Drill assembly components, Pre-assembly checklist, General description – Great Plains 3S-3000F Predelivery Manual User Manual

Page 5

3

Section 1 Assembly

8/9/06

3S-3000 Three-Section Folding Drill 195-144M

Great Plains Mfg., Inc.

Section 1

Assembly

Having all the parts and equipment readily at hand will

speed up your assembly task and make the job as safe as

possible.

Drill Assembly Components

Wide Loaded Drills

•

Drill Assembly (Complete drill less wing

walkboards, press wheel arms, press wheels and reflec-

tor decals)

•

Press Wheel Arms

(1 Per row for each wing frame opener)

•

Press Wheels (1 Per row for each wing frame opener)

•

Wing Walkboards (2)

•

Red and Amber Reflector Decals

•

Acre Meter

•

All fasteners and misc. components are located

in their assembly location

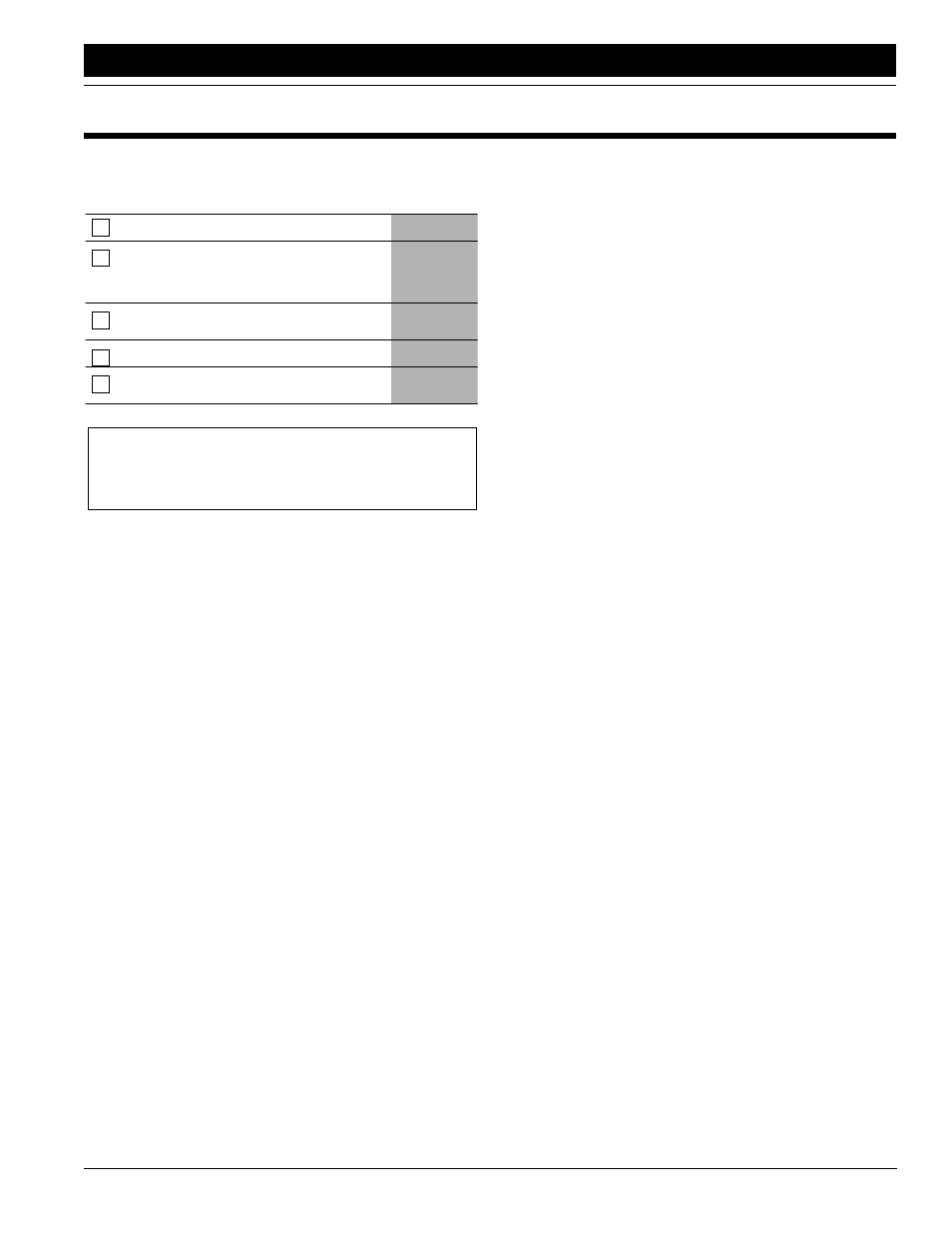

Pre-Assembly Checklist

Check

Reference

All major frame components

This Manual

Fasteners and pins that were shipped with the drill.

NOTE: If a pre-assembled part or fastener is tempo-

rarily removed for assembly reasons, remember where

it goes. Keep the parts separated.

This Manual

Inflate tires to specified air pressure. Tighten wheel

bolts to specified torque.

Oper. Manual

Section 8, pg. 43

Have a minimum of 2 people at hand while assembling drill.

This Manual

Have a fork lift or hoist along with chains and safety

stands that are sized for the job ready for assembly task.

This Manual

NOTE: In the illustrations all related components may

not be shown. This is to help clarify instructions that go

with the illustration.

Standard Legal Width Loads

•

Tongue and Mainframe Assembly or

Mainframe Assembly less Tongue

Tongue Assembly

•

Center Box Frame Assembly

•

Right Hand Wing Box Frame Assembly

•

Left Hand Wing Box Frame Assembly

•

Transfer Drive Shaft Assembly

•

Acre Meter

•

All fasteners and misc. components are located

in their assembly location

General Description

This manual was written to aid in the assembly and prep-

aration of a new drill that is delivered by Great Plains

Trucking network. The manual includes, assembly instruc-

tions, leveling instructions, and hydraulic bleeding instruc-

tions. It is recommended to bleed and charge all hydraulic

circuits before attempting to make leveling adjustments.

The hydraulics can aid in the leveling and drill preparation

process. Read and understand the “Important Safety In-

formation” section on pages 1 through 7 of the operators

manual before you start. It is the responsibility of the deal-

er to unload, assemble, and prepare the drill for use.

Tools required

•

Fork lift, overhead hoist, or loader

•

General hand tools