Assembly instructions, Marker assembly, Assembly – Great Plains 2SNG30 Assembly Instructions User Manual

Page 2

2

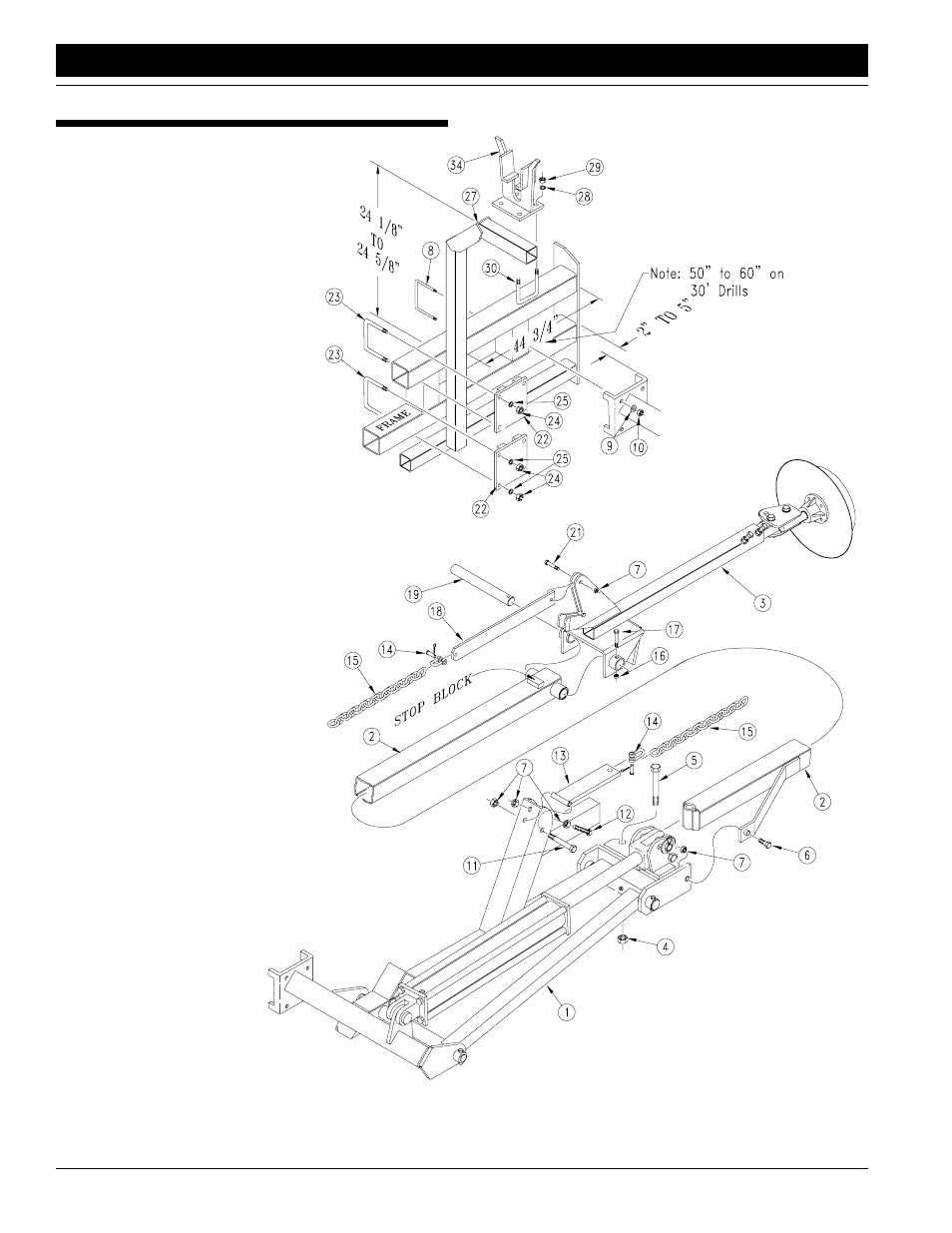

Two-Section, Hydraulic Folding Marker 113-329M

8/21/06

Great Plains Mfg., Inc.

Assembly

Assembly Instructions

Marker Assembly

1.

Lower drill into field position. Make sure the

assembly area is large enough for the drill

and markers (62 feet for a 30-foot drill or 50

feet for a 24-foot drill).

2.

Attach the marker first section with mount

(1) to the lower 3 1/2-inch tube of the

drill frame. Mount the 5/8-inch u-

bolts (8), lock washers (9) and hex

nuts (10).

NOTE: On 24-foot drills with dual gauge

wheels, markers may not be applicable

due to problems with clearance. If using

markers on a dual gauge wheel 24’ drill,

mounting the markers and the marker carrier

arm on the top frame tube will be acceptable. It

may also be necessary to move the gauge

wheel assembly towards the inside of the drill.

3.

Assemble the marker in a horizontal posi-

tion. Remove the port plugs in the hydraulic

cylinder then fold the first section and the lift

lug (1) to a horizontal position.

4.

With the stop block positioned on top of second section (2),

align the holes of the second section with the holes of the

first section (1) and bolt together with 5/8-by-5 1/2-inch bolt

(5), lock nut (4), 3/8-by-2-inch shear bolt (6) and lock nut (7).

5.

Place the third section (3) over the end of the second sec-

tion (2) and insert hinge pin (19) through the second and

third section pivot. Secure the hinge pin (19) with

1/4-by-2-inch bolt (17) and lock nut (16).

6.

Bolt the chain bar weldment (13) to the first section

(1) with 3/8-by-3 1/4-inch bolt (11) and lock nut

(7). The chain bar weldment (13) should pivot

freely on the 3/8-inch bolt (11). Bolt the

chain bar (18) to the third section (3)

with the

3/8-by-1 1/2-inch bolt (21) and lock nut

(7). The chain bar (18) should pivot

freely on the 3/8-inch bolt (21). Con-

nect the marker chain (15) between

the chain bar (18) and chain bar

weldment (13) with 5/16-inch utility clevis

(14). With the marker disk adjusted for

seeding width and disk touching the

ground, adjust chain length to remove

the slack. Adjustment should be made at

the utility clevis (14) nearest to the drill.

7.

Position the 3/8-inch stop bolt (12) and lock

nuts (7) in the lift arm (1) so the head of the stop bolt extends

as little as possible. After marker is folded, adjust stop bolt to

tighten chain.

8.

When mounting marker carrier (27), mount the marker car-

rier arm (27) to drill frame as noted in the illustration. Use the

clamp plates (22), 1/2-by-3 1/2-by-6 1/2-inch u-bolts (23),

lock washers (25), and hex nuts

(24). The carrier arm (27) should

be set 24 1/8 inches above

the drill frame.

NOTE: On 24-foot drills with

dual gauge wheels, mount carri-

er on top tube only. Discard one

clamp plate and its mounting

hardware. Set carrier arm (27) 32 5/8 inch-

es above drill frame.

NOTE: On bean machines, use 1/2-by-7 1/32-by-8-

inch u-bolts to mount larger clamp plates on top frame

tube.

Figure 1

Marker Assembly

11007