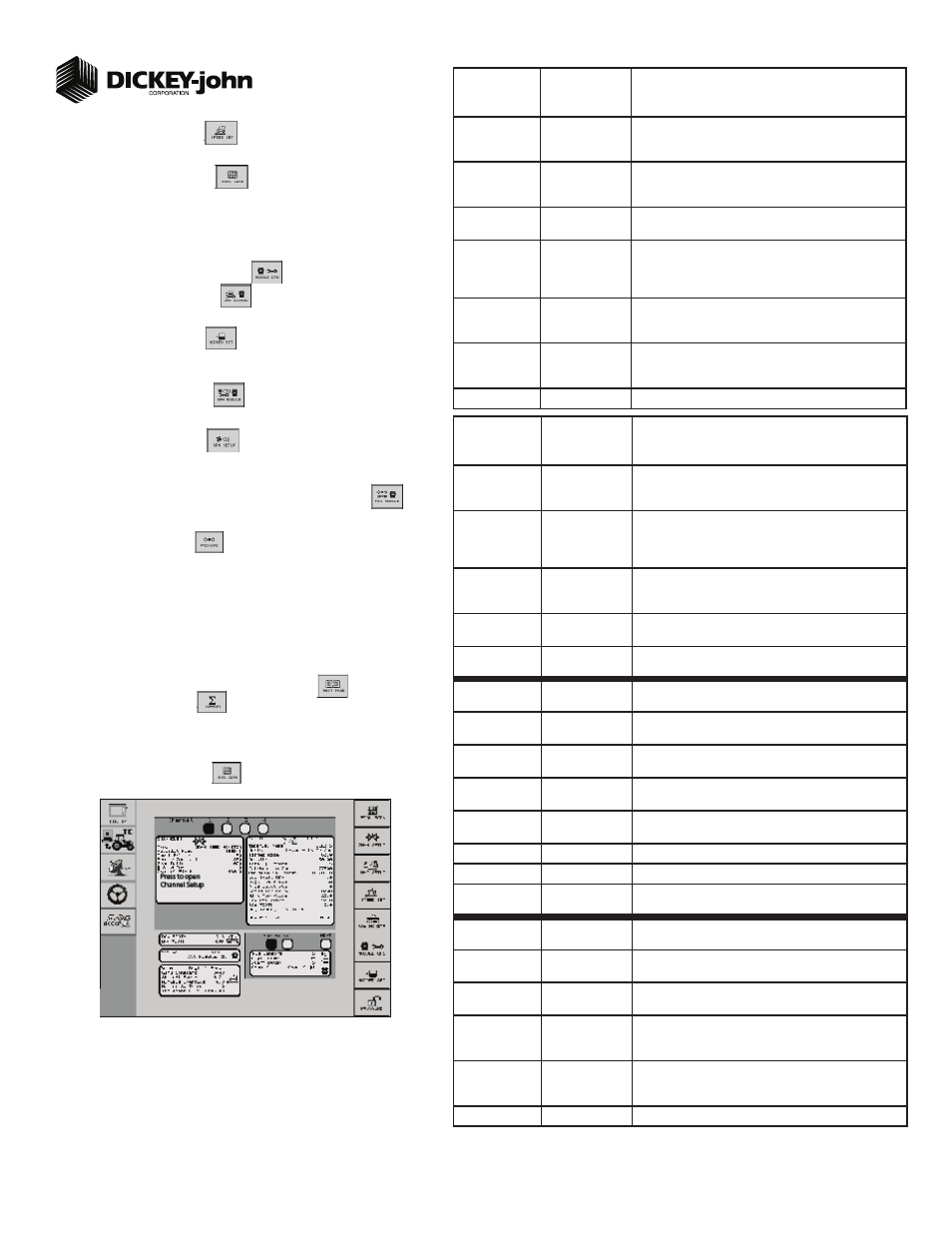

STEP 9: Summary Screen

The Summary screen provides an overview of setup constants for active control chan-

nels.

At the Main Work screen, press the Next Page button

.

Press the Summary button

To view specifi c control channel confi gurations, press the respective control chan-

nel box 1-4.

Press inside a yellow highlighted box to open a specifi c screen for editing.

Press the Work Screen button

to return to the Main Work screen.

1.

2.

3.

4.

5.

Summary Screen